3 torque inhibit – FEC MICRO NR User Manual

Page 67

FEC Micro Nutrunner Operations Manual

Chapter 6: Fastening Instructions (Rev. 2: 02/12)

Page 6-11

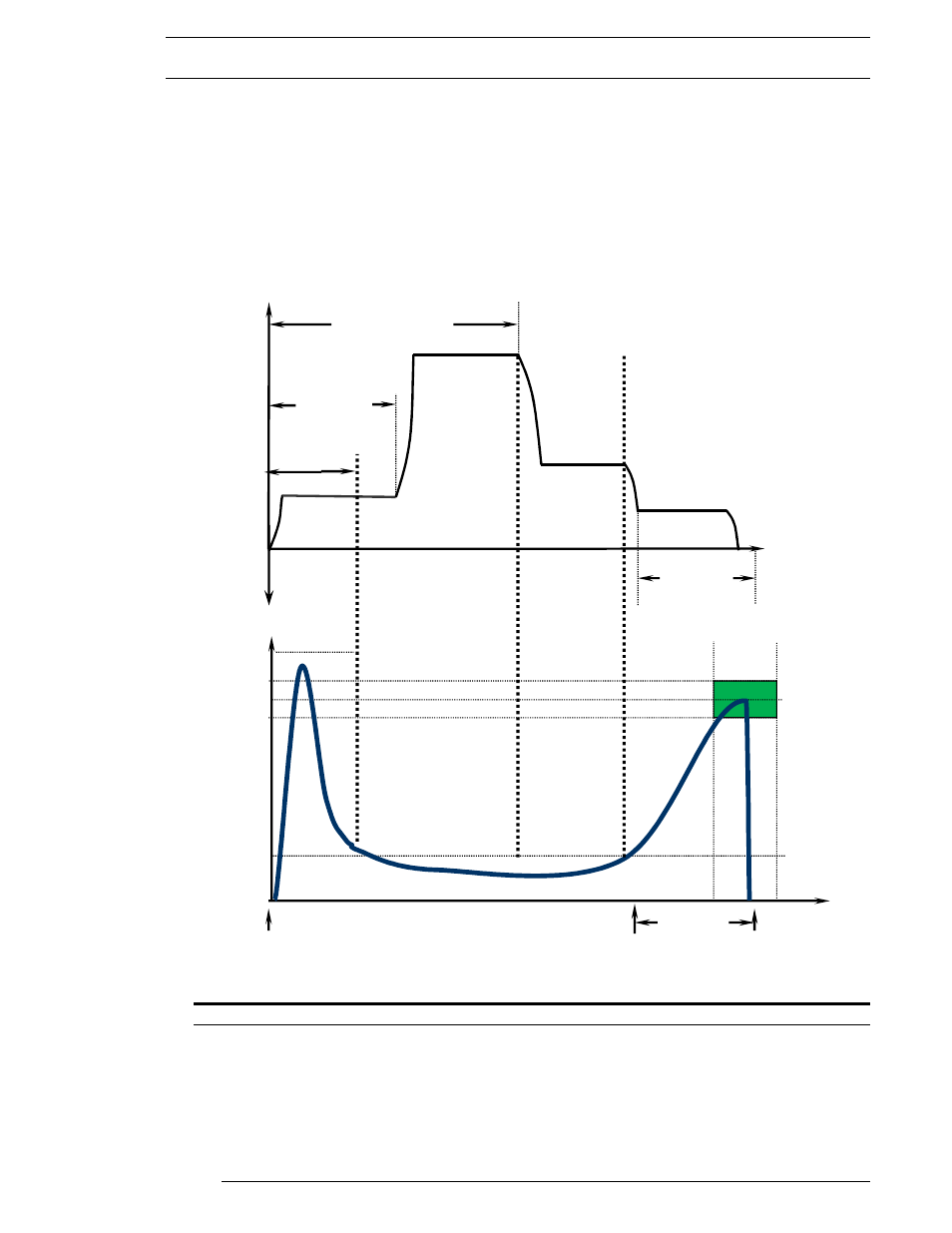

6.4.3 Torque Inhibit

The Torque Inhibit function is used to ignore high torque spikes during initial starting of the motor

or fastening process. Under normal fastening operations peak torque will stop the fastening

process (if Standard Torque is reached). This may not be desirable for applications with high

starting torque and lower fastening torque. Applications such as self-tapping screws and

application with high starting inertia may require this function.

Torque Inhibit is set by the number of revolutions that are required to be “ignored” during the

process. The Torque Inhibit Limit is a torque limit used as protection in case the amount of torque

monitored during the Torque Inhibit Revolutions is too high. If this torque limit is hit during the

Torque Inhibit process, then the spindle will stop and an Abnormal is output.

Fig. 6-4-3 Torque Inhibit Function

WARNING: The Torque Inhibit Revolutions setting should be set as low as possible for the

intended application to avoid ignoring torque readings as the fastener approaches the

seating point. If the fastener seats and the system is still in Torque Inhibit mode, possible

fastener/part and/or system damage may occur.

13: Standard Torque

14: Speed Change

Torque

Torque

Angle/Time

Speed

50: Initial Speed

40: Initial

Time

53: Torque

Speed

52: Slow

Down Speed

51: Freerun

Speed

61: Torque Inhibit

Revolutions

60: Freerun

Revolutions

42: Final

Time

Time/Revolutions

42: Final

Time

19: Torque Inhibit Limit