AERCO SmartPlate User Manual

Page 40

SmartPlate Installation, Operation & Maintenance Manual

CHAPTER 6 – SCHEDULED MAINTENANCE

Page 40 of 138

AERCO International, Inc.

100 Oritani Dr. Blauvelt, NY 10913

OMM-0069_0E

PRI: 11/26/2013

Phone: 800-526-0288

SP-100

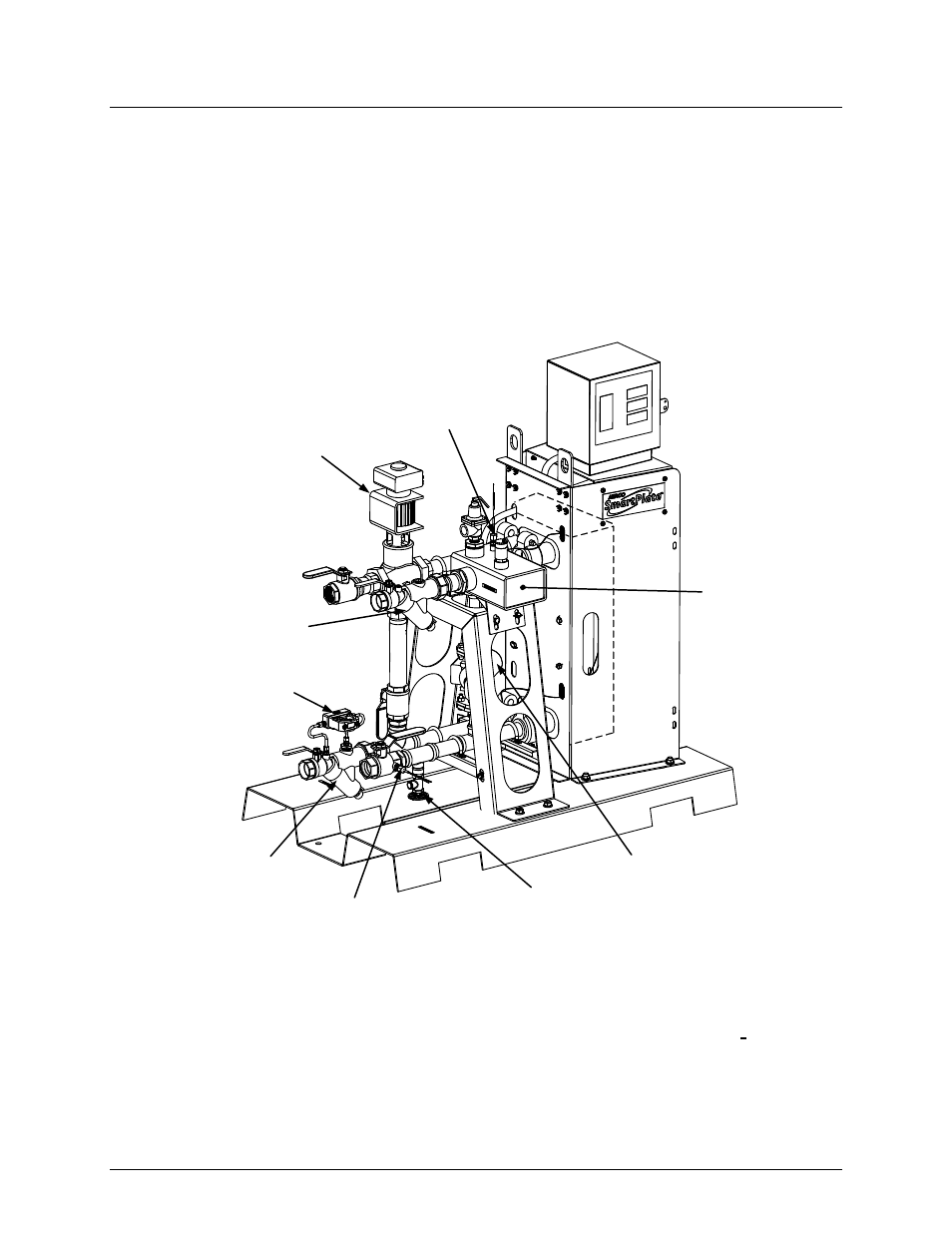

2. Check to ensure that the Gauge reading is in the Green area on the dial.

3. If the Gauge is reading in the Red area of the dial, attach a hose to the blow-down valve

at the base of the Strainer. Cycle the blow-down valve open and closed 6 times.

4. If the Gauge still reads in the Red area on the dial, refer to Chapter 6 – Corrective

Maintenance to repair or replace the Differential Pressure Gauge.

5. If the Gauge reading is in the Green area for 5 consecutive weeks, this maintenance task

can be performed monthly, instead of weekly.

ECS/SP

CONTROL

BOX

CONTROL

VALVE

MXG-461

MANIFOLD

BOILER WATER

DIFFERENTIAL

PRESSURE GAUGE

DRAIN

VALVE

FEED FWD

TEMP SENSOR

RECIRC.

PUMP

DHW

DUAL OUTLET

TEMP SENSOR

BOILER

WATER INLET

STRAINER

DOMESTIC

WATER INLET

STRAINER

Figure 6-1. Location of Components for Scheduled Maintenance

6.3 PLATE PACK LEAKAGE CHECKS (DOUBLE-WALL MODELS ONLY)

For SmartPlate Double-Wall Models, check the Plate Pack for leaks as follows:

1. Remove the splash guard to access the Plate Pack (see Figure 5-1).