Rockwell Automation Flex/WebPak 3000 DC Drive ControlNet, Network Communication Board, 915FK2101 User Manual

Page 25

Programming the Drive

4-3

4.2.2 Programming Scheduled Drive Reference Data

Setting

CONTROL

SOURCE

SELECT

to

NETWORK

allows the scheduled data from the PLC

to control the drive. If

CONTROL

SOURCE

SELECT

≠

NETWORK

, then scheduled drive

reference data from the ControlNet network is not used.

The scheduled drive reference data can be configured as one to eight words of data.

The first word of the scheduled drive reference data is always the drive control word; it

is written in element 0 of the Output file. Should you configure less than eight words of

output data, you can access the Scheduled Drive Reference Data through file N12

(see section 4.3) as unscheduled data messages.

You must create a drive control application program to run in the programmable

controller. This application program must write from one to eight words of data to the

file you defined during drive configuration as the Output Address. The value you

defined as the Output Size determines how many words of data the option board can

accept from the programmable controller. During a scheduled data transfer, the

programmable controller writes the data contained in the Output Address to the option

board.

Reference and control information is scanned by the drive at different rates depending

on the type of data and the drive operating mode (speed regulator or voltage

regulator). If the drive is configured as a speed regulator, all of the reference inputs

are evaluated every 5 ms for FlexPak 3000 drives, every 10 ms for WebPak 3000

drives. If the drive is configured as a voltage regulator, all of the reference inputs are

scanned every 10 ms. The drive control bits are always evaluated every 20 ms.

Table 4.4 describes the function of each word of the FlexPak 3000 scheduled drive

reference data. Table 4.5 describes the function of each word of the WebPak 3000

scheduled drive reference data.

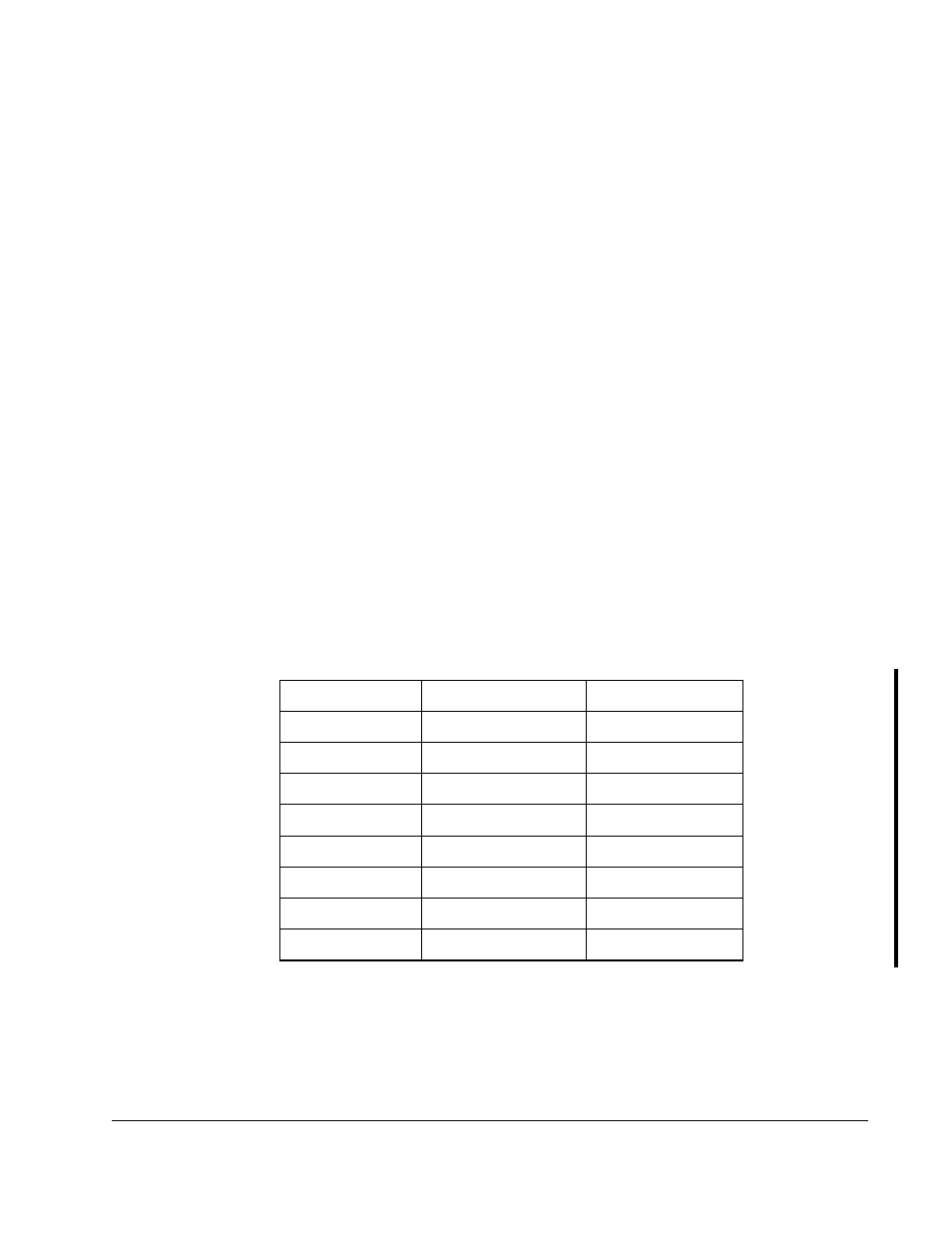

Table 4.3 – Data Sent/Received 8 Words (Maximum)

PLC to Drive

FlexPak

WebPak

Word 0

Control

Control

Word 1

Reference

Reference

Word 2

Reference

Network 1

Word 3

Network 1

Network 2

Word 4

Network 2

Network 3

Word 5

Network 3

Field Reference

Word 6

Speed FB. Gain

Not Used

Word 7

Speed Loop PI

Not Used