FEC MICRO NR User Manual

Page 45

FEC Micro NR Operations Manual

Chapter 4: System Setup and Wiring (Rev2.1: 12/12)

Page 4-11

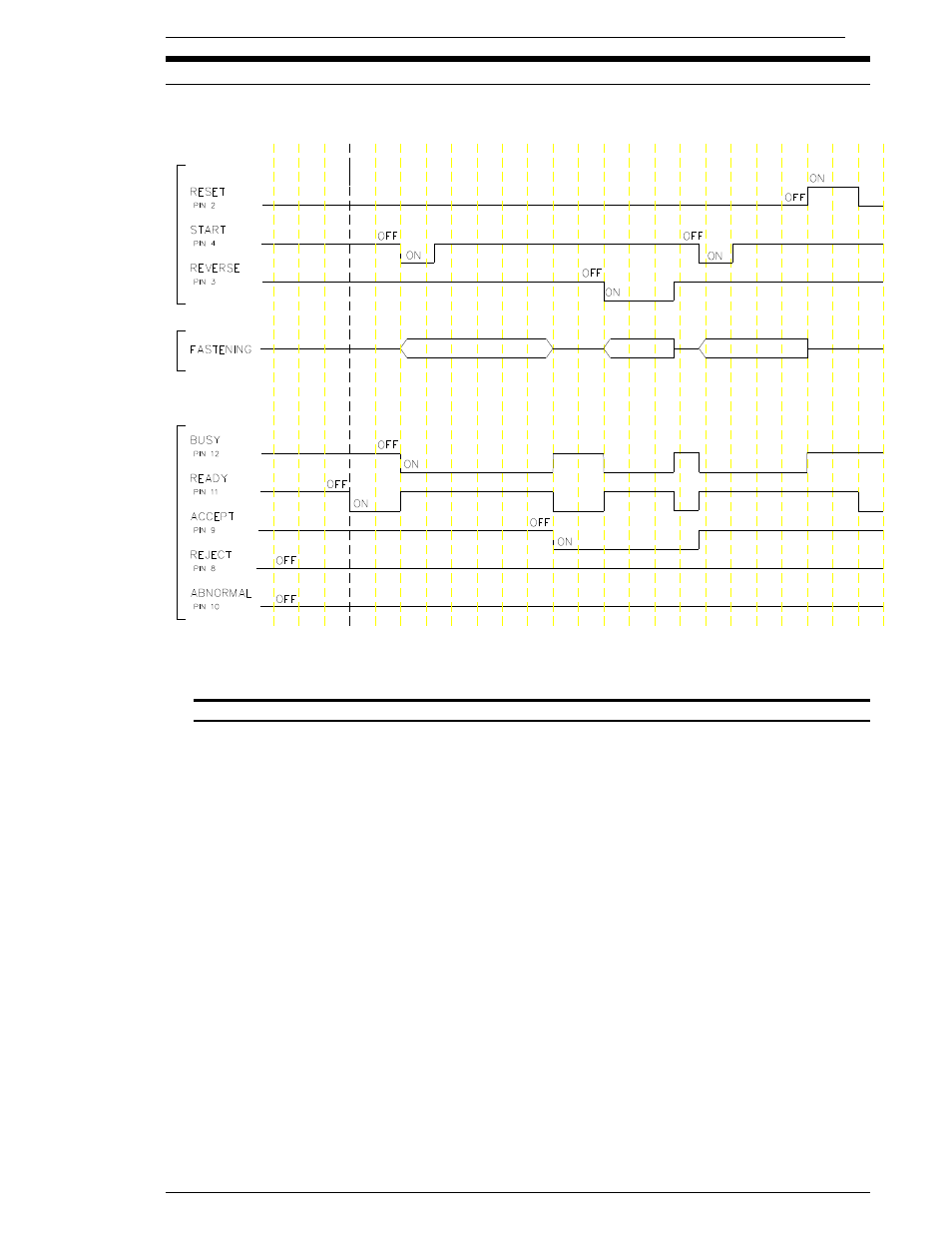

4.4 Signal Timing Chart

A. Basic Control Signals

FIG. 4-4 Basic Control Signals

{ Because the RESET input clears all fastening data, discrete outputs and communication

buffers, it should be activated only to clear a System Abnormal or to perform a required Zero

Check. The System will automatically reset with each fastening and a manual RESET

activation between cycles could result in data loss. The RESET signal requires a pulse of

100~500 milliseconds.

{ Once set on, the ACCEPT or REJECT signals will latch on until the start of the next cycle.

{ The START signal will not operate during RESET, REVERSE or ABNORMAL signal

activation. The START signal requires a pulse of 100~300 milliseconds for the AUTO START

mode. If the system is set-up in DEADMAN mode (Used mainly in handheld applications), this

signal has to stay on during the complete fastening cycle (until the BUSY signal goes low). If

the signal is prematurely disabled before the end of cycle, the spindle will immediately stop.

{ When the ABNORMAL signal is active, normal operation will cease. The Abnormal problem

must be cleared and a RESET must be input to clear the Abnormal output to begin normal

operation.

{ When using WORK SELECT inputs to change parameters activate or select the WORK

SELECT inputs at least 200ms BEFORE activating the start signal.