8 easy-tune – Micromod Micro-DCI: 53SL6000 Single Loop Controller User Manual

Page 106

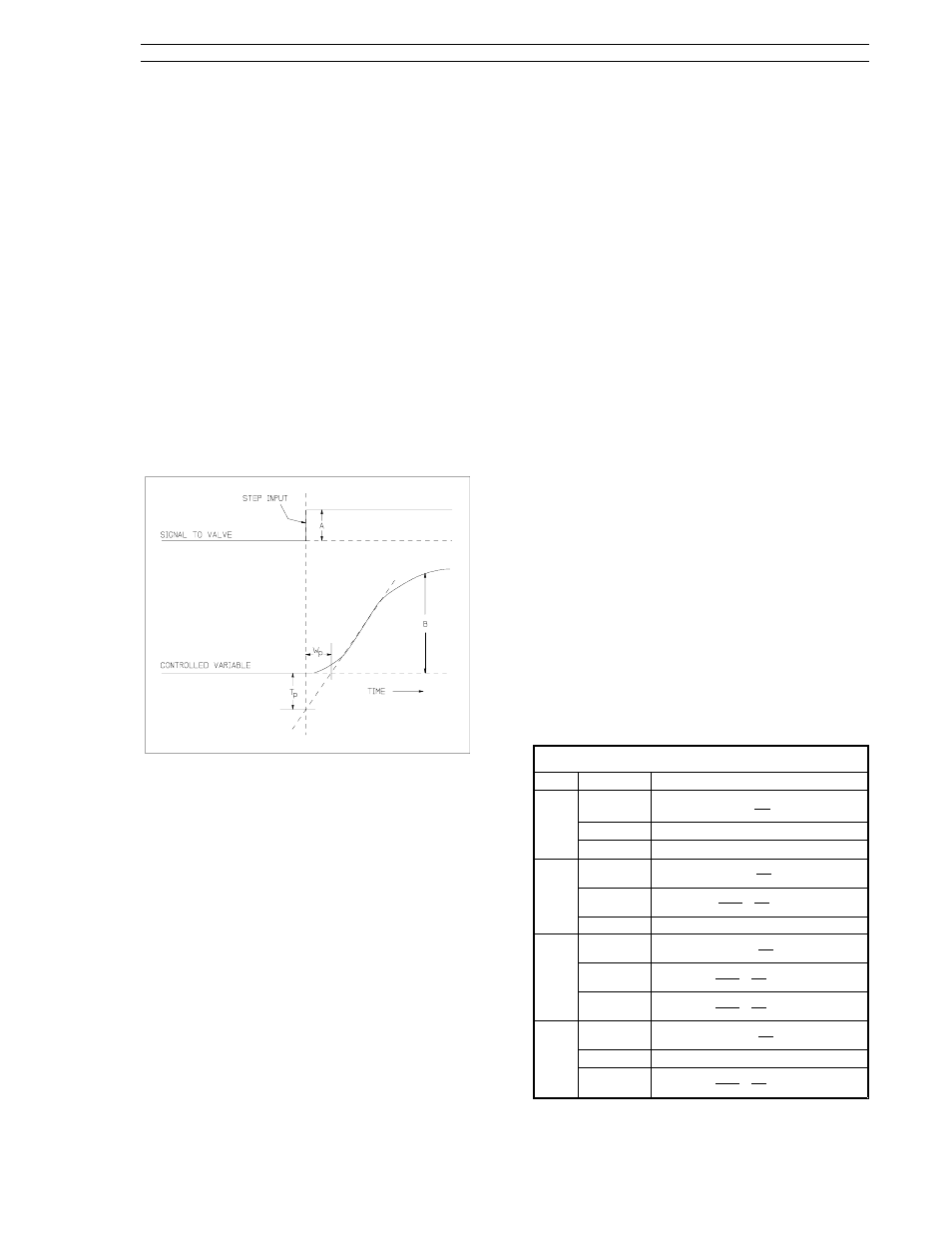

nitude of the step in percent of full signal span

A. Also plot a graph of the resulting transient

curve traced by the controlled variable.

3.

Draw a straight line tangent to a point on the

curve having the greatest slope (most linear).

4.

Measure the apparent dead time Wp in min-

utes as shown in Figure 9-1.

5.

Measure Tp, the product of the slope and dead

time as shown in Figure 9-1. This value should

be expressed in percent of full scale span.

6.

Using the multipliers provided, compute the

best settings as follows:

•

Proportional (P): Pb = (100Tp)/A.

•

Proportional and integral (PI): Pb =

(100Tp)/A; tr = 3Wp.

•

P r o p o r t i o na l, in te gr a l, an d d er i va ti ve

(PID): Pb = (80Tp)/A; tr = 2Wp; td =

0.5Wp.

Figure 9-1. Typical Step Response Record

9.8 Easy-Tune

The Easy-Tune algorithm approximates a first or-

der time lag with gain and dead-time to determine

the optimal PID characteristic constants. The

Easy-Tune sequence is graphically illustrated in

Figure 9-2. In the figure, the first step change is

used to calculate a preliminary estimate of the first

order time lag (Tp) and the dead-time (Wp) by

building an approximated process step response

curve model. Detailed illustrations of this approxi-

mation are shown in Figures 9-3 and 9-4. The

second step change, shown in Figure 9-2, is used

to calculate the process gain (Kp) measured as the

proportionality between the output step change and

process response. Using the same techniques il-

lustrated in Figures 9-3 and 9-4, the final estimates

for the time lag (Tp) and dead-time (Wp) values are

also made as the process step response curve

decays after the second step change is removed.

The values for Tp, Wp, and Kp, are then applied to

the ITAE (Integral Time Absolute Error) equations

given in Table 9-1. The equation results can be

previewed or allowed to be automatically entered

into the tuning constants P, I, D for the selected

loop. Values entered into the tuning constants are

limited to controller specifications as follows:

Proportional (EPb)

1000 - 2

Integral (Etr)

200 - 0.02, 0 (off)

Derivative (Etd)

8 - 0.01, 0 (off)

Before executing Easy-Tune the following must be

considered:

1.

For slow processes, be sure the process vari-

able is steady before executing Easy-Tune.

2.

Disturbance of the process during Easy-Tune

execution may result in a false process charac-

terization.

3.

Feed forward control must be OFF.

4.

If the ratio of process dead-time Wp and the

process time lag Tp is greater than 0.5, it is

recommended that the PID control mode be

used (e.g., cM = PID in Table 9-2).

5.

Processes that act as pure integrators can not

be tuned by Easy-Tune because those proc-

esses have no self regulation, as only one

value of the controller output is able to cause a

steady state process.

6.

In rare cases, a process response may not be

satisfactorily approximated as a first order time

lag with gain and dead-time.

Table 9-1. ITAE Equations

Mode

Action

Equation

P

PB in %

204K

p

(

W

p

T

p

)

1.084

TR (Min)

0

TD (Min)

0

PI

PB in %

116.4

K

p

(

W

p

T

p

)

0.977

TR (Min)

T

p

40.44

(

W

p

T

p

)

0.68

TD (Min)

0

PID

PB in %

73.69

K

p

(

W

p

T

p

)

0.947

TR (Min)

T

p

51.02

(

W

p

T

p

)

0.738

TD (Min)

T

p

157.5

(

W

p

T

p

)

0.995

PD*

PB in %

54.38

K

p

(

W

p

T

p

)

0.947

TR (Min)

0

TD (Min)

T

p

157.5

(

W

p

T

p

)

0.995

*Empirical estimates not based on ITAE method.

Section 9. Commissioning

53SL6000 Instruction Manual

9-3