A2.2 setting and change of basic parameters, A2.3 setting the ai func- tion blocks – Yokogawa RotaMASS 3-Series User Manual

Page 128

APPENdIX 2. APPLICATION, SETTING ANd CHANGE OF BASIC PArAMETErS

a-28

IM 01R04B05-00E-E 3rd edition July 30, 2010 -00

all Rights Reserved. Copyright © 2005, Rota Yokogawa

A2.2 Setting and Change

of Basic Parameters

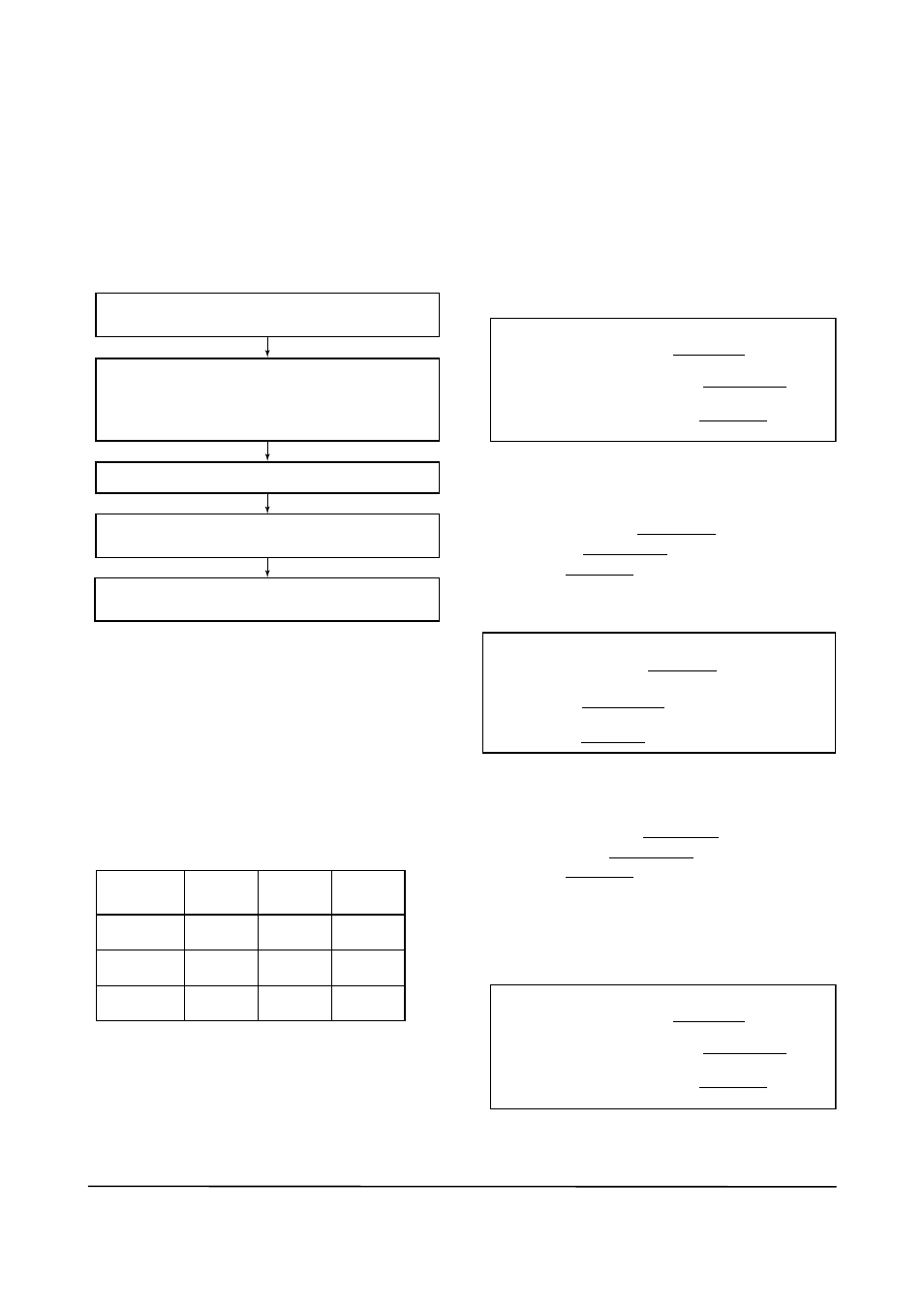

this section describes the procedure taken to set

and change the parameters for each block. ob-

taining access to each parameter differs depend-

ing on the configuration system used. For details,

refer to the instruction manual for each configura-

tion system.

access the parameter to be set or changed.

Make setting or change in accordance with

each parameter.

Set the target of block mode (MoDE_BLK)

back to auto

(*note 2)

.

access the block mode (MoDE_BLK) of each

block.

Fa0201.EPS

Set the target

(*note 1)

of block mode

(MoDE_BLK) to auto, Man or o/S

(*note 2)

according to the Write Mode of the parameter

to be set or changed.

note 1: Block mode consists of the following four modes that

are controlled by the universal parameter that displays

the running condition of each block.

target: Sets the operating condition of the block.

actual: Indicates the current operating condition.

Permit: Indicates the operating condition that the block

is allowed to take.

normal: Indicates the operating condition that the block

will usually take.

note 2: the followings are the operating conditions which the

individual blocks will take.

TA0202.EPS

Automatic

(Auto)

Manual (Man)

AI Function

Blocks

Transducer

Block

Resource

Block

Out of Service

(O/S)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

note: Refer to appendix 1, “List of parameters for each block

of RotaMaSS” for details of the Write Mode for each block.

A2.3 Setting the AI Func-

tion Blocks

Each RotaMaSS contains six aI function blocks

(aI1 to aI6) having independent parameters.Set

up the parameters of each aI block you use, indi-

vidually as necessary.

The AI1 block performs the mass flow rate

output calculation.

(1)-1. Setting the calibration range

FA0202.EPS

Access the XD_SCALE parameter.

Set the required unit in Unit Index of

XD_SCALE.

Set the upper range limit in EU at 100% of

XD_SCALE.

Set the lower range limit in EU at 0% of

XD_SCALE.

Example:

to measure 0 to 100t/h,

Set t/h (1328)*

1

in units Index of XD_SCaLE,

Set 100 in Eu at 100% of XD_SCaLE, and

Set 0 in Eu at 0% of XD_SCaLE.

(1)-2. Setting the output scale

FA0203.EPS

Access the OUT_SCALE parameter.

Set the required unit in Unit Index of OUT_SCALE.

Set the output value corresponding to the upper

range limit in EU at 100% of OUT_SCALE.

Set the output value corresponding to the lower

range limit in EU at 0% of OUT_SCALE.

Example:

to set the output range to 0.00 to 100000.00kg/h,

Set kg/h( 1324)*

1

in units Index of out_SCaLE,

Set 100000 in Eu at 100% of out_SCaLE,

Set 0 in Eu at 0% of out_SCaLE.

The AI2 block performs the volume flow out-

put calculation.

(2)-1. Setting the calibration range

FA0202.EPS

Access the XD_SCALE parameter.

Set the required unit in Unit Index of

XD_SCALE.

Set the upper range limit in EU at 100% of

XD_SCALE.

Set the lower range limit in EU at 0% of

XD_SCALE.