Rockwell Automation Flex/WebPak 3000 DC Drive ControlNet, Network Communication Board, 915FK2101 User Manual

Page 26

4-4

ControlNet Network Communication Option Board For Use With FlexPak 3000 and WebPak 3000 DC Drives

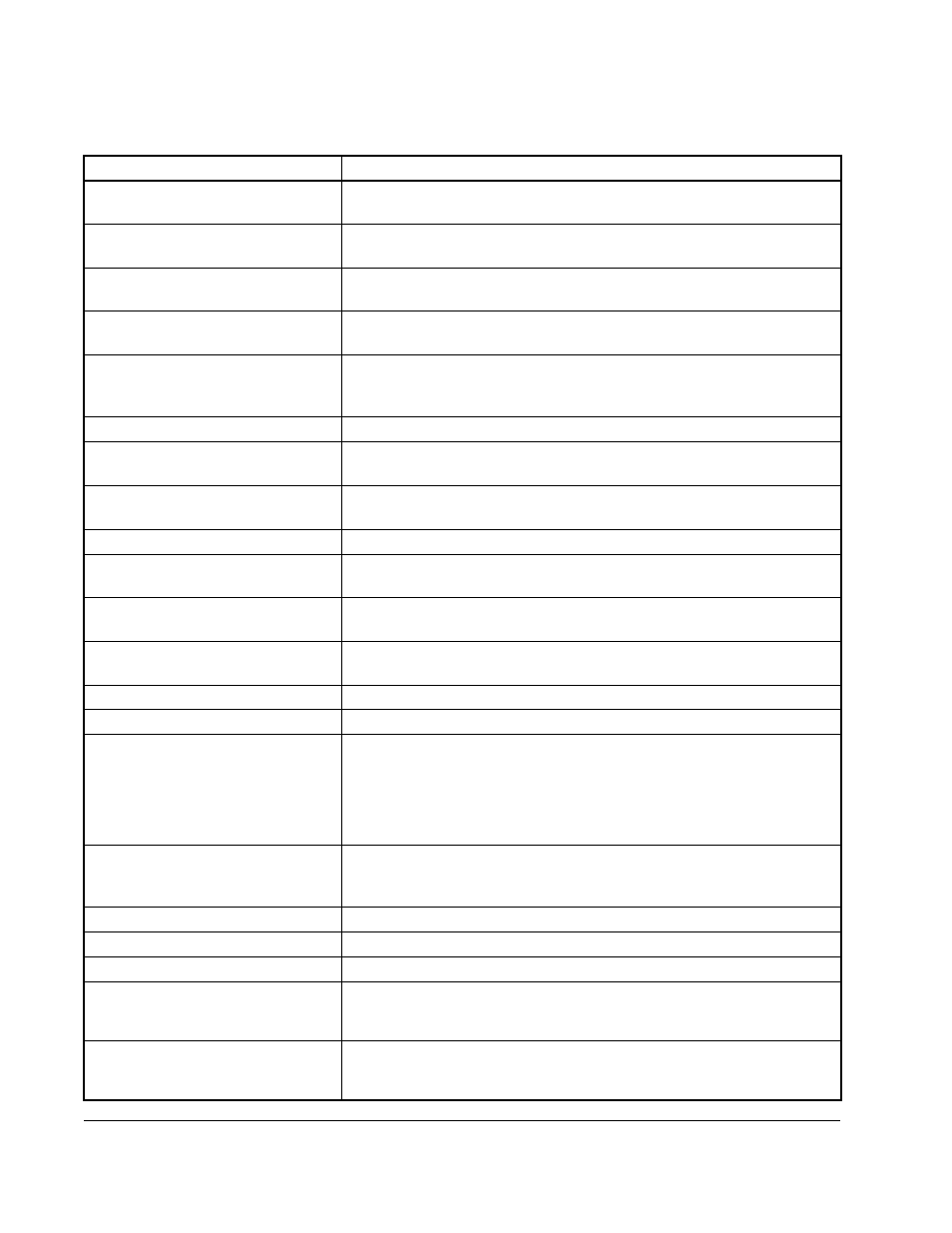

Table 4.4 – FlexPak 3000 Scheduled Drive Reference Data

Name

Description (PLC to Drive)

Word 0 Drive Control Word

This word consists of a set of bits written to by the PLC to control the

state of the drive (only when

CONTROL

SOURCE

SELECT

=

NETWORK

).

Bit 00 Run

Starts the drive in run mode. A 0-to-1 transition causes the drive to

start (if ready). Setting this bit to zero (0) does not stop the drive.

Bit 01 Stop

A value of 0 stops the drive. A value of 1 allows the drive to become

ready.

Bit 02 Fault Reset

Resets (only) the latched fault on a 0-to-1 transition. This bit does not

affect the contents of the fault log.

Bit 03 Jog/Stop

Starts the drive in jog mode. A 0-to-1 transition causes the drive to

start (if ready). Setting this bit to zero (0) causes the drive to stop (only

after jog time-out or if no run command is asserted).

Bit 04 Forward/Reverse

Operating direction command: Forward (0) or reverse (1).

Bit 05 Overwind/Underwind

Selects the direction in winder applications; overwind (0) or underwind

(1).

Bit 06 Speed Loop PI Reset

Selects the operational state of the Speed Loop PI block; normal (0) or

reset (1).

Bit 07 OCL Enable

Disables/holds in reset (0) or enables (1) the Outer Control Loop.

Bit 08 Fault Log Clear, Reset

Clears the fault log contents on a 0-to-1 transition and resets the

latched fault.

Bit 09 Alarm Log Clear, Reset

Clears the alarm log contents on a 0-to-1 transition and resets the

alarm indicator.

Bit 10 Alarm Reset

Resets (only) the alarm on a 0-to-1 transition. This bit does not affect

the alarm log.

Bit 11 Memory Save

Performs a memory save operation in the drive on a 0-to-1 transition.

Bit 12 - 15 Reserved

Reserved

Word 1 Speed/Torque Reference

This word is written to by the ControlNet network to command a speed

or torque reference. When the drive is configured as a speed

regulator, a value of 4095 corresponds to

TOP

SPEED

(P.011). When

the drive is configured as a torque/current regulator, a value of 4095

corresponds to

MAXIMUM

CURRENT

(P.007) percent of

MOTOR

RATED

ARM

AMPS

(P.008).

Word 2 Field Reference

This word is written to by the ControlNet network to command a field

reference value. 1= 1/4095 of

MOTOR

HOT

FLD

AMPS

(P.510). This

value is only used by the drive if a field current regulator kit is installed.

Word 3 Network Input 1

A value that is input in various places of the speed loop.

Word 4 Network Input 2

A value that is input in various places of the speed loop.

Word 5 Network Input 3

A value that is input in various places of the speed loop.

Word 6 Speed Feedback Gain

Value (1000 = 1.000) multiplied by speed feedback (range 1000 to

32000. Used in simple winder applications for roll diameter

compensation.

Word 7 Speed Loop PI Initial

Value

Initial value of speed loop PI block when

CONTROL

SOURCE

SELECT

(P.000) =

NETWORK

and Spd Loop PI Reset (bit 06, Drive Control

Word) = 1. Range -32768 to 32767.