Pid reference and feedback – Rockwell Automation 284E ArmorStart with EtherNet/IP - User Manual User Manual

Page 329

Rockwell Automation Publication 280E-UM001B-EN-P – July 2012

329

PID Setup Appendix D

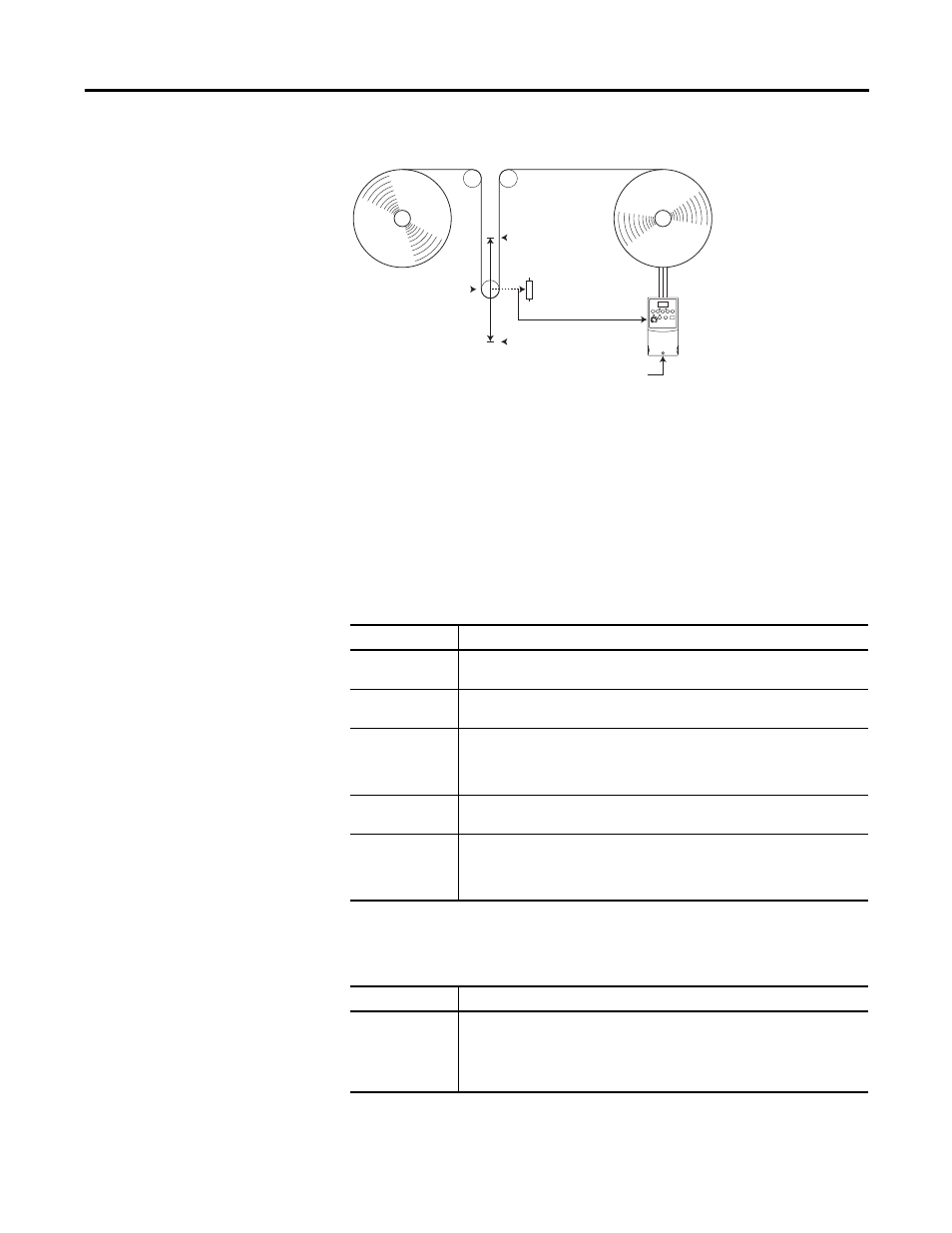

PID Reference and Feedback

Parameter 232 (PID Ref Sel) is used to enable/disable the PID mode. Select

Option 0 (PID Disabled) to disable or Option 1 to select the source of the PID

Reference. If Parameter 232 (PID Ref Sel) is not set to 0 (PID Disabled), the PID

can still be disabled by selecting the programmable Digital Input options

(Parameters 151…154) such as Jog, Local, or PID Disable.

Parameter 233 (PID Feedback Sel) is used to select the source of the PID

feedback.

Options

Description

0

PID Disabled

Disables the PID loop (default setting)

1

PID Setpoint

Selects Exclusive Control. Parameter 237 (PID Setpoint) will be used to set the value of the PID

Reference

4

Comm Port

Selects Exclusive Control. The reference word from a communication network DeviceNet

™

becomes the PID Reference. The value sent over the network is scaled so that Parameter 135

(Maximum Freq) x 10 = 100% reference. For example, with (Maximum Freq) = 60 Hz, a value

of 600 sent over the network would represent 100% reference.

5

Setpnt, Trim

Selects Trim Control. Parameter 237 (PID Setpoint) will be used to set the value of the PID

Reference.

8

Comm, Trim

Selects Trim Control. The reference word from a communication network DeviceNet becomes

the PID Reference. The value sent over the network is scaled so that Parameter 135

(Maximum Freq) x 10 = 100% reference. For example, with (Maximum Freq) = 60 Hz, a value

of 600 sent over the network would represent 100% reference.

Option

Description

2

Comm Port

The Consumed Assembly (Instance 164 – Default Consumed Inverter Type Distributed Motor

Controller) from a communication network

which becomes the PID Feedback. The value sent

over the network is scaled so that Parameter 135 (Maximum Freq) x 10 = 100% Feedback. For

example, with (Maximum Freq) = 60 Hz, a value of 600 sent over the network would

represent 100% Feedback.

Speed Reference

0 Volts

PID Feedback =

Dancer Pot Signal

10 Volts

PID Reference =

Equilibrium Set Point