AERCO SmartPlate User Manual

Page 49

SmartPlate Installation, Operation & Maintenance Manual

CHAPTER 7 – TROUBLESHOOTING

OMM-0069_0E

AERCO International, Inc.

100 Oritani Dr. Blauvelt, NY 10913

Page 49 of 138

SP-100

Phone: 800-526-0288

PRI: 11/26/2013

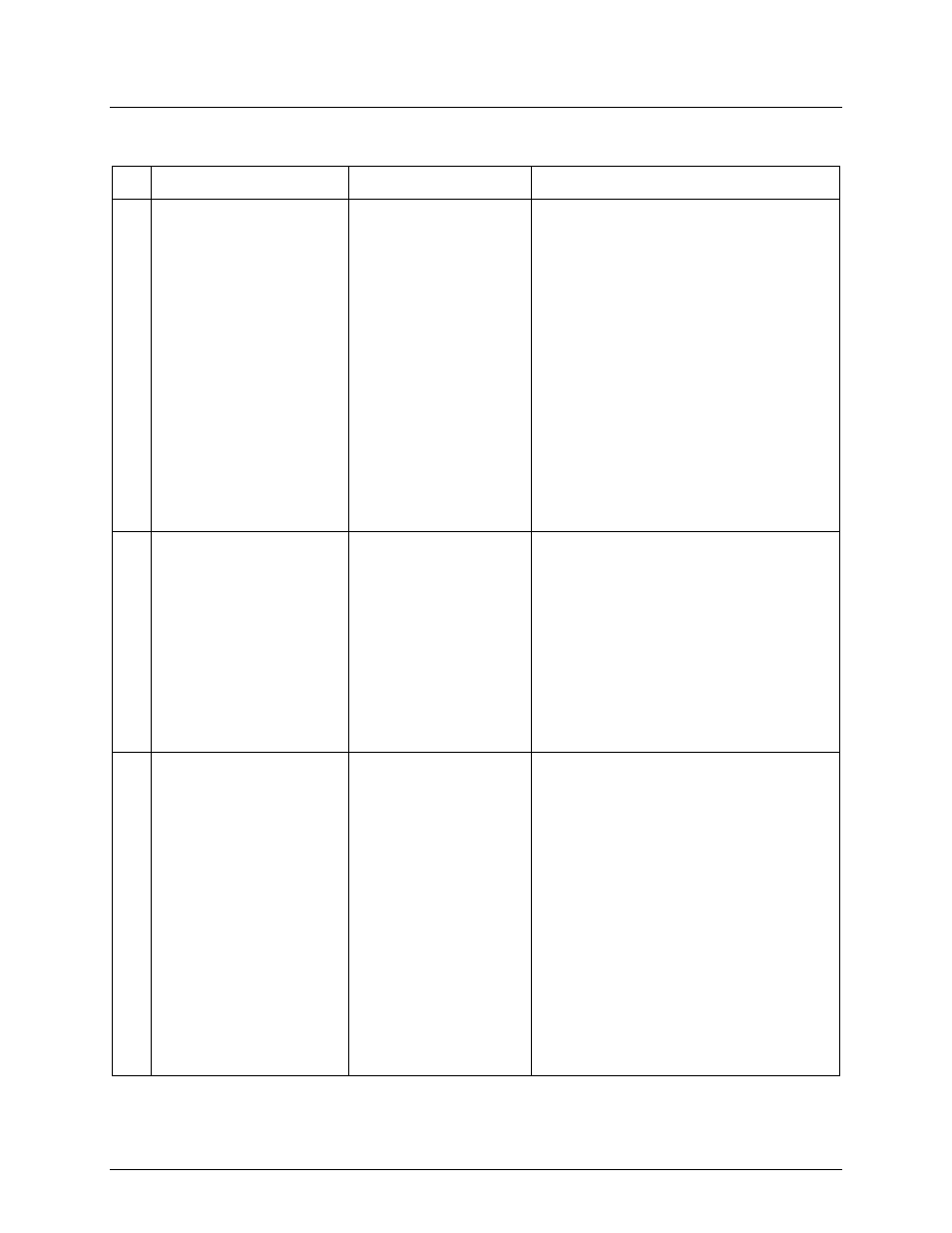

Table 7-1. Troubleshooting – Control Valve MXG-461 and Piping Assembly – Cont.

No.

Fault Indication

Probable Cause

Corrective Action

T3

System outlet water

temperature is below

desired setpoint

1. Boiler water inlet

strainer is clogged

2. Boiler water temp is

too low.

3. Boiler water flow rate

too low.

4. Temp controller is

not properly set.

1. Check the strainer differential pressure

gauge. If gauge is in the “RED” area,

blow down the strainer and re-check

until gauge is in the “GREEN” area.

2. Check the Boiler Water IN temperature

on the Control Box display indicator.

Verify that the temperature is equal to

the boiler water temperature to which

the unit was sized.

3. Check system pump and measure flow

rate to the SmartPlate with an ultra-

sonic meter.

4. Refer to Chapter 4, para. 4.3.1 and

check the current setpoint temperature

setting on the Temp Controller. If the

setting is below the desired setpoint,

readjust as necessary.

T3

(Continued)

5. Control Valve is not

opening properly.

6. Heat Exchanger is

fouled on boiler water

side.

7. Heat Exchanger is

scaled on boiler

water side

8. Heat Exchanger is

too small for load.

5. Remove Electronics module cover on

Valve and view the Status LEDs. See

Table 7-1A to check the Valve status.

6. Proceed as follows:

a. Close isolation valves

b. Clean strainers

7. Clean or de-scale Heat Exchanger.

8. Reduce load or resize Heat Exchanger.

T4

Wide variation in Heater

outlet temperature during

wide variations in flow

1. ECS/SP mixed water

temperature sensor

is not functioning

properly

2. DHW internal

Recirculation Pump

is not functioning

properly

1. Refer to Table 7-2 and check the

operation of the mixed water

temperature sensor.

2. Proceed as follows:

a. Check the fuse on the side of the

ECS Control Box and replace if

blown.

b. Check input power to Recirculation

Pump.

c. Check the temperature of the copper

tube above the Pump. It should be

the

same as the outlet DHW

temperature.

If cold, repair or replace pump as

required.