AERCO SmartPlate User Manual

Page 48

SmartPlate Installation, Operation & Maintenance Manual

CHAPTER 7 – TROUBLESHOOTING

Page 48 of 138

AERCO International, Inc.

100 Oritani Dr. Blauvelt, NY 10913

OMM-0069_0E

PRI: 11/26/2013

Phone: 800-526-0288

SP-100

5. Refer to the applicable procedures in Chapter 8 – CORRECTIVE MAINTENANCE if

component removal and/or replacement is required.

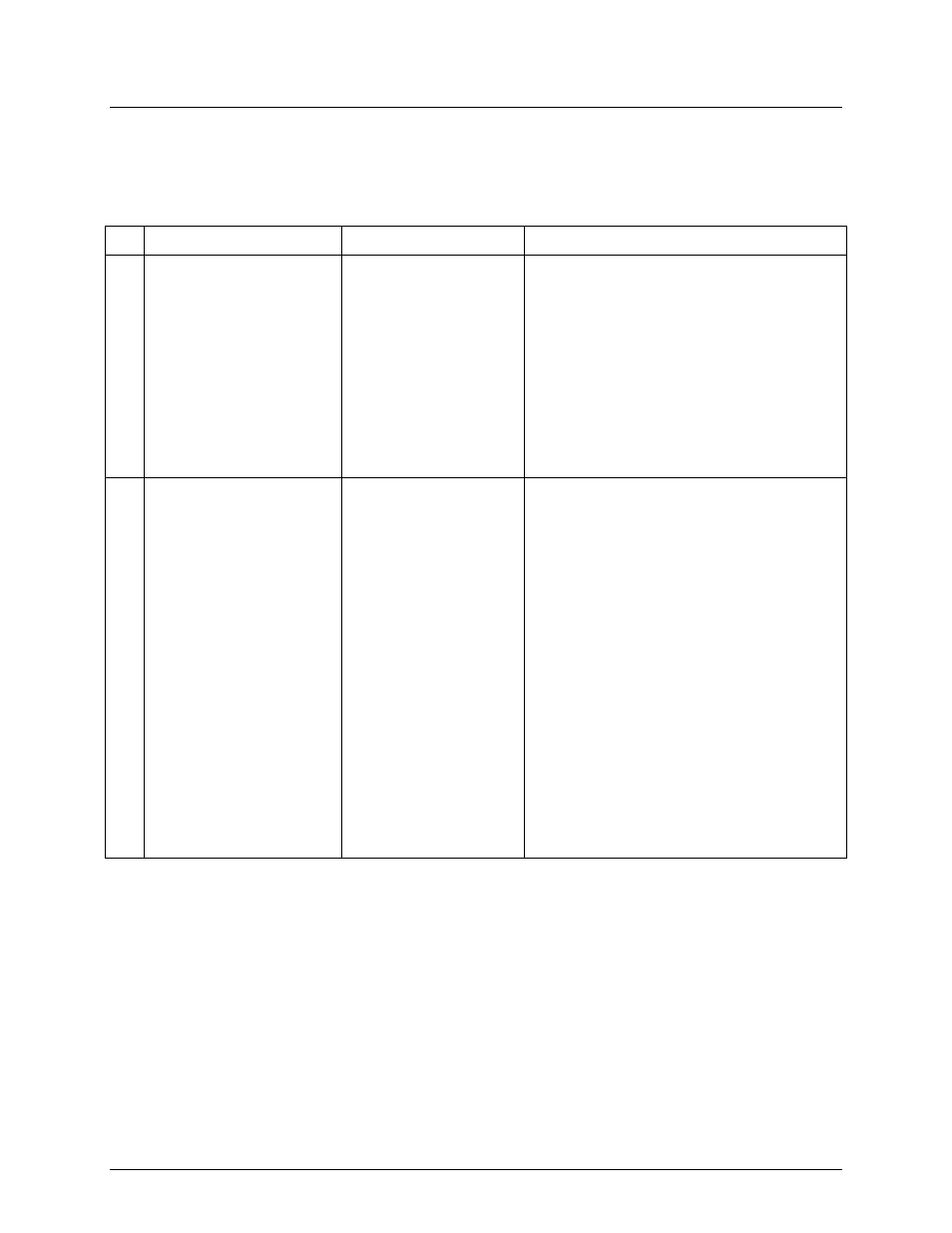

Table 7-1. Troubleshooting – Control Valve MXG-461 and Piping Assembly

No.

Fault Indication

Probable Cause

Corrective Action

T1

System not operating.

Control Valve is closed

and outlet water temp. is

far below setpoint.

1. No power supplied to

Control Valve

2. Control signal not

being supplied from

Temp. Controller.

1. Remove Valve Electronics Module cover

(Figure 4-1) and verify that 24 VAC power

is present at pin 1 of terminal strip.

Restore power if necessary. Proceed to

Table 7-2 and check Over-Temp Switch

and 24 VAC Transformer circuit breaker to

ensure they have not tripped.

2. Verify presence of a 0 to 10 VDC control

signal at pin 5 of terminal strip. If control

signal is not present, troubleshoot

ECS/SP per Table 7-2.

T2

System over-heats by

more than 10°F above the

desired setpoint.

Outlet temp is below

Over-Temp limit setting

1. Control Valve is in

the MANUAL mode.

2. Control Valve not

fully closed.

3. Temp. Controller not

set properly or

defective.

4. Control Valve not

calibrated correctly

5. Heat Exchanger

scaled on DHW side.

1. Ensure Control Valve is set to the AUTO

mode.

2. Check the 0 – 10 VDC control signal

being supplied to Actuator. If signal is

greater than 0 VDC when heater outlet

temperature is 10°F (or more) above the

desired setpoint, proceed to next item in

list.

3. Refer to Chapter 4 – ADJUSTMENTS

and check current setting of Temp.

Controller. Readjust if necessary. If

adjustment does not clear fault, proceed

to Table 7-2 and continue.

4. Refer to Chapter 4, para. 4.2 and auto-

calibrate the valve by pressing the button

(Figure 4-2). If Valve stem does not fully

stroke up and down, contact AERCO for

assistance.

5. Clean and de-scale Heat Exchanger.