8 proportional speed floating control – Micromod Micro-DCI: 53SL6000 Single Loop Controller User Manual

Page 101

8.8 Proportional Speed Floating

Control

This control output is suitable for any of the control

schemes where the final control element is usually

a motorized valve. The controller output is pro-

vided at two discrete outputs, rather than the ana-

log output AO1. One discrete output drives the

motor in one direction and the other discrete output

drives the motor in the opposite direction. The MS1

and MS2 indicators activate, depending on the DO

driving the motor. The discrete output logic asserts

for a period of time that is proportional to the quan-

titative requirement of the corrective action. The

greater the error, the longer the discrete output

logic will be asserted. If the deviation is zero and

there is no signal on either discrete output, the

motor can be at any position within its operating

range; therefore, the motorized valve is said to be

floating. Since the motorized valved is moved at a

speed proportional to the deviation, and floats

when there is no output signal, this output type is

called proportional speed floating control.

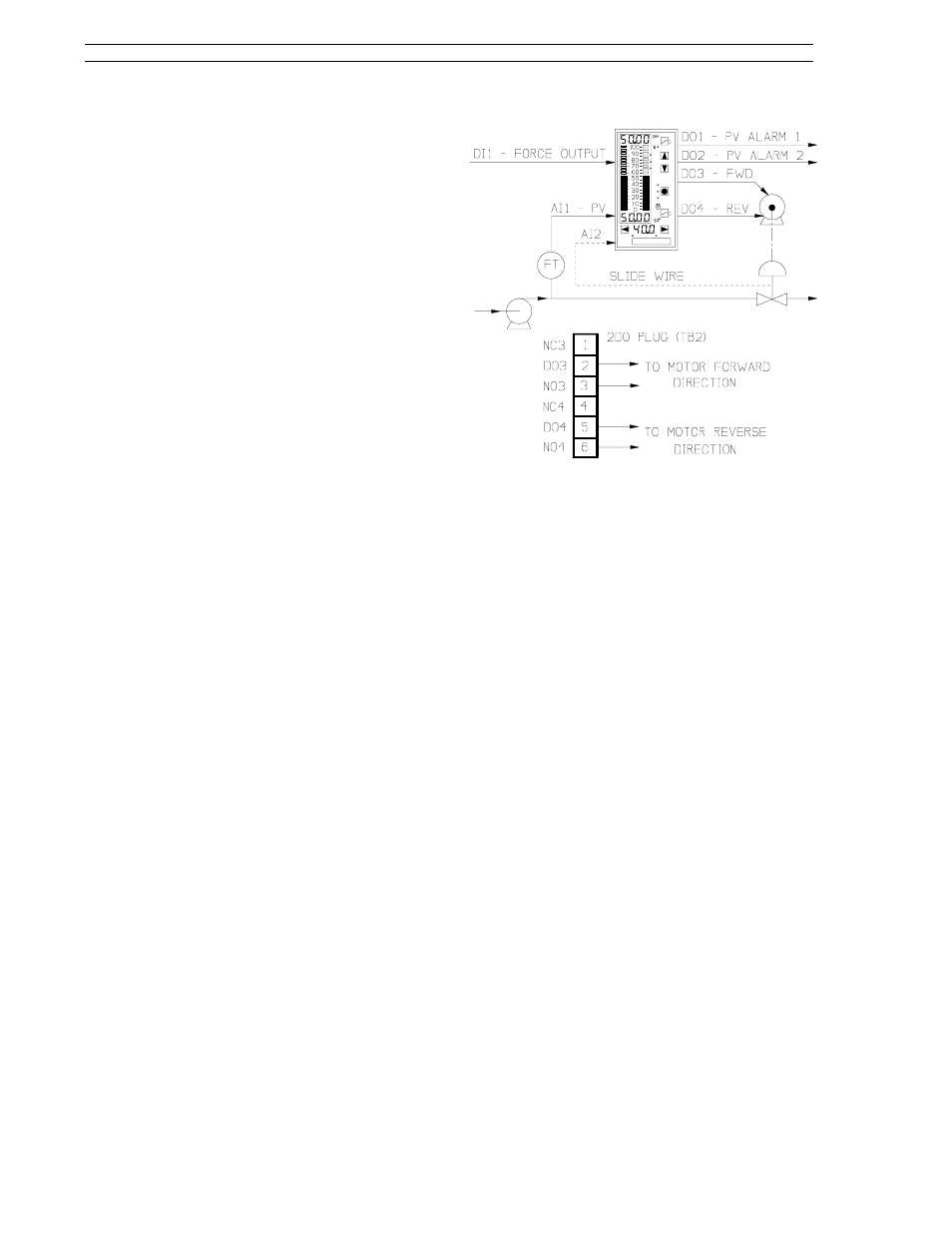

8.8.1 Motorized Valve Connections

The 2DI/2DO option module is required for propor-

tional speed floating control because the standard

discrete outputs DO1 and DO2 do not have relays.

It is NOT recommended that DO1 and DO2 be

used for this output application, as doing so

would require a motor interface (e.g., relays or

triac circuitry). An illustration of proportional

speed floating control output is provided in Figure

8-16. Also shown in the illustration are the wiring

connections at the 2DI/2DO module connector

TB2. The motor connections are not shown due to

product variations. The user must ascertain how

the leads are connected at the motor to cause it to

drive in the required direction for each active out-

put.

8.8.2 Configuration Requirements

Parameter inputs and path connections are re-

quired to initiate proportional speed floating con-

trol. The parameters affected apply only to control

module 1 (cn.1) of the conF menu and not control

module 2 (cn.2). The applicable path connections

and parameter entries are as follows:

Figure 8-16. Proportional Speed Floating

Control

Switch path connections (these switches can

be found in the cS module of the ProG menu):

•

ProG-do-do3.i should be at its default connec-

tion to Vup.

•

ProG-do-do4.i should be at its default connec-

tion to Vdn.

•

ProG-cS-doFb should be set to on if a valve

slide wire is to be used.

•

ProG-cS-cs.F should be connected to Ai.2.

This allows the slide wire feedback (see Figure

8-16) at Ai2 to be displayed in the yellow dro.

The value displayed is in percent of the valve

position and not percent output. This is an

optional connection because some valves do

not provide slide wire output.

Parameter entries:

•

Zero-out Manual Rest (conF-cn.1-Mr). Allow

full control range by setting output low-limit

(conF-cn.1-oL) to -100 and output high-limit

(conF-cn.1-oh) to 100.

•

Enter an output duty cycle value in seconds in

conF-cn.1-dcp. This value specifies, in sec-

onds, the length of the cycle period over which

the digital outputs VuP and Vdn are calculated.

This time must be set based on the charac-

teristics of the final control element and the

amount of cycling permitted. A shorter dcp

increases motor cycling and a longer dcp de-

creases motor cycling, which slows the control

response. For minimum cycling of the final

53SL6000 Instruction Manual

Section 8. Eight Control Strategies

8-14