Pid reference and feedback – Rockwell Automation 22C PowerFlex 400 AC Drive FRN 1.xx - 7.xx User Manual

Page 181

Application Notes

D-5

PowerFlex 400 Adjustable Frequency AC Drive FRN 1.xx - 7.xx User Manual

Publication 22C-UM001I-EN-P

PID Reference and Feedback

Parameter

[PID Ref Sel] is used to enable the PID mode (A152 = 0

“PID Disabled”) and to select the source of the PID Reference. If A152

[PID Ref Sel] is not set to 0 “PID Disabled”, PID can still be disabled by

select programmable digital input options (parameters

-

) such

as “Local” or “PID Disable”.

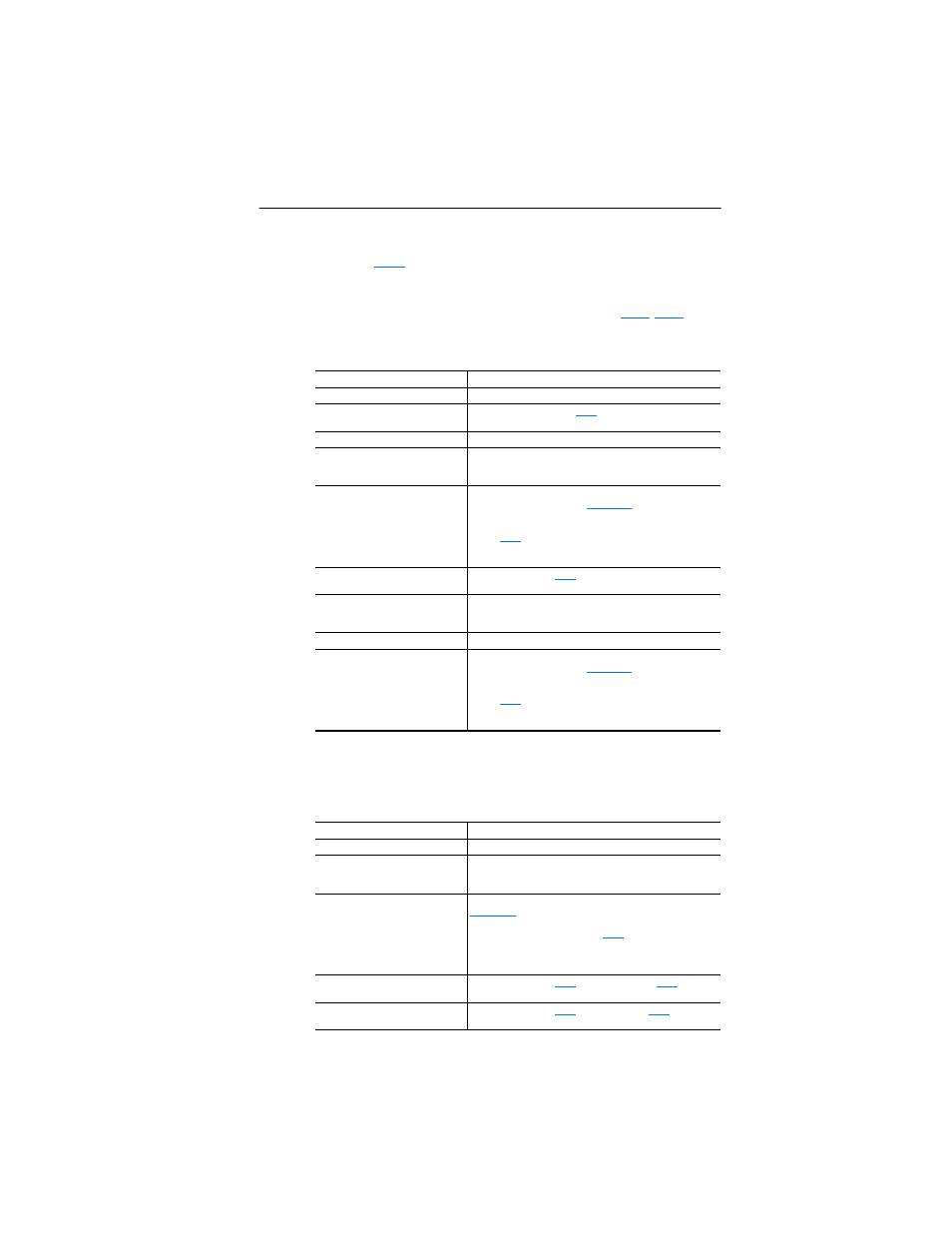

Table D.A A152 [PID Ref Sel] Options

A153 [PID Feedback Sel] is used to select the source of the PID

feedback.

Table D.B A153 [PID Feedback Sel] Options

Option

Description

0 “PID Disabled”

Disables the PID loop (default setting)

1 “PID Setpoint“

Selects Exclusive Control.

[PID Setpoint] will be used to

set the value of the PID Reference

2 “Analog In 1”

Selects Exclusive Control. Selects the Analog In 1 Input.

3 “Analog In 2”

Selects Exclusive Control. Selects the Analog In 2 Input. Note

that the PID will not function with a bipolar analog input. It will

ignore any negative voltages and treat them like a zero.

4 “Comm Port”

Selects Exclusive Control. The reference word from a

communication network (see

for details on the

reference word) such as Modbus RTU or DeviceNet becomes

the PID Reference. The value sent over the network is scaled

so that

[Maximum Freq] x 10 = 100% reference. For

example, with [Maximum Freq] = 60 Hz, a value of 600 sent

over the network would represent 100% reference.

5 “Setpnt, Trim”

[PID Setpoint] will be used to set

the value of the PID Reference.

6 “0-10V, Trim”

Selects Trim Control. Selects the 0-10V Input. Note that the

PID will not function with a bipolar analog input. It will ignore

any negative voltages and treat them like a zero.

7 “4-20mA, Trim”

Selects Trim Control. Selects the 4-20mA Input.

8 “Comm, Trim”

Selects Trim Control. The reference word from a

communication network (see

for details on the

reference word) such as Modbus RTU or DeviceNet becomes

the PID Reference. The value sent over the network is scaled

so that

[Maximum Freq] x 10 = 100% reference. For

example, with [Maximum Freq] = 60 Hz, a value of 600 sent

over the network would represent 100% reference.

Option

Description

0 “Analog In 1”

Selects the Analog In 1 Input (default setting).

1 “Analog In 2“

Selects the Analog In 2 Input. Note that the PID will not

function with a bipolar analog input. It will ignore any negative

voltages and treat them like a zero.

2 “Comm Port”

The reference word from a communication network (see

for details on the reference word) such as Modbus

RTU or DeviceNet becomes the PID Feedback. The value sent

over the network is scaled so that

[Maximum Freq] x 10 =

100% Feedback. For example, with [Maximum Freq] = 60 Hz, a

value of 600 sent over the network would represent 100%

Feedback.

3 “ACT1 - ACT2”

Selects actual inputs

[ACT1 Input] minus

[ACT2

Input] to be used as the feedback signal.

4 “ACT1 + ACT2”

Selects actual inputs

[ACT1 Input] plus

[ACT2

Input] to be used as the feedback signal.