0 commissioning, 1 overview, 2 proportional action (pb) – Micromod Micro-DCI: 53SL6000 Single Loop Controller User Manual

Page 104: 3 integral action (tr)

9.1 Overview

Commissioning is an iterative process of refining

the proportional band - Pb (Pb.2), integral or reset

time - tr (tr.2), and derivative time - td (td.2) pa-

rameter values for each active control module.

Collectively, these three control action parameters

are called the PID and can be accessed from the

oPEr menu if they are enabled for display with the

conF-OPr-Pid.E parameter or they can be ac-

cessed from the conF-cn.1(cn.2) module. The val-

u e s e n t e r e d f o r t h e se th r ee pa r am et er s ar e

dependent upon the process application and de-

sired controller response to disturbances. It is not

necessary to have all three parameters active for

every process application. If a control strategy is

implemented that uses both control modules (cn.1

and cn.2), then the PID parameters for each control

module may require configuring.

9.2 Proportional Action (Pb)

In proportional action (conF-cn.1[cn.2]-Pb) there is

a comparative relationship between the controller

output signal magnitude and the calculated error,

which is the difference between the measured

process variable feedback and the desired set-

point. The proportional action of the controller is

set as a percentage of the proportional band (%PB)

from 2% to 1000%. If the %PB (Pb) is set at 2%, a

small percent change in error causes full scale out-

put signal magnitude (narrow proportional band).

Conversely, If the %PB (Pb) is set at 1000%, a

large percent change in error causes full scale out-

put signal magnitude (wide proportional band).

Because it is the process itself that provides the

feedback as the process variable, the controller

output must be correctly spanned to the maxi-

mum/minimum swing of the process control ele-

ment, and it is assumed the output signal sent to

the the process control element will positionally

alter it to null the calculated deviation error.

