AERCO SmartPlate User Manual

Page 72

SmartPlate Installation, Operation & Maintenance Manual

CHAPTER 8 – CORRECTIVE MAINTENANCE

Page 72 of 138

AERCO International, Inc.

100 Oritani Dr. Blauvelt, NY 10913

OMM-0069_0E

PRI: 11/26/2013

Phone: 800-526-0288

SP-100

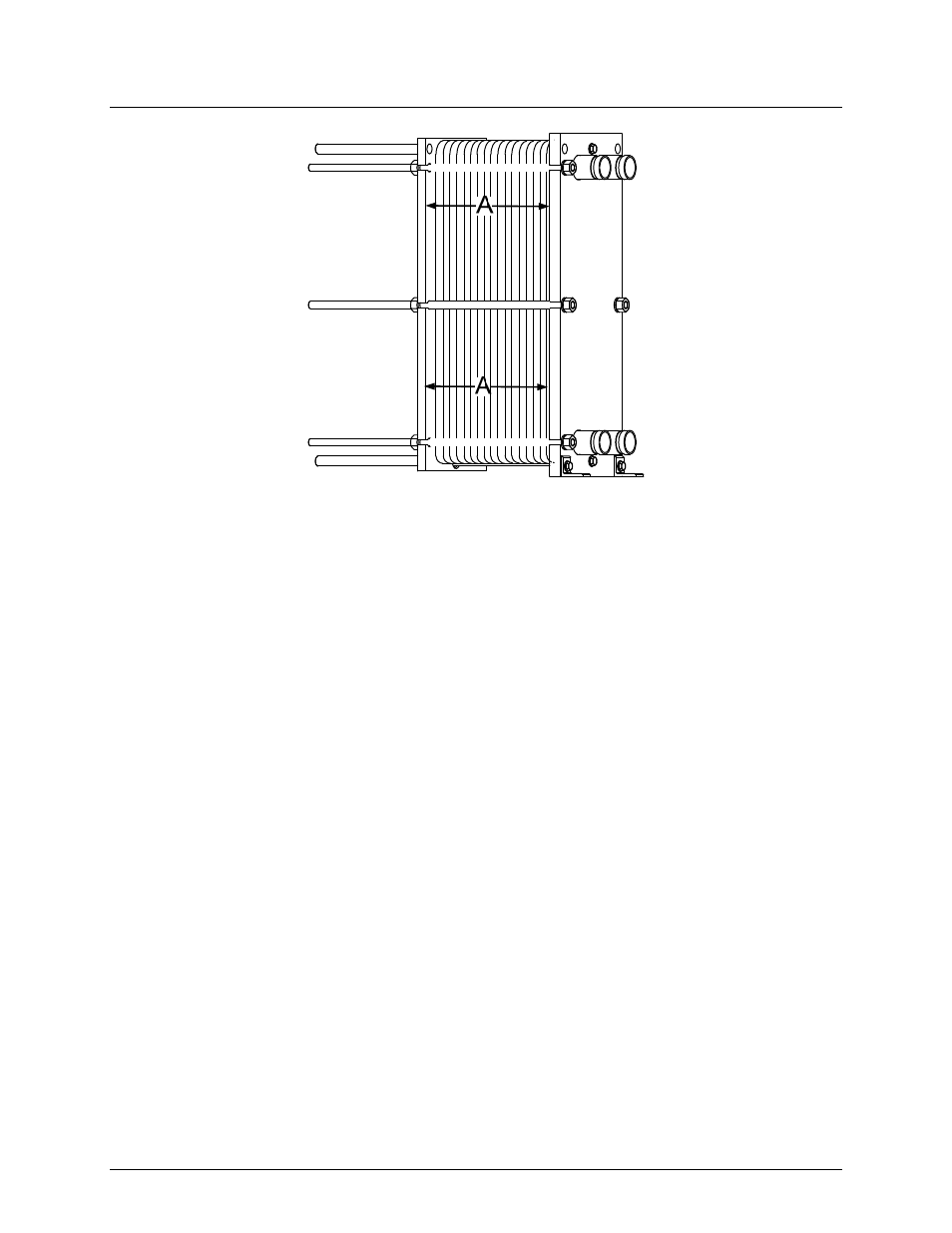

Figure 8-13. Tightening Plate Pack Bolts

9. Check the plate pack length ("A") during closing in at least four locations close to the bolts

being used.

10. Place the remaining bolts in position and tighten them.

11. Next, insert the corner bolts and tighten, maintaining dimension "A" of drawing- To avoid

damaging the channel plate corners, it is important that the corner bolts are not used for

closing the Heat Exchanger.

12. The nominal plate pack length "A" can be exceeded in some cases. The tightening can be

stopped at "A" + 2% and pressure tested.

NOTE

When a pneumatic tightening device is used, it should be set at

the maximum tightening torque of 550 Lb-Ft for 3/4" bolts.

Dimension "A" must, however, s t i l l be measured during

tightening.

When the bolts are tightened by hand using a wrench, the

tightening moment is estimated.

IF DIMENSION "A" IS NOT REACHED WITH APPLICATION

OF MAXIMUM TIGHTENING TORQUE:

Check the number of plates and dimension "A".

Check that all nuts are running freely. If not, clean and

lubricate or replace.

Fit all bolts and tighten alternately.