IAI America PCON-CY User Manual

Page 56

46

5. Operation Using I/O Signals

z Normal Operating Procedure

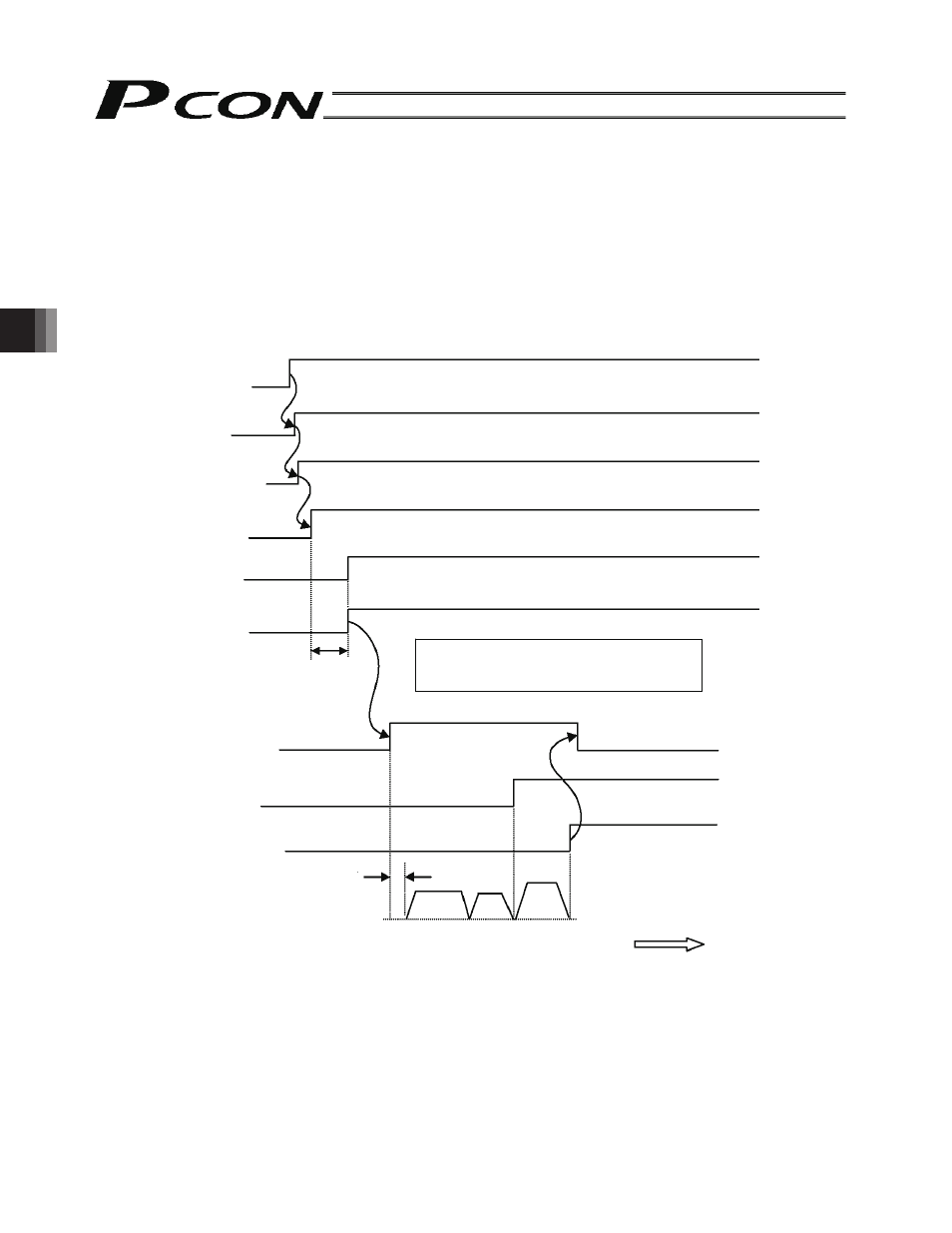

The operating procedure in a normal condition is explained below.

[1] Confirm that the slider or rod is not contacting a mechanical end or that the work is not contacting any peripheral

equipment.

[2] Cancel the emergency stop or connect the motor drive power.

[3] Supply the 24-VDC I/O power.

[4] Supply the 24-VDC controller power.

[5] Input a servo-on signal from the PLC (if the servo-on input is enabled).

[6] First, input a rear end move command signal from the PLC (to cause the actuator to stand by at the rear end).

[7] Start automatic operation.

(Note 1) : Excited-pole detection time = 0.2 to 12 sec

Normally the detection of excited pole completes in approx. 0.2 sec, although the exact time varies from one

actuator to another due to individual differences and also depending on the load condition. If the detection of

excited pole has failed, the excited-pole detection operation will be continued for up to 12 sec.

Safety circuit status

Supply of 24-VDC

I/O power

Supply of 24-VDC

controller power

Servo-on input

(SON)

SV lamp

(front panel)

Ready output (SV)

Emergency stop cancelled

Green

T

1

(Note 1)

Input a move command after the SV has

turned ON. (If a move command is input

when the SV is OFF, the command will be

Rear end move

command input (ST0)

Homing complete

output (HEND)

Rear end detection

output (LS0)

Power-

on pos

ition

Mechanical end

Home position

Rear end

Start of continuous

operation

Max. 6 msec