3 ratio control – Micromod Micro-DCI: 53SL6000 Single Loop Controller User Manual

Page 92

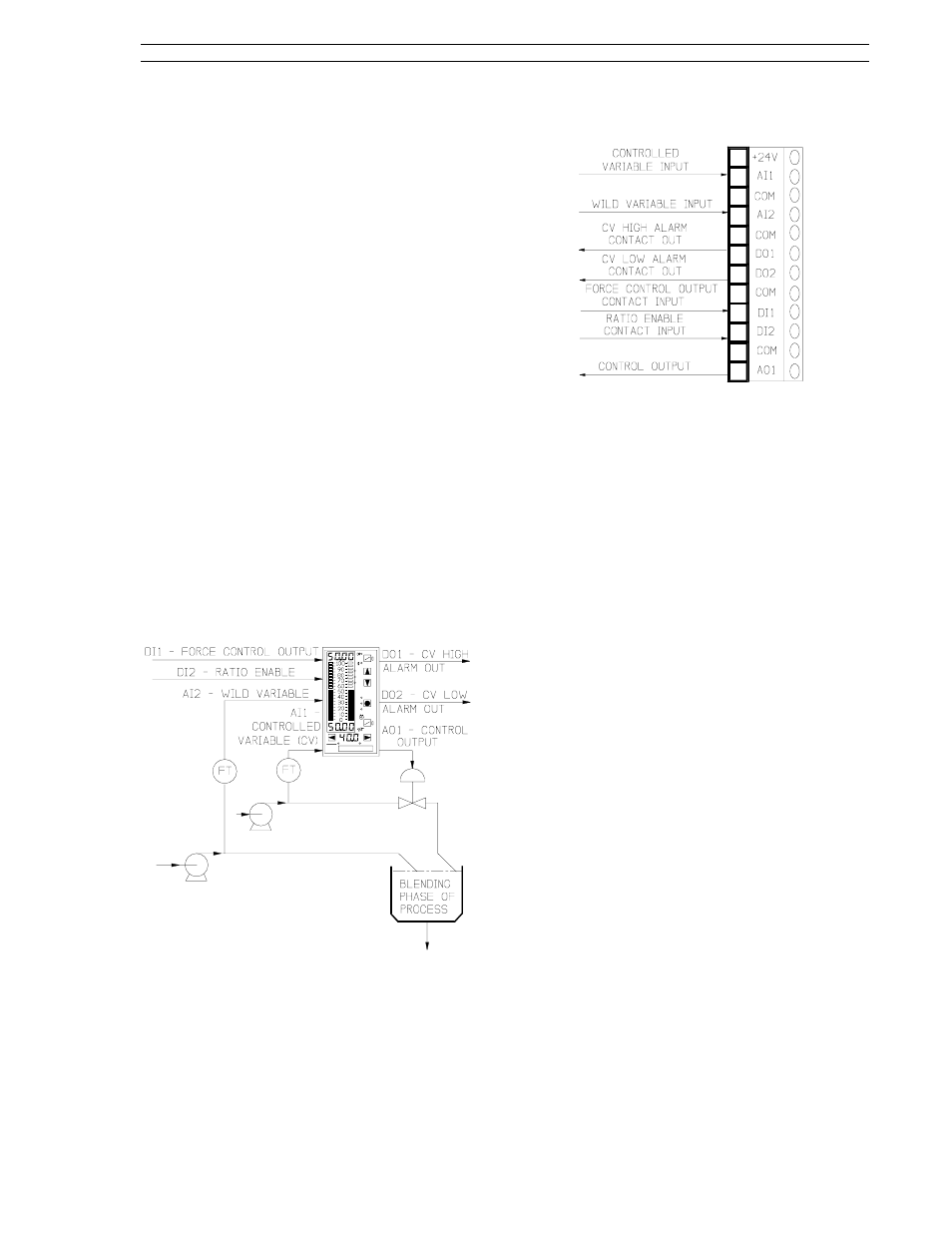

8.3 Ratio Control

Ratio control is used where one variable, called the

controlled variable, must be automatically main-

tained in definite proportion to another variable,

called the wild variable. Ratio control is imple-

mented with the controller default settings, the

SnGL control scheme, and the ratio setpoint K-SP

selected from the setpoint mode (ConF-cn.1-SPM)

parameter. A ratio control strategy is illustrated in

Figure 8-6. Field transmitters (e.g, flow meters)

must be installed in each variable line. Signals

from the controlled and wild variable transmitters

(AI1 and AI2 respectively) are received by the con-

troller which compares them and calculates the re-

quired correction that is applied as an output signal

(AO1) to a final control element (e.g., valve) in the

controlled variable line. The final element in the

controlled variable line is moved to alter line

throughput so that the predetermined ratio between

the two lines is maintained. The predetermined

ratio is set at the controller with the ratio/local (R/L)

push button in R. While in ratio control, the set-

point push buttons are used to set the desired ratio

value; when the R/L push button is in local control,

the setpoint push buttons modify only the setpoint

value. In local control, the controlled variable line

functions in single loop control mode.

Figure 8-6. Ratio Control Application

The signal connector is illustrated in Figure 8-7 and

the connector pin assignment descriptions are pro-

vided in the sections that follow. These sections

also contain the applicable display prompts that

may require configuration changes.

Figure 8-7. Ratio Control Signals

8.3.1 AI1 - Controlled Variable Input

This is the controlled line analog input signal value

that must be maintained in proportion to the wild

variable input value.

Applicable parameters that may require configura-

tion changes:

Section 5.2, conF-Ai.1-(SPan, ZEro, SQrt, bASE,

dFLt).

For CV alarms:

Section 7.7, conF-cn.1-(AiX, PL1, PL2, Adb).

8.3.2 AI2 - Wild Variable Input

This is the wild variable analog input signal value

that determines the required controlled variable in-

put as specified by the ratio setting.

Applicable parameters that may require configura-

tion changes:

Section 5.2, conF-Ai.2-(SPan, ZEro, SQrt, bASE,

dFLt).

Section 7.7, conF-cn.1-(Sh, SL, SSr, B1).

8.3.3 DO1 - Controlled Variable High

Alarm Contact Out

D01 is closed (on) when the controlled variable

value is not within the process alarm limit 1 (PL1)

setting.

Applicable parameter that may require configura-

tion change:

Section 5.6, ProG-do-inV1.

8.3.4 DO2 - Controlled Variable Low

Alarm Contact Out

D02 is closed (on) when the controlled variable

value is not within the process alarm limit 2 (PL2)

setting.

Section 8. Eight Control Strategies

53SL6000 Instruction Manual

8-5