B.5 defaulting the database, B.6 analog input/output calibration values, B.7 watchdog led – Micromod Micro-DCI: 53SL6000 Single Loop Controller User Manual

Page 123

B.5 Defaulting the Database

The database can be restored to the factory set

default values by entering a 098 into the ProG-cS-

FiX parameter using the following procedure:

NOTE: Pass-keys will not be preserved if the

database is defaulted.

1.

Enter engineer mode by pressing and holding

the mode pb. OPEr appears in the green dro.

2.

Press the scroll forward pb until ProG appears

in the green dro.

3.

Press the enter pb to accept the ProG menu.

4.

If cS does not appear in the yellow dro, press

the scroll forward pb until it does.

5.

Press the enter pb to accept the cS prompt;

SchM (scheme, the first parameter) appears in

the green dro and the control scheme prompt

that was active (e.g., SnGL for single loop)

appears in the red dro.

6.

Press the scroll forward pb until the end of the

cS prompt list is reached, which is indicated by

the FiX prompt. Each time the scroll forward

pb is pressed, a new parameter name appears

in the green dro and its default setting appears

in the red dro.

7.

Press the enter pb to accept the FiX prompt;

the first digit in the red dro starts blinking.

8.

Use the scroll forward pb to make the first digit

a 0.

9.

Press the shift right pb so that the second digit

starts blinking.

10.

Use the scroll forward pb to make the second

digit a 9.

11.

Press the shift right pb so that the third digit

starts blinking.

12.

Use the scroll forward pb to make the third digit

an 8. 098 now appears in the red dro, but the

8 is still blinking.

13.

Press the enter pb to accept the 098. Three

zeros appear in the red dro. The green dro still

contains FiX and the yellow dro still contains

cS. The setpoint vertical bar indicates a

stopped condition with four separately lit areas

(no continuous bar).

14.

Press the mode pb; oFF starts blinking in the

red dro. Press the scroll forward pb to change

oFF to run and press the enter pb to exit engi-

neer mode.

B.6 Analog Input/Output

Calibration Values

The calibration values can be validated and altered

using 53HC2600 SL6 Configurator software appli-

cation package running on a personal computer.

Reference the software documentation and/or help

screens to display the Ai1, Ai2, and Ao1 biAS and

GAin prompts. Using the SL6 configurator, enter

the values from the calibration sheet into these

prompts.

The calibration values for the universal analog in-

put module can be validated and altered from the

controller display panel. See Table 5-8 for a list of

the calibration prompts and see Section 3 for dis-

play panel procedures in engineer mode.

NOTE: The factory set calibration constants for

the analog inputs and analog outputs were

recorded on the instrument calibration sheet

provided with the controller. As stated in the note

on the Trademarks page in the front of the book,

this sheet should have been retained in the event

one or more of the constants was inadvertently

changed to the wrong value, necessitating field

recalibration.

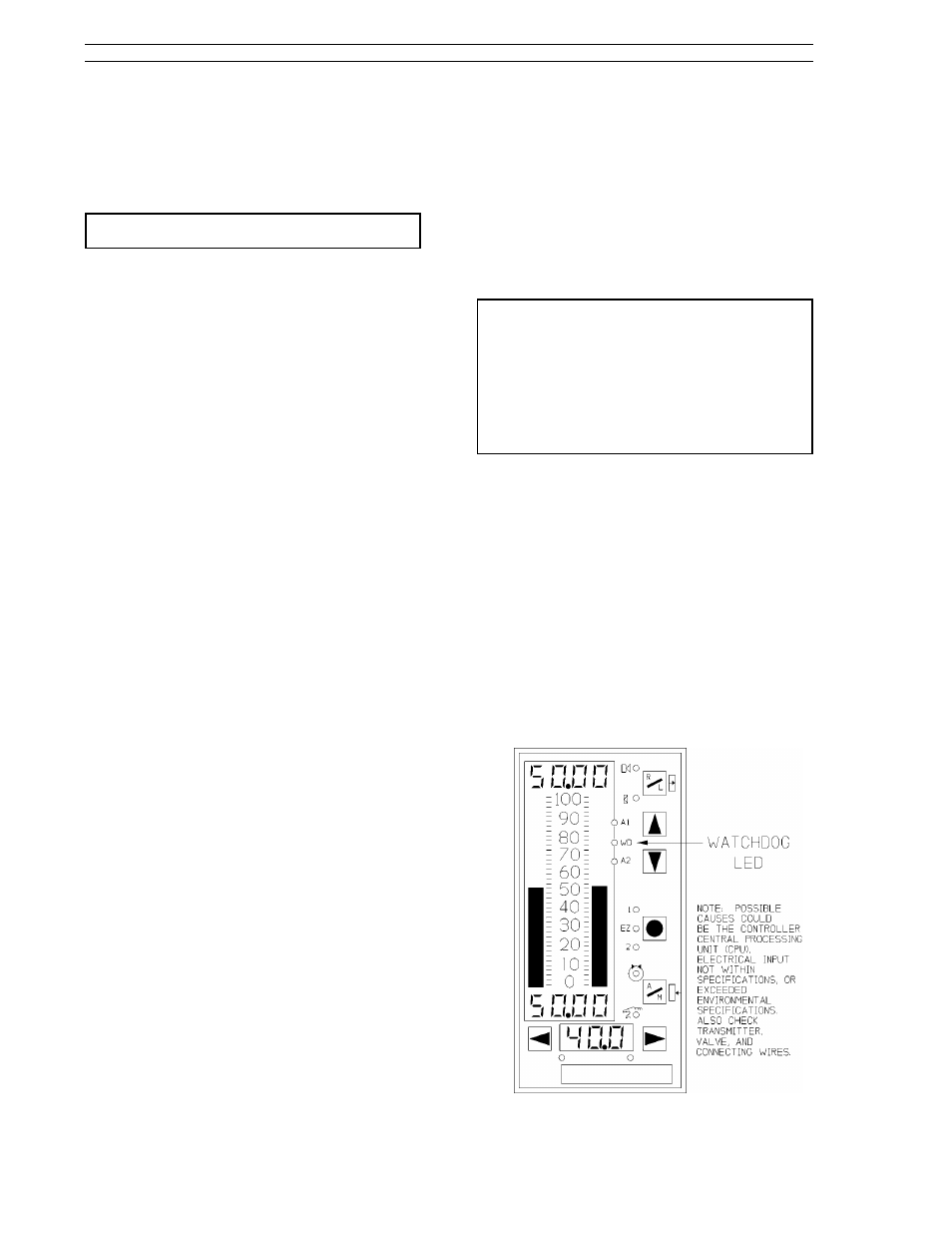

B.7 Watchdog LED

The location of the watchdog LED on the controller

faceplate is illustrated in Figure B-4. When active,

all outputs are forced to their power-off state. The

watchdog LED will activate for any one of three

conditions:

1.

Central Processing Unit (CPU) failure on the

display board or any other controller failure

that manifests itself as a CPU failure by caus-

ing the CPU to malfunction.

2.

Electrical input is not within the stated specifi-

cations provided in Section 1.3.

3.

Environmental specifications stated in Section

1.3 are exceeded.

Figure B-4. Watchdog LED

53SL6000 Instruction Manual

Appendix B. Maintenance and Parts List

B-6

PARTS