Typical multiple drive connection examples, Installation/wiring 1-27 – Rockwell Automation 22C PowerFlex 400 AC Drive FRN 1.xx - 7.xx User Manual

Page 39

Installation/Wiring

1-27

PowerFlex 400 Adjustable Frequency AC Drive FRN 1.xx - 7.xx User Manual

Publication 22C-UM001I-EN-P

Typical Multiple Drive Connection Examples

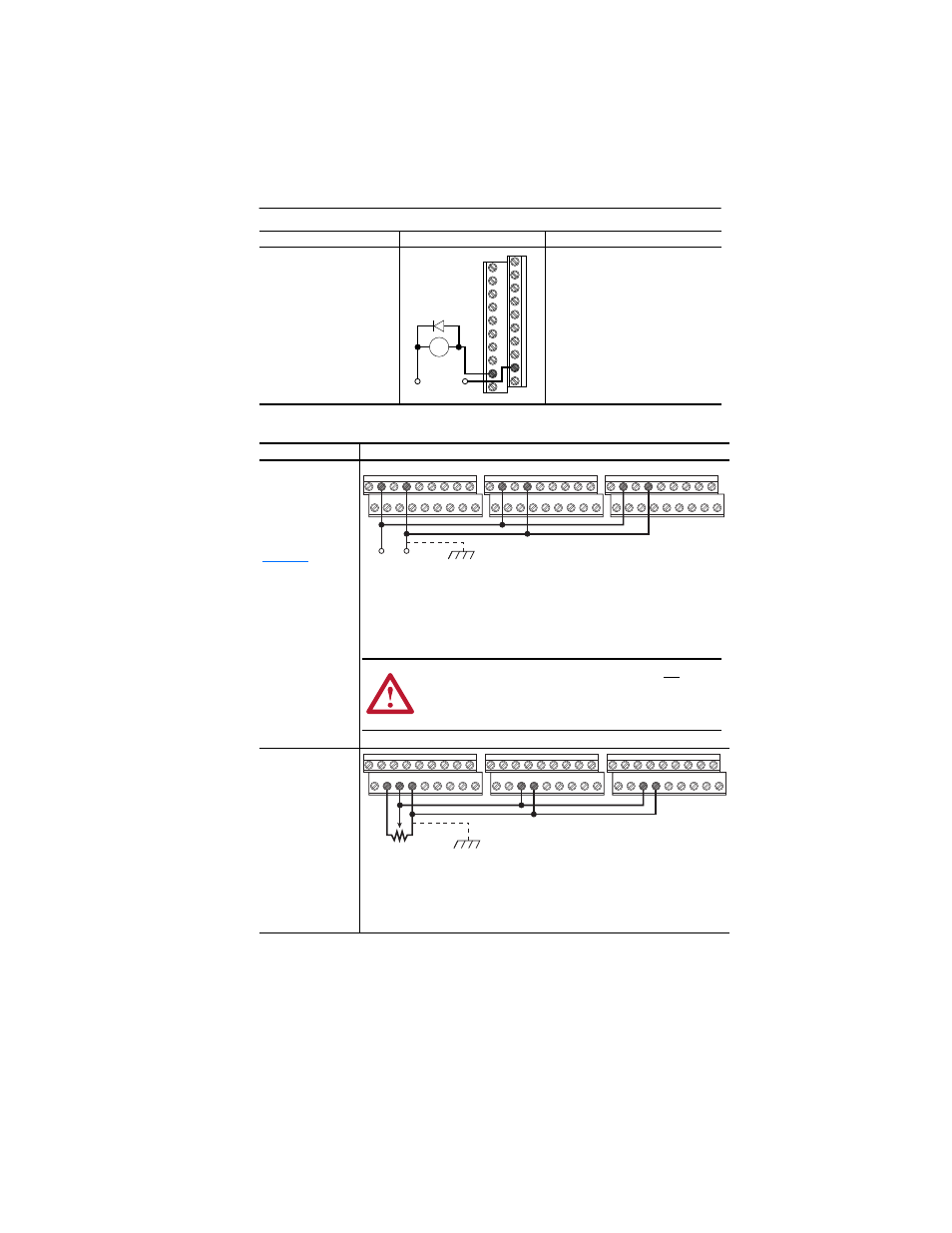

Opto Output

•

When using Opto Output with

an inductive load such as a

relay, install a recovery diode

parallel to the relay as shown

to prevent damage to the

output.

•

Opto Output is rated 30V DC,

50 mA (non-inductive).

Parameters

T065 [Opto Out Sel] = 0 through 15

T066 [Opto Out Level]

T068 [Opto Out Logic]

Input/Output

Connection Example

Required Settings

Common

+24V

CR

09

19

Input/Output

Connection Example

Multiple Digital

Input Connections

Customer Inputs can

be wired per the

External Supply

(SRC) example on

When connecting a single input such as Run, Stop, Reverse or Preset Speeds to

multiple drives, it is important to connect I/O Terminal 04 common together for all

drives. If they are to be tied into another common (such as earth ground or

separate apparatus ground) only one point of the daisy chain of I/O Terminal 04

should be connected.

Multiple Analog

Connections

When connecting a single potentiometer to multiple drives it is important to

connect I/O Terminal 14 common together for all drives. I/O Terminal 14 common

and I/O Terminal 13 (potentiometer wiper) should be daisy-chained to each drive.

All drives must be powered up for the analog signal to be read correctly.

Customer Inputs

Optional Ground Connection

04

02

04

02

04

02

ATTENTION: Digital inputs on multiple drives should not be tied

together when using SNK (Internal Supply) mode. In SNK mode, if

power is removed from one drive, inadvertent operation of other

drives that share the same I/O Common connection may occur.

Remote Potentiometer

Optional Ground Connection

12

13 14

13 14

13 14