Cub Cadet 8454 User Manual

Page 141

TRANSMISSION SYSTEM

4-37

D569-W03 June-2003

•

When assembling, let the oil groove

of the thrust collar faced toward the

gear.

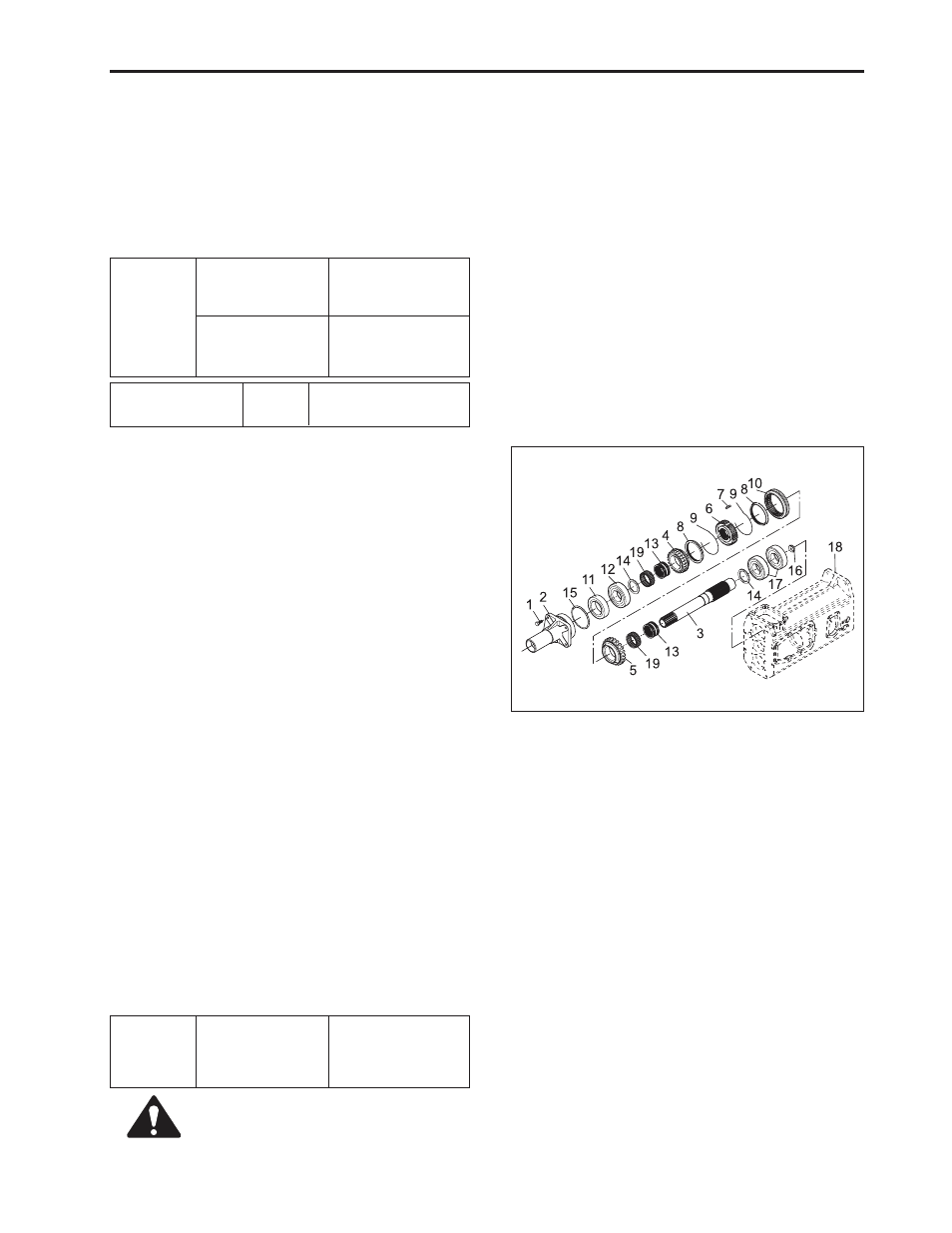

I. SHUTTLE SHAFT SECTION

a . To Disassembling

1. Remove clutch lever, release hub and release fork.

2. Loosen inlet bolt (1) of the propeller shaft case and

remove propeller shaft case (2).

3. Draw out shuttle shaft (3) to the front of the middle

case.

b. To Assemble

1. Install 6008 ball bearing (17) on middle case (18).

2. Install oil seal (16) on the inner bore of shuttle shaft

(3) and apply grease.

3. Sub-assemble synchro hub (6), synchronizer key

(7), spring (9) and shifter (10).

4. Locate shuttle shaft (3) on the assembling area of

middle case (18) and fix inner ring (13), 29 gear (5),

needle bearing (19), synchronizer ring (8) and syn-

chro hub which have been sub-assembled in due

order, and then install shuttle shaft (3) on ball bear-

ing (17) after inserting thrust collar (14).

5. Install needle bearing (19) and inner ring (13) on

the inner bore of 24 gear (4) of the shuttle shaft.

6. Sub-assemble oil seal (19), ball bearing (12) and

O-ring (15) on propeller shaft case (2), and apply

grease.

7. After inserting thrust collar (14) into shuttle shaft

(3), place the sub-assembly of propeller shaft case

(2) in shuttle shaft (3) to tighten 4 washer mounting

bolts (1) on middle case (18).

(1) Bolt

(2) Propeller Bearing Shaft Case

(3) Shuttle Shaft

(4) 29 Gear

(5) 24 Gear

(6) Synchro Hub

(7) Synchronizer Key

(8) Synchronizer Ring

(9) Spring

(10) Shifter

(11) Ball Bearing

(12) Ball Bearing

(13) Inner Ring

(14) Collar

(15) O-Ring

(16) Oil Seal

(17) Ball Bearing

(18) Middle Case

(19) Needle Bearing

Tightening

torque

Inlet bolt of the

propeller shaft

case

23.5 ~ 27.5 N·m

2.4 ~ 2.8 kgf·m

17.3 ~ 20.2 lbf·ft

Tightening

torque

Tightening bolt of

the bearing case

Tightening bolt of

the auxiliary shift

cover

77.5 ~ 90.2 N·m

7.9 ~ 9.2 kgf·m

57.1 ~ 66.5 lbf·ft

48.0 ~ 55.9 N·m

4.9 ~ 5.7 kgf·m

35.4 ~ 41.2 lbf·ft

• Auxiliary shift

Factory

spec.

• 15.994 ~ 15.976 mm

(0.629 ~ 0.628 in.)

569W454A

CAUTION

10. Locate fork rod (for Hi-Lo shift) (27) and shift fork (for

Hi-Lo shift) (26) at right position.

11. After pushing the sub-assembled of bearing case

(22) forward from the back of the middle case to be

aligned with the position of parallel pin (21), knock

in and fix it with four with washer bolts (23).

12. Insert steel ball (32) and stopper spring (33) into

the hole area of middle case for main shift cover

assembling.