3seg mode, 2 lseg mode – Micromod Micro-DCI: 53SL6000 Single Loop Controller User Manual

Page 52

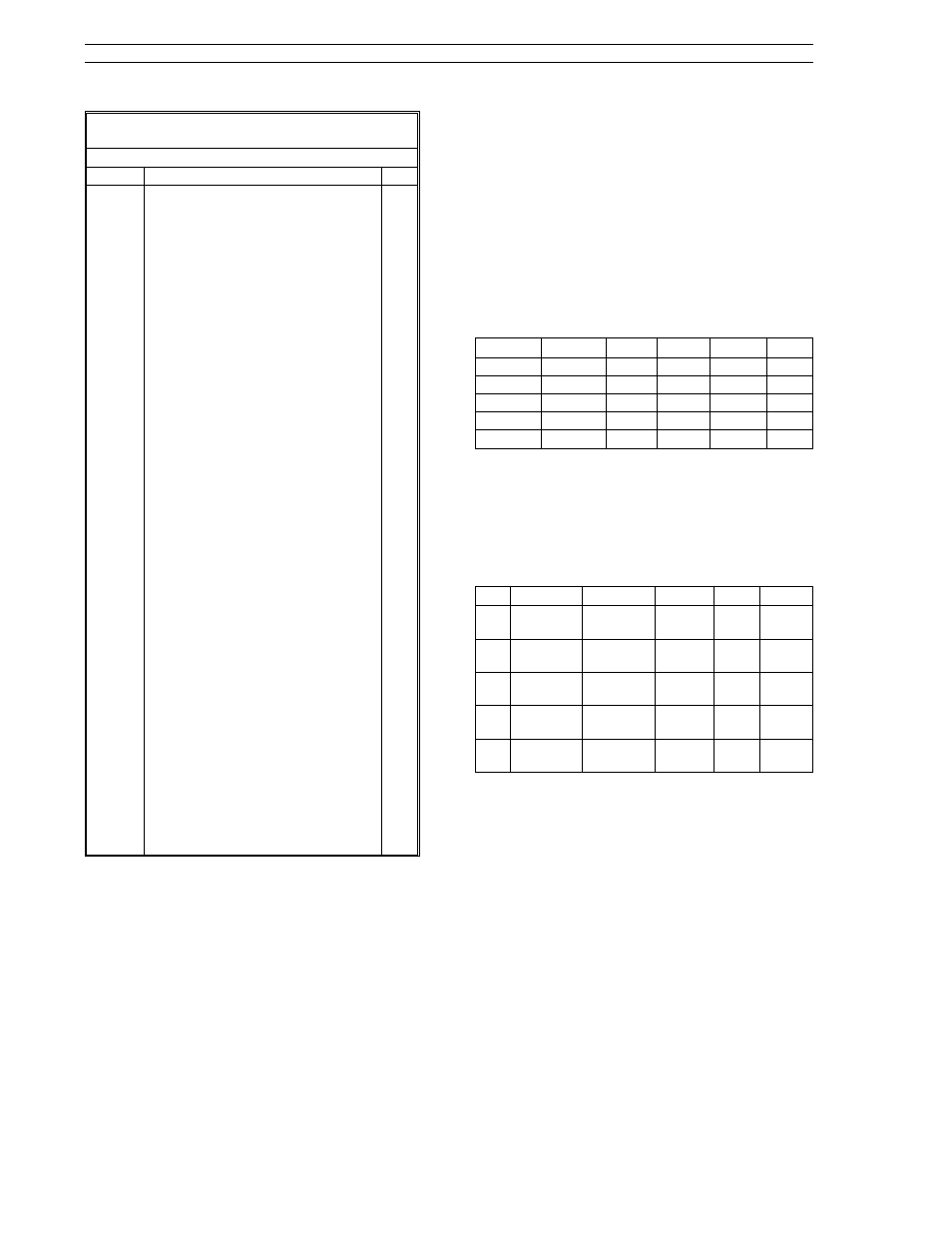

Table 6-1. Characterizer Parameters

(ProG Menu

→ chr Module)

Prompt

Description

Dft

K01 -

K26

Assignments for K01 through K26 for

the three segment (3SEG)

characterizer, linear segment (LSEG)

characterizer, the setpoint

programmer (PGrM), and the digital-

to-analog converter (DtoA) are as

follows

3SEG (executes 5 third order

polynomials):

K01 - K06: Six endpoints that

partition the 5

segments.

