4 setting of tags and addresses – Yokogawa RotaMASS 3-Series User Manual

Page 27

5. CONFIGUrATION

5-3

IM 01R04B05-00E-E 3rd edition July 30 2010 -00

all Rights Reserved. Copyright © 2005, Rota Yokogawa

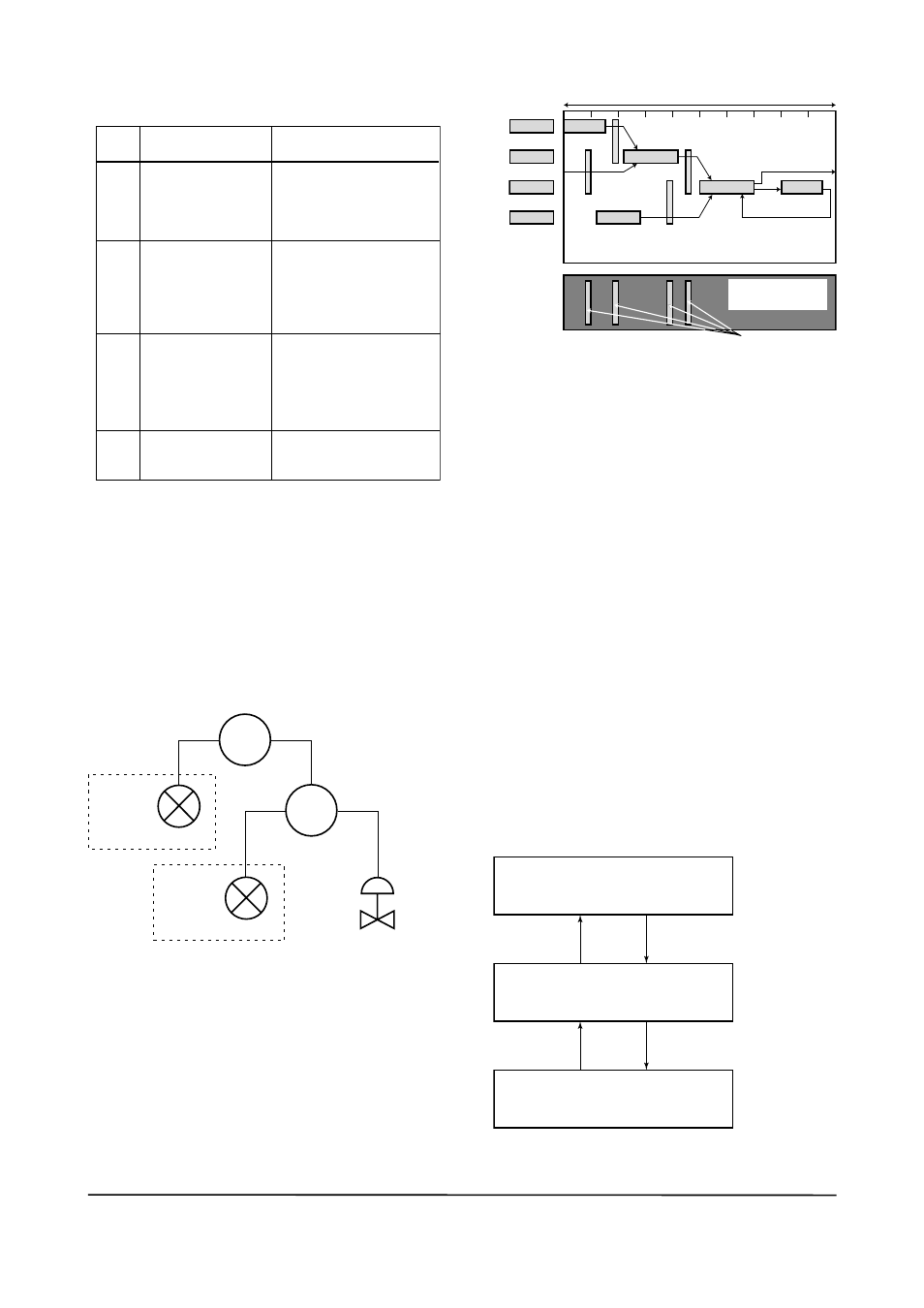

Table 5.3 Function Block Execution Schedule

of rOTAMASS

t0503.EPS

Index

Parameters

Setting (Factory Setting in

Parentheses)

269

(SM)

MaCRoCYCLE_DuRatIon Repetition period of control

or measurement, i.e.,

macrocycle; to be set as a

multiple of 1/32 ms (32000 =

1 second)

276

(SM)

FB_StaRt_EntRY.1 Start time of the aI1 block

represented as the elapsed

time from the start of each

macrocycle; to be set as a

multiple of 1/32 ms (0 = 0

ms)

277

(SM)

FB_StaRt_EntRY.2 Start time of the PID block

(optional) represented as

the elapsed time from the

start of each macrocycle; to

be set as a multiple of 1/32

ms (9600 = 300 ms)

278 (SM)

to

289 (SM)

FB_StaRt_EntRY.3 to

FB_StaRt_EntRY.14

not set.

a maximum of 30 ms is taken for execution

of each aI block. arrange the communication

schedule for an aI block’s data that is to be trans-

ferred to its downstream block in such a way that

it starts after a lapse of longer than 30 ms.

Figure 5.3 shows typical function block and com-

munication schedules for the loop shown in Figure

5.2.

F0502.EPS

FIC100

FIC200

FC100

FI200

ROTAMASS

#2

FI100

ROTAMASS

#1

Figure 5.2 Example of Loop Connecting Func-

tion Blocks of two rOTAMASS with other

devices

FI103

FI100

FC100

FIC100

FC200

FIC200

FC100

FI200

FI200

Function

Block

Schedule

Commu-

nication

Schedule

OUT

IN

OUT

CAS_IN

BKCAL_OUT

BKCAL_IN

BKCAL_IN

BKCAL_OUT

IN

Unscheduled

Communication

Scheduled

Communication

F0503.EPS

Macrocycle (Control Period)

Figure 5.3 Function Block Schedule and

Communication Schedule

When the control period (macro cycle) is set to

more than 4 seconds, set the following interval to

be more than 1% of the control period.

- Interval between “end of block execution” and

“start of sending CD from LaS”

- Interval between “end of block execution” and

“start of the next block execution”

5.4 Setting of Tags and

Addresses

this section describes the steps in the proce-

dure to set the PD tags and node address in the

RotaMaSS. there are three states of Fieldbus

devices as shown in Figure 5.4, and if the state is

other than the lowest SM_oPERatIonaL state,

no function block is executed. Whenever you have

changed the PD tag or address of a RotaMaSS,

transfer its state to SM_oPERatIonaL.

unInItIaLIZED

(no tag nor address is set)

tag clear

tag setting

InItIaLIZED

(only tag is set)

SM_oPERatIonaL

(tag and address are retained, and

the function block can be executed.)

address clear

F0504.EPS

address setting

Figure 5.4 Status Transition by Setting Pd

Tag and Node Address