FEC MICRO NR User Manual

Page 60

Chapter 6: Fastening Instructions

Page 6-4

6.1.2 Torque / Angle Method - Target Angle Control.

Fastening is performed based upon attaining a desired Angle value,

while monitoring the Torque of

the fastener and time.

Additional monitor items (limits) can be set to enhance the system’s ability to

determine if the fastener was properly secured (Section 6.2).

{

{

{

{

Fastening explanation

1. After start signal command the system runs INITIAL SPEED until INITIAL TIME expires.

2. Once FREERUN REVOLUTIONS or FREERUN TIME expire, the speed will switch from

FREERUN SPEED to SLOWDOWN SPEED.

3. Once SPEED CHANGE TORQUE is reached the speed runs at TORQUE SPEED to

fasten to STANDARD ANGLE. STANDARD ANGLE must be reached within the

FASTENING TIME LIMIT or a reject will occur.

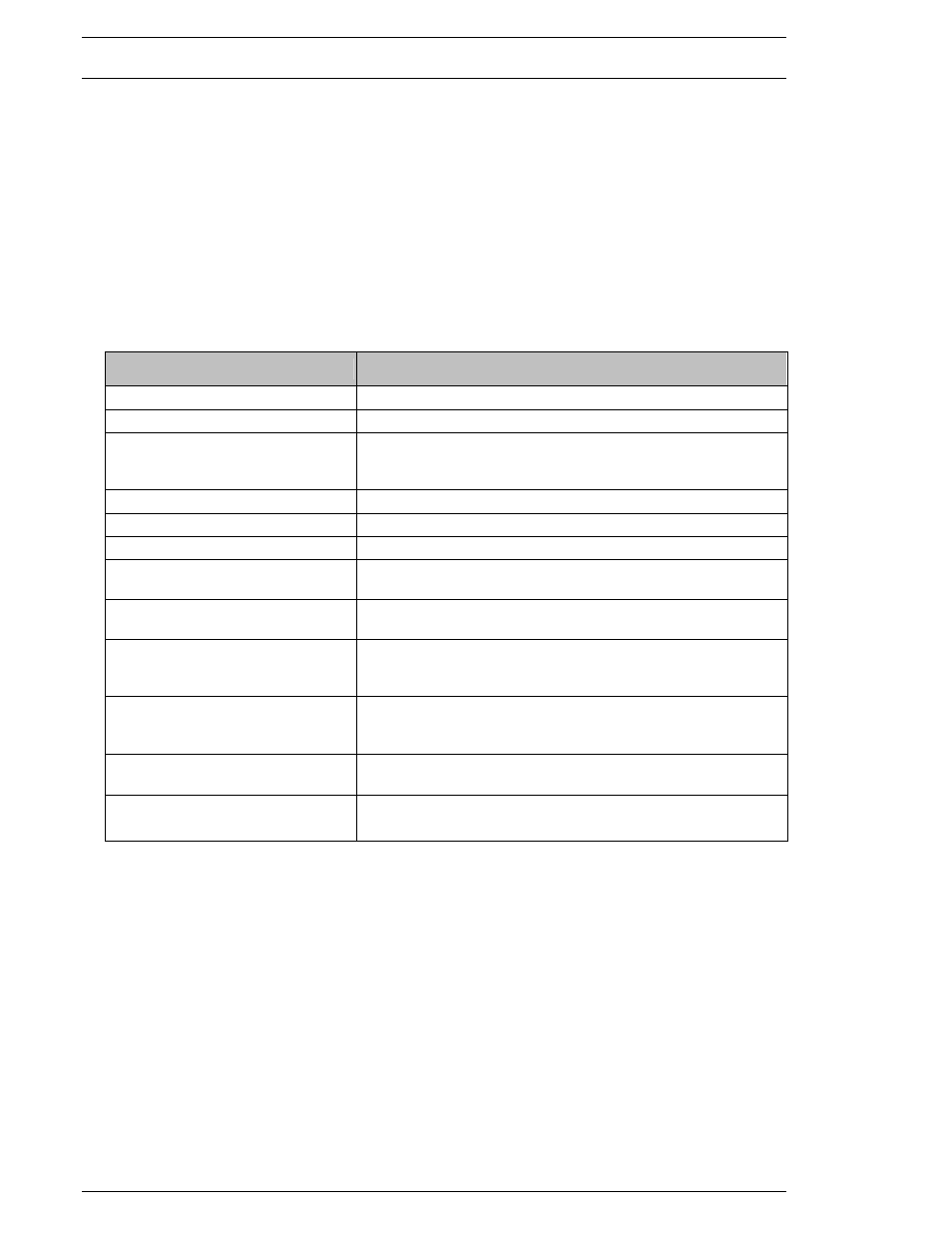

FUNCTION

RECOMMENDATION / COMMENT

14: SPEED CHANGE TORQUE

10% of STANDARD TORQUE

16: SNUG TORQUE

Angle Control Start Point (section 6.2)

13: STANDARD TORQUE

Set at Calibration Torque or high enough as not to

inadvertently stop the cycle and judge the operation based

upon this value.

22: STANDARD ANGLE

Engineered product fastening specification (ANGLE)

42: FASTENING TIME LIMIT

Acceptance range to go from Cycle start to end of cycle.

11: PEAK TORQUE HIGH LIMIT

This is the high torque limit for the fastening cycle. If this limit

is exceeded the system will display reject.

12: PEAK TORQUE LOW LIMIT

This is the low torque limit for the fastening cycle. If this limit

is not achieved the system will display reject.

20: ANGLE LOW LIMIT

This is the low angle limit for the fastening cycle. If this limit is

not achieved the system will display reject. The snug torque

value is used for starting the angle count.

21: ANGLE HIGH LIMIT

This is the high angle limit for the fastening cycle. If this limit

is exceeded the system will display reject. The snug torque

value is used for starting the angle count.

68: RUNDOWN REVOLUTION

LOW LIMIT

Numeric value that represents the minimum number of revo-

lutions during fastening cycle.

69: RUNDOWN REVOLUTION

HIGH LIMIT

Numeric value that represents the maximum number of revo-

lutions during fastening cycle.