K07 - K10: Segment 1 (equation 1)

coefficients.

K11 - K14: Segment 2 (equation 2)

coefficients.

K15 - K18: Segment 3 (equation 3)

coefficients.

K19 - K22: Segment 4 (equation 4)

coefficients.

K23 - K26: Segment 5 (equation 5)

coefficients.

LSEG (13 ordered pairs for 12

segments. Each input value must

be greater than the previous one):

K01 - K13: input coordinates.

K14 - K26: output coordinates.

Ordered segment pairs are K01, K14;

K02, K15; etc.

PGrM:

K01 - K13: Entered time intervals in

whole seconds. Negative

numbers not permitted.

K14 - K26: Target analog output from

characterizer (per step).

DtoA:

K1: B input ramp rate (up).

K2: C input ramp rate (down).

K3: Lower output limit.

K4: Upper output limit.

0.0

6.2.1. 3SEG Mode

The third order polynomial segment characterizer

allows the user to define five adjacent segments.

Each segment has an independent third order poly-

nomial defining the relationship between the A in-

put value and the analog output value. Whenever

the A input value does not fall within any of the five

segments, a logical 1 value is produced at the char-

acterizer’s digital output; otherwise, a logical 0

value is present at the digital output. The charac-

terizer analog output value is forced to reflect the

value related to the nearest defined segment when-

ever the A input is outside all defined segments.

The five segments are defined by the constants K1

through K6. The values assigned to these con-

stants must be monotonically increasing, going

from K1 to K6, to ensure the segments are adja-

cent. Constants K7 through K26 are divided into

five groups, each with four constants. The group

acts as a set of coefficients for an individual seg-

ment’s polynomial as given by the equation and

table below:

Output

=

WA

3

+

XA

2

+

YA

+

Z

Equation Segment

W

X

Y

Z

1

K1-K2

K7

K8

K9

K10

2

K2-K3

K11

K12

K13

K14

3

K3-K4

K15

K16

K17

K18

4

K4-K5

K19

K20

K21

K22

5

K5-K6

K23

K24

K25

K26

This characterizer mode provides the capability to

linearize complex curves (e.g., thermocouple

curves). A linearization example of an E-type ther-

mocouple (operating range -115

°

to 1000

°

C) with

the characterizer A input provided in millivolts is as

follows:

Eq.

Segment

W

X

Y

Z

1

K1: -5.90

K2: 0.0

K7:

0.03947

K8:

0.1575

K9:

17.20

K10:

0.04199

2

K2: 0.0

K3: 13.42

K11:

0.004269

K12:

0.2143

K13:

17.01

K14:

0.02144

3

K3: 7.0

K4: 36.99

K15:

0.0007227

K16:

0.0769

K17:

15.12

K18:

9.264

4

K4: 36.99

K5: 61.02

K19:

0.0002274

K20:

0.02488

K21:

13.26

K22:

32.13

5

K5: 61.02

K6: 76.40

K23:

0.0001247

K24:

0.004976

K25:

11.95

K26:

60.8

Note: many of the values shown in this example

can not be entered directly at the front display

panel due to the limited size of the data entry dis-

play; however, the values given are easily loadable

via the communications network datalink interface

(requires the RS-485 option module).

6.2.2 LSEG Mode

The linear segment characterizer allows the user to

define a relationship between the A input and the

analog output value via a piecewise linear approxi-

mation. The approximation is made up of twelve

adjacent line segments. Each line segment end-

points are defined by two pairs of coordinates, re-

quir ing thirteen coor dinate pairs in all. The

coordinate values are stored in characterizer con-

stants K1-K26.

Micro-DCI

53SL6000 Controller

6-2