FEC MICRO NR User Manual

Page 70

Chapter 7: System Operations

Page 7-2

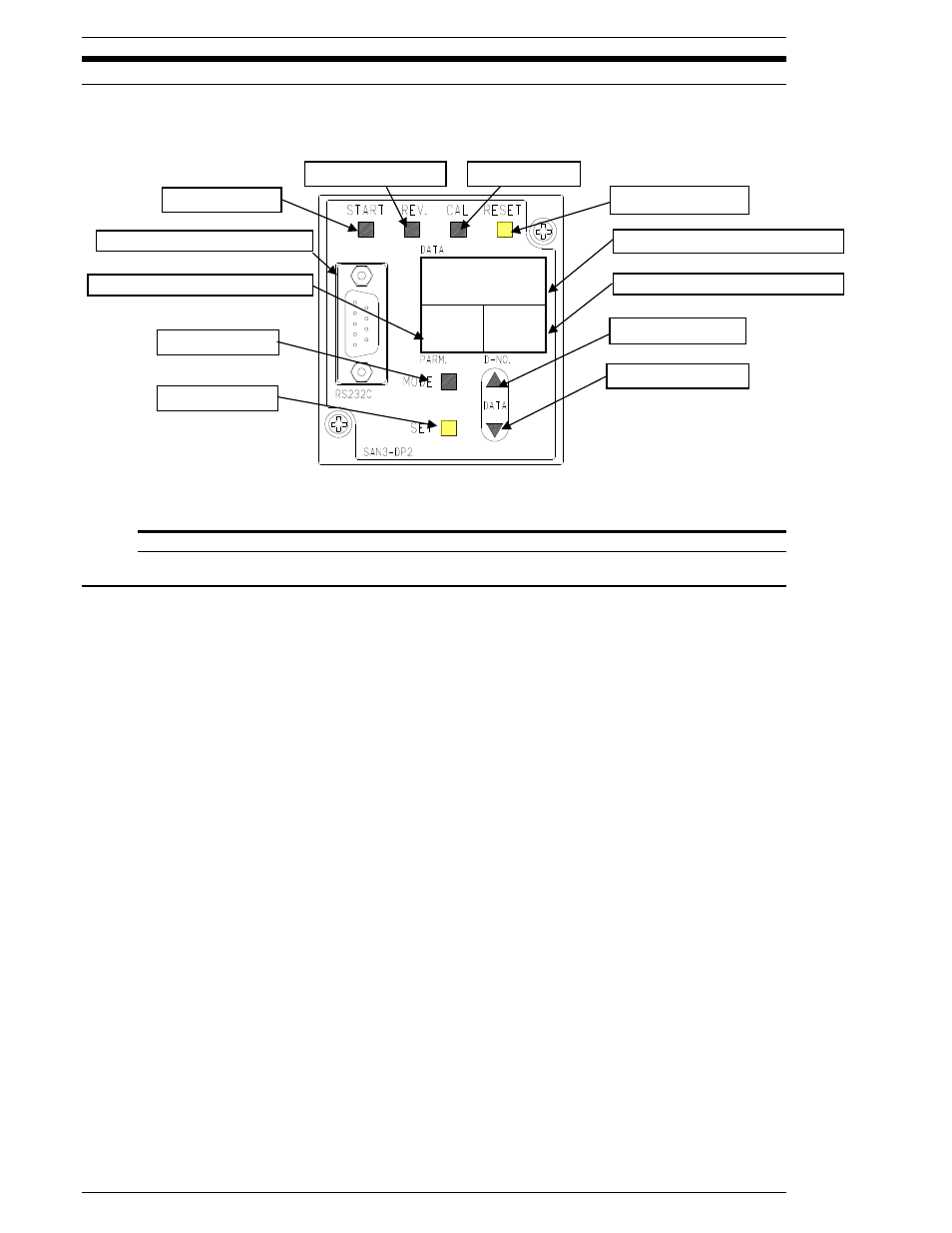

7.1 MNR Display and Programming operation.

FIG. 7-1 Operational controls and indicators

7.1.1 Manual Fastening controls for Display Programming Unit.

wSTART

This push button initiates the fastening cycle. If the unit

’s start mode is set to AUTO, a pulse

of 200~500 ms activates the cycle. If the start mode is set to DEADMAN, the signal has to be

active until the fastening ends, otherwise the cycle will be aborted.

wREV (Manual Reverse)

While this push button is depressed, the micro-nutrunner rotates in the opposite direction of

the programmed fastening direction

for the Parameter selected via the PLC “Work Select”

inputs.

wCAL (Calibration).

Transducer Calibration Check push button. Depress this push-button to obtain the CAL

voltage level from the tool pre-amplifier. This level is compared to the data stored in memory.

If the difference is within the allowed range the ACCEPT LED will light, otherwise the

REJECT LED will light. The calibration voltage level is converted to the full-scale torque,

according to the parameter setting and is shown in the "DATA" display.

wRESET

Used to reset the MNR unit. If this push button is pressed during fastening, the process will

stop and all the fastening data and output signals will be reset. At the same time, the Zero

level of the torque transducer will be checked. If it is within the acceptable range the ACCEPT

LED will light. If it is not within range the REJECT LED will light.

START Button

RESET Button

MODE Button

SET Button

DATA ↑Button

チ

DATA ↓Button

REVERSE Button

CAL Button

DATA display (4digit)

D-NO display (2digit)

PARM display (2digit)

RS-232C Connecter