Base voltage, Base frequency, Maximum voltage – Rockwell Automation 1336Z SPIDER - FRN 2.xxx-5.xxx User Manual

Page 130: Run/accel volts, Sync loss sel, Motor sync loss detection for synchronous motors

7–58

Programming

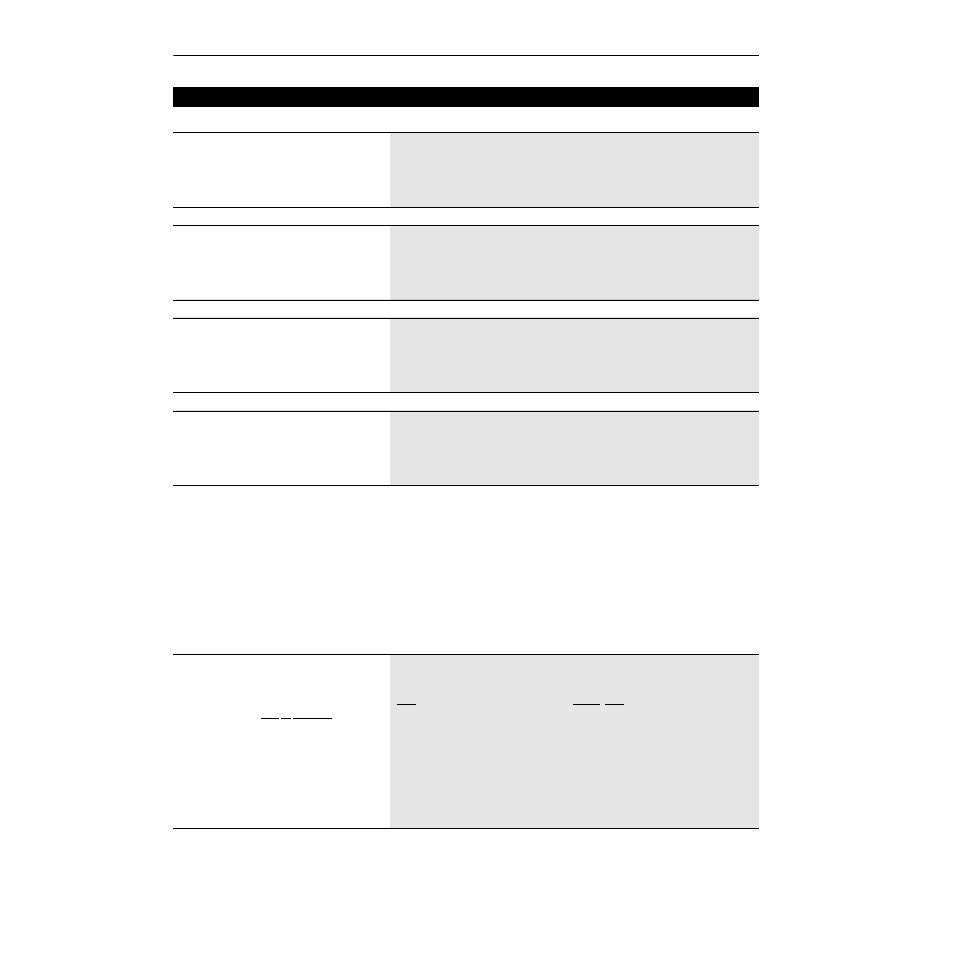

[Base Voltage]

This value should be set to the motor nameplate rated

voltage.

Parameter Number

18

Parameter Type

Read and Write

Display Units / Drive Units

1 Volt / 4096 = Drive Rtd Volts

Factory Default

Drive Rated Volts

Minimum Value

25% of Drive Rated Voltage

Maximum Value

120% of Drive Rated Voltage

[Base Frequency]

This value should be set to the motor nameplate rated

frequency.

Parameter Number

17

Parameter Type

Read and Write

Display Units / Drive Units

1 Hertz / Hertz x 10

Factory Default

60 Hz

Minimum Value

25 Hz

Maximum Value

400 Hz

[Maximum Voltage]

This parameter sets the highest voltage the drive will

output for “Fixed Boost” & “Full Custom.”

Parameter Number

20

Parameter Type

Read and Write

Display Units / Drive Units

1 Volt / 4096 = Drive Rtd Volts

Factory Default

Drive Rated Volts

Minimum Value

25% of Drive Rated Voltage

Maximum Value

120% of Drive Rated Voltage

[Run/Accel Volts]

In “Fixed Boost” or “Full Custom” modes, the output voltage

is reduced by the programmed amount while at frequency.

Parameter Number

317

Parameter Type

Read and Write

Display Units / Drive Units

1% / 4096 = 100%

Factory Default

100%

Minimum Value

50%

Maximum Value

100%

[Sync Loss Sel]

This parameter allows selection of various sync loss

modes.

Important: The motor must be connected to the drive

when the sync loss function is enabled.

Parameter Number

310

Parameter Type

Read and Write

Factory Default

“Disabled”

Units

Display Drive

“Disabled” 0

sync loss detection and recovery

function is disabled

“Alarm” 1

sync loss detection and recovery

function is enabled

“Fault” 2

sync loss detection and recovery

function is enabled. If the sync loss

continues for longer than the time

set by [Sync Loss Time], the drive

faults with a F67 “Motor Sync Loss”

fault indication.

Motor Sync Loss Detection for

Synchronous Motors

This function is enabled if [Sync Loss Sel] is set to “Alarm” or “Fault”.

The motor sync loss detection attempts to sense when a synchronous motor has pulled out of sync. When

this happens the motor will typically draw a high current and the power flow between the motor and the

drive oscillates. Based on this, the detection algorithm looks for a large oscillation of the current (relative

to voltage) angle while the current is high. When loss of sync is detected, the “Sync Loss” bit in [Drive

Alarm 1] is set. Additionally, the drive will add an additional voltage set by [Sync Loss Comp] to the output

voltage. This will increase the pull-in torque to allow the motor to re-synchronize.

If [Sync Loss Sel] is set to “Fault,” the time the “Sync Loss” bit is set is timed. If it exceeds the time set by

[Sync Loss Time], the drive faults with a F67 “Motor Sync Loss” fault indication.