Model-, suffix- and option-codes, Integral type rcct3, model- and suffix- code, Integral type rcct3, option- code – Yokogawa RotaMASS 3-Series User Manual

Page 69

8. GENErAL SPECIFICATIONS

8-15

IM 01R04B05-00E-E 3rd edition July 30, 2010 -00

all Rights Reserved. Copyright © 2005, Rota Yokogawa

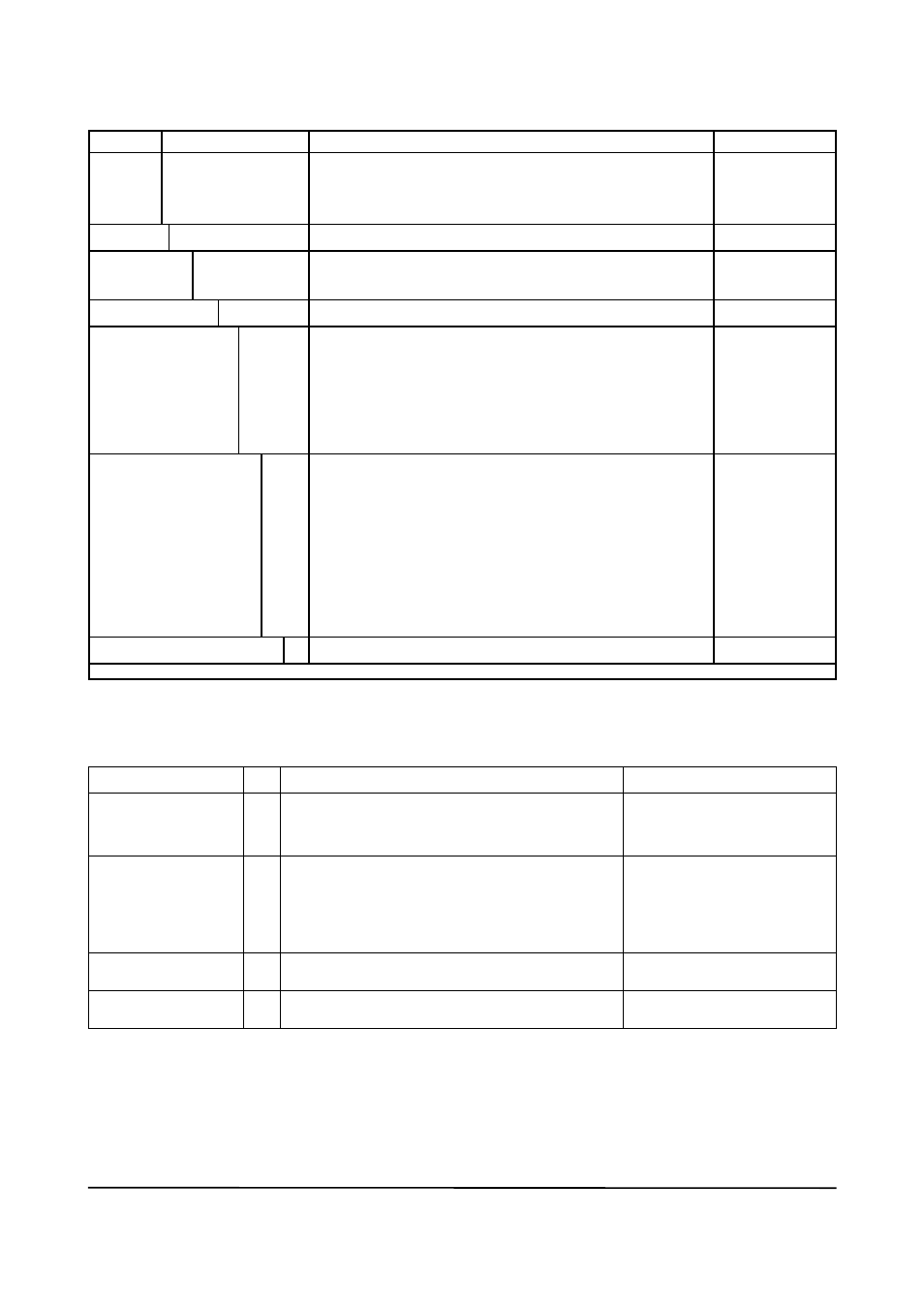

MOdEL-, SUFFIX- ANd OPTION-COdES

Integral type rCCT3, Model- and Suffix- Code :