Process dynamics can therefore adversely affect

correct process control element positioning. For

example, two process disturbances that cause the

same calculated deviation error will not necessarily

cause a repositioning of the process control ele-

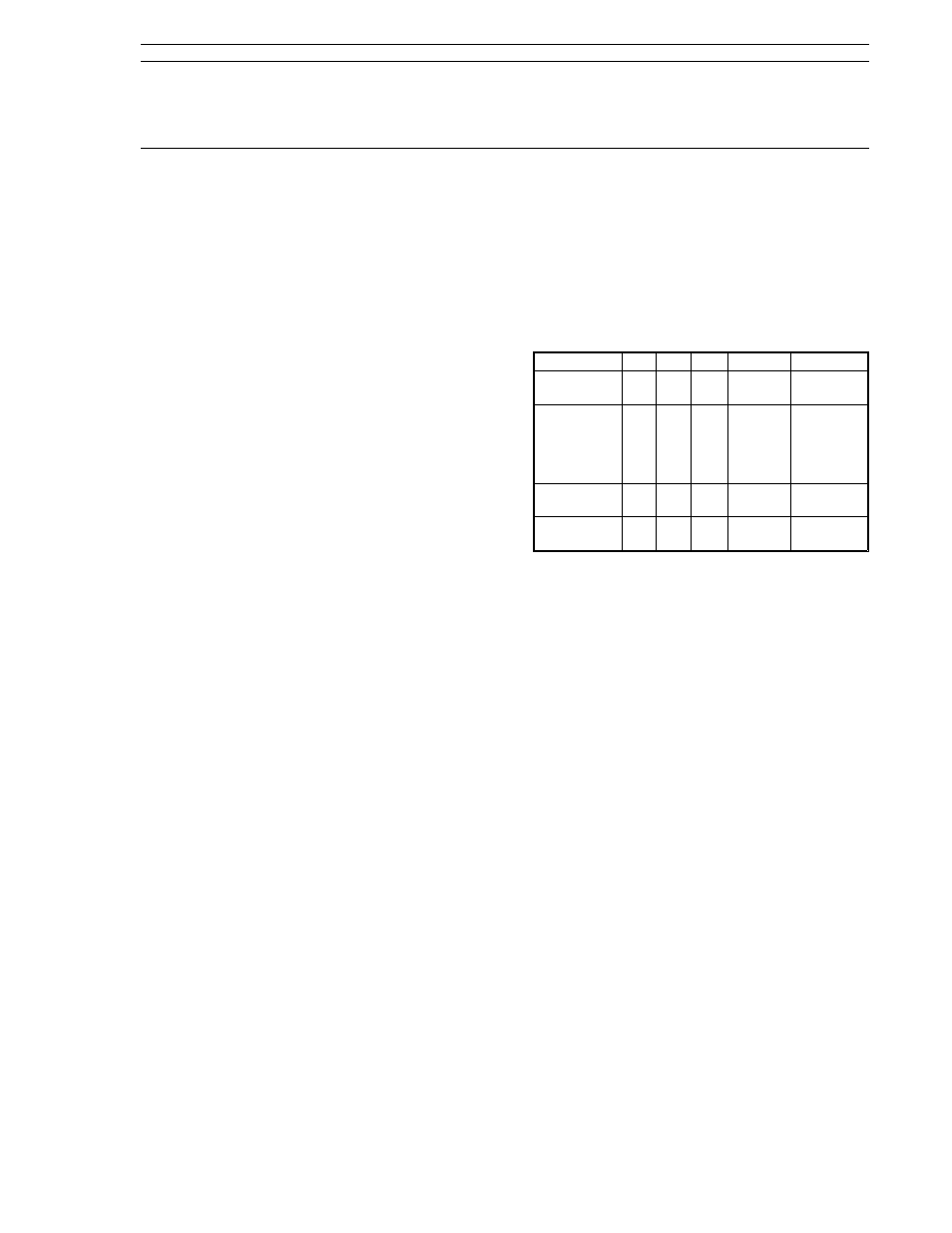

ment. As shown in the table, Disturbance 1 caused

an error of 3. The process control element position

was changed to overcome the error and restore PV

back to setpoint, but the cause of the disturbance

was not removed; therefore, the controller output

must remain at its new position to keep the PV at

10. With disturbance 2, an error of identical magni-

tude (3) is created; the process control element will

not move because it is already resting at its

spanned value for that output signal level

even

though the process has not been restored to the

desired setpoint of 10. The cumulative effect on

process control of this inherent deficiency of pro-

portional action is called offset error (off from set-

point).

Disturbance

SP

PV

Error

Output

Action

quiescent

10

10

0

no

change

none

1

10

7

3

new

value

change

process

control

element

position

quiescent

10

10

0

same as

for 1

none

2

10

7

3

same as

for 1

none

If offset error occurs within a tolerable range, it can

be ignored; if it occurs as an unacceptable value

with

±

tolerable variances, it can be countered with

manual reset (Mr). There is an Mr prompt that that

can be accessed from each control module, cn.1 or

cn.2. Manual reset is entered as a value from 0%

to 100% output to compensate for the deviation

from setpoint that proportional action can not elimi-

nate. Because manual reset is entered as a fixed

value, it is limited with respect to process dynam-

ics. An alternative to manual reset is integral ac-

tion (tr).

9.3 Integral Action (tr)

Integral action (conF-cn.1[cn.2]-tr) augments pro-

portional action to cause the controller to drive the

process control element until the process deviation

is nulled. It is sometimes called reset, which

means return to setpoint. Integral action produces

a signal value that is a function of the deviation

from setpoint and the %PB setting. For example, if

setpoint was at 500

°

F and the controlled process

temperature dropped down to

400°

F, there would

be a 100

°

F deviation. If %PB had been set at 10%,

then the integral action in the first repetition interval

would be 10% x 100

°

or 0.1 x 100

°

= 10

°

. The

process control element would be moved until tem-

perature increased an additional 10

°

from 400

°

to

410

°

. In the second repetition interval, integral ac-

tion would be 10% x 90

°

or 0.1 x 90

°

= 9

°

. The

9.0 Commissioning

Section 9. Commissioning

53SL6000 Instruction Manual

9-1