3 standard type, 1 explanation of i/o signals – IAI America PCON-CY User Manual

Page 65

55

5. Operation Using I/O Signals

5.3 Standard

Type

This type assumes situations where the system must achieve high productivity or uses push-motion operation. Use this type if

your application meets the following conditions:

[1] Use the zone output signal to quicken the operation timings with respect to the respective equipment and thereby

reduce the tact time.

[2] Use the zone output signal as an interlock signal to prevent contact with peripheral equipment.

[3] When missed work must be detected in push-motion operation, use the zone output signal as a “simple yardstick” to

determine if the work has been contacted properly or missed.

Caution:

The controller is shipped with the proximity switch type pre-selected. If you want to use the standard type, set

the value of Parameter No. 25 (PIO pattern selection) to “1.”

→ Refer to Chapter 6, “Parameter Settings”

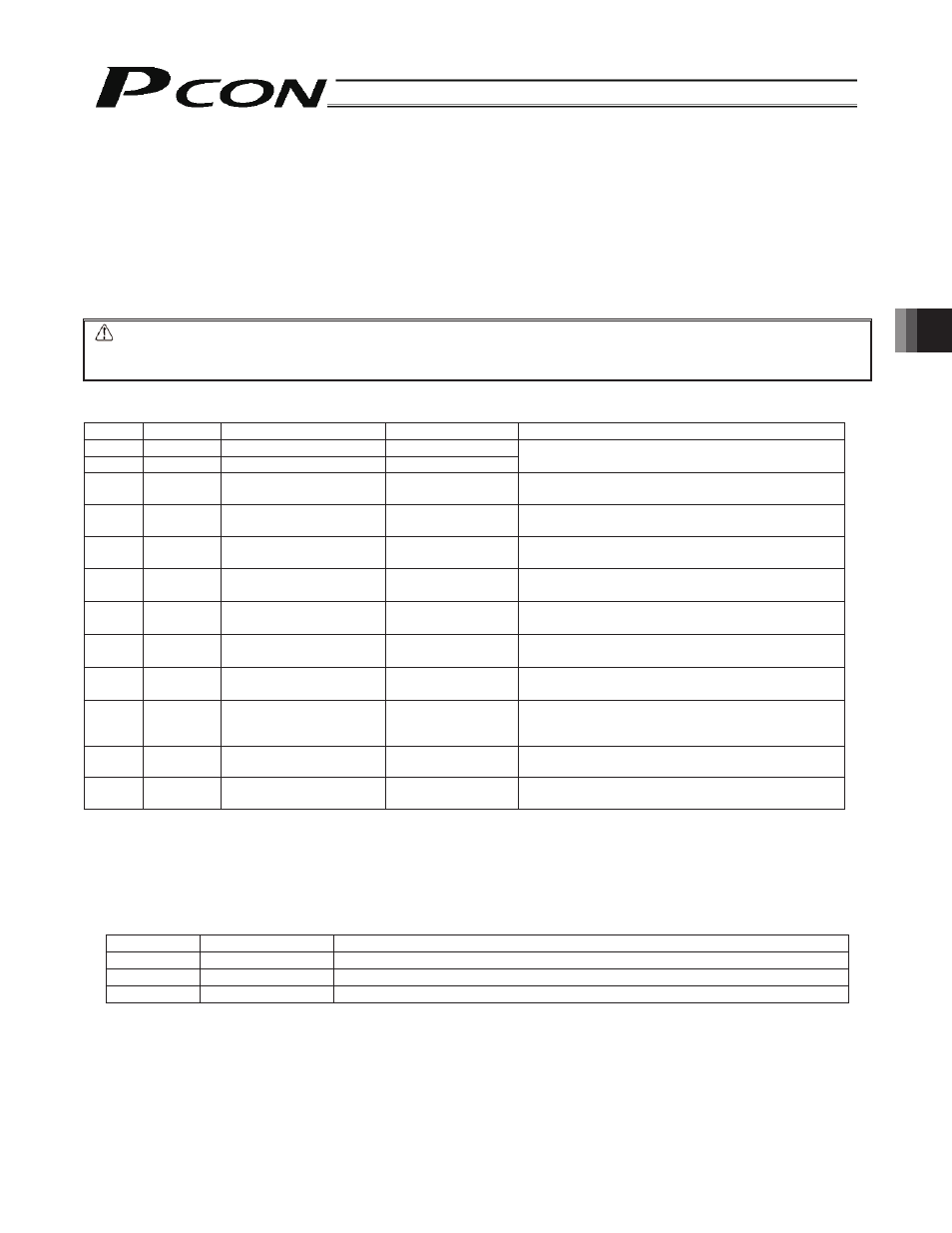

5.3.1

Explanation of I/O Signals

Pin No. Wire color

Signal name

Signal abbreviation

Function overview

1

Brown 1

+24 V

P24V

2

Red 1

0 V

N

I/O power supply

3 Orange

1

Rear end move

command input

ST0

Move command to the rear end

4 Yellow

1

Front end move

command input

ST1

Move command to the front end

5 Green

1

Intermediate point move

command input

ST2

Move command to the intermediate point

6

Blue 1

Servo-on command input SON

The servo remains on while this signal is ON.

The servo remains off while this signal is OFF.

7 Purple

1

Rear end positioning

complete output

PE0

This signal turns ON upon completion of movement

to the rear end.

8 Gray

1

Front end positioning

complete output

PE1

This signal turns ON upon completion of movement

to the front end.

9 White

1

Intermediate point

positioning complete output

PE2

This signal turns ON upon completion of movement

to the intermediate point.

10 Black

1

Zone output

PZONE

This signal remains ON while the actuator is inside the

range set in the “Zone +” and “Zone –” fields of the

position table.

11

Brown 2

Homing complete output HEND

This signal is OFF immediately after the power is

turned on, and turns ON once homing is completed.

12

Red 2

Alarm output

*ALM

This signal remains ON while the actuator is

normal, and turns OFF if an alarm has occurred.

Move Command Input for Each Position (ST0, ST1, ST2)

Since the number of positioning points is limited to three, you can use these inputs just like when controlling an air cylinder.

While each signal remains ON, the actuator moves to the target position.

If the signal turns OFF before the movement is completed, the actuator will decelerate to a stop.

Before executing each move command, enter a target position as an absolute coordinate in the “Position” field under one

of Nos. 0 to 2 in the position table.

Input signal

Target position

Remarks

ST0

Rear end

The target position is defined in the “Position” field under Position No. 0.

ST1

Front end

The target position is defined in the “Position” field under Position No. 1.

ST2

Intermediate point The target position is defined in the “Position” field under Position No. 2.

Servo-on Command Input (SON)

The servo remains on while this signal is ON.

To ensure safety, it is recommended that the PLC be configured to monitor the condition of the entire system and turn ON

this signal once all conditions required for movement are satisfied.