Model

Suffix Code

description

restrictions

RCCt34

RCCt36

RCCt38

RCCt39

RCCt39/IR

RCCt39/XR

nominal Value : 2.7 t/h = 45 kg/min

nominal Value : 10 t/h = 170 kg/min

nominal Value : 32 t/h = 533 kg/min

nominal Value : 100 t/h = 1670 kg/min

nominal Value : 250 t/h = 4170 kg/min

nominal Value : 500 t/h = 8340 kg/min

only with /HP

Power supply

-a

-D

90 - 264 V aC

24 V DC

Indicator direction

H1

H2

V0

n0

Detector installation horizontal, tubes down

Detector installation horizontal, tubes up

Detector installation vertical

Without indicator

recom. for liquid service

recom. for gas service /Ga

Cable conduit connection

M

a

M20 x 1, female thread with cable glands

anSI ½´´ nPt, female thread without cable glands

mandatory with /FF3

Process connection size

1)

23

01

02

04

05

06

08

10

12

15

20

¾´´

Dn 15, ½´´

Dn 25, 1´´

Dn 40, 1½´´

Dn 50, 2´´

Dn 65, 2½´´

Dn 80, 3´´

Dn 100, 4´´

Dn 125, 5´´

Dn 150, 6´´

Dn 200, 8´´

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

Process connection rating and style

1)

a1

a2

a3

a4

a5

D2

D4

D5

D6

J1

J2

S2

S4

S8

G9

t9

aSME flange class 150, process connection dim. + facing acc. aSME B16.5

aSME flange class 300, process connection dim. + facing acc. aSME B16.5

aSME flange class 600, process connection dim. + facing acc. aSME B16.5

aSME flange class 900, process connection dim. + facing acc. aSME B16.5

aSME flange class 1500, process connection dim. + facing acc. aSME B16.5

En flange Pn 16, process connection dim. + facing acc. En 1092-1 Form B2

En flange Pn 40, process connection dim. + facing acc. En 1092-1 Form B2

En flange Pn 63, process connection dim. + facing acc. En 1092-1 Form B2

En flange Pn 100, process connection dim. + facing acc. En 1092-1 Form B2

JIS flange 10K, JIS B 2220

JIS flange 20K, JIS B 2220

thread acc. DIn 11851

Clamp, process connection dimensions acc. DIn 32676

Clamp, process connection dim. acc. tri-Clover (tri-Clamp) and ½´´ Mini Clamp

G, female thread

nPt, female thread

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

see table 11

Material of wetted parts

1)

SL

HC

Stainless steel 316L (1.4404)

Hastelloy C-22 (2.4602)

only RCCt34 to 39/IR

1)

see selection table „Process connection and materials“ (table 11)

Integral type rCCT3, Option- Code :

Options

Option

code

description

restrictions

Fieldbus Communication

/FB

/LC1

/EE

/Bt3

Digital communication (Foundation Fieldbus protocol)

Provides a PID control function block

Provides software download capability

With customer specified tag number of FF- communication + node address in

converter

max. 32 digits software tag + node address ;

not with /PS

Hazardous area approvals

/KF3

/KF4

/FF3

/EF3

/EF4

/uF3

/uF4

atEX Flame proof converter + Intrinsic safe detector

atEX Flame proof converter + Intrinsic safe detector + Intrinsic safe fieldbus

FM approval for uSa + Canada, Flame proof converter + Intrinsic safe detector

IECEx Flame proof converter + Intrinsic safe detector

IECEx Flame proof converter + Intrinsic safe detector + Intrinsic safe fieldbus

InMEtRo Flame proof converter + Intrinsic safe detector

InMEtRo Flame proof converter + Intrinsic safe detector + Intrinsic safe fieldbus

with /HP for gas group IIB

with /HP for gas group IIB

only with cable conduit “a”; with /HP not for

groups a and B

with /HP for gas group IIB

with /HP for gas group IIB

with /HP for gas group IIB

with /HP for gas group IIB

GoSt approval

/QR1

/QR2

/QR3

Russian GoSt approval

Kazakh GoSt approval

uzbekistan GoSt approval

see page 8

see page 8; not for RCCt39/XR; not with /HP

see page 8; not for RCCt39/XR; not with /HP

Dual Seal approval

/DS

/RD

Dual Seal approval (conform with anSI/ISa-12.27.01)

Rupture disk

only with /FF3; not with process connection a5;

not wit RCCt39/XR, preferable with /Ga,

mandatory if /DS+/Ga is selected