6 control scheme parameters – Micromod Micro-DCI: 53SL6000 Single Loop Controller User Manual

Page 82

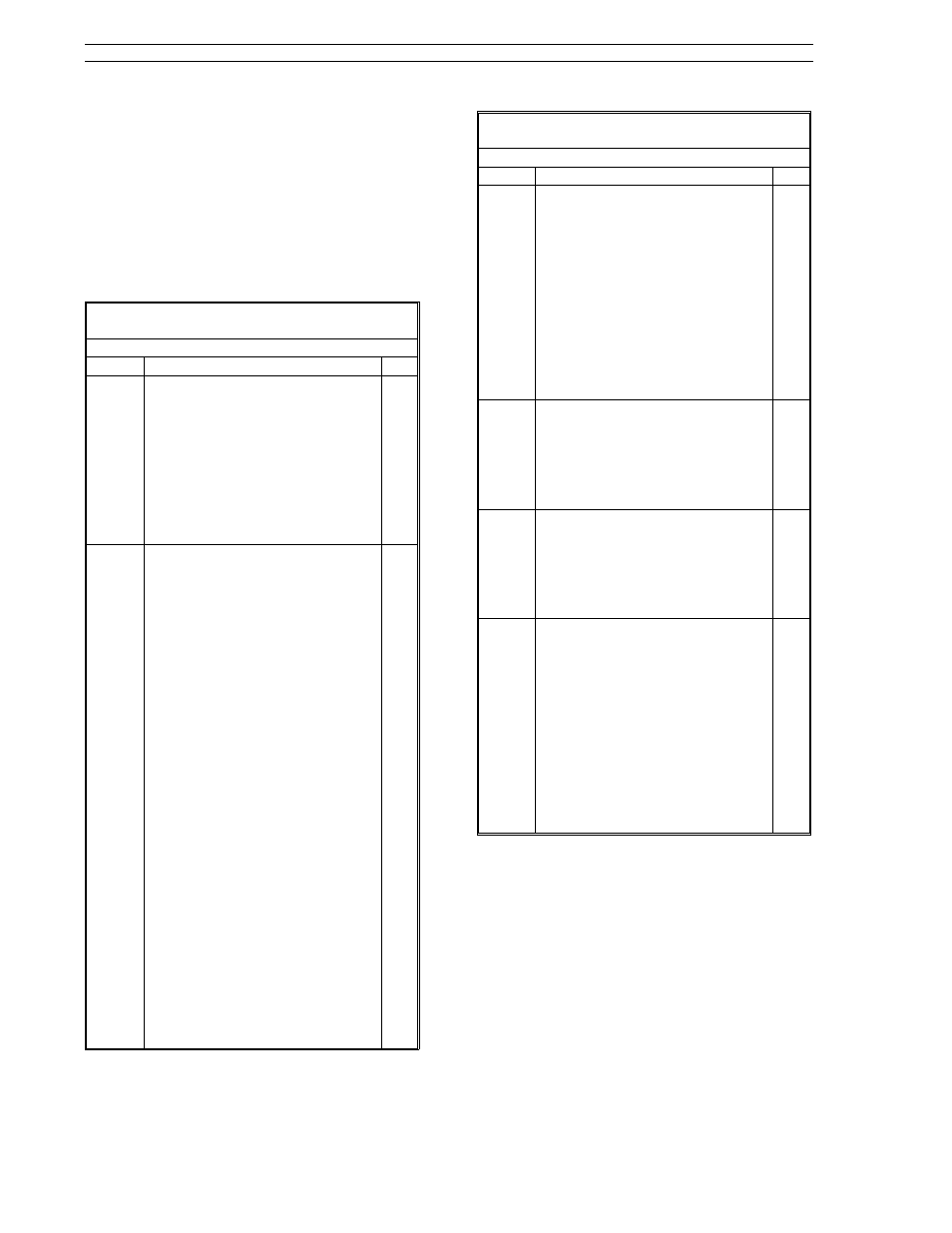

7.6 Control Scheme Parameters

Table 7-2 provides the control scheme ProG-cS

module parameters. These parameters set the ba-

sic operation of the control scheme block and de-

termine the input signal sources. Whenever these

parameters are edited, control operation is turned

off as when any other ProG menu parameter is

edited.

Table 7-2. Control Scheme Parameters

(ProG Menu

→ cS Module)

Prompt

Description

Dft

SchM

Control Scheme

This is a mode switch used to select

the control scheme. Control

scheme selections are as follows:

SnGL:

Single loop control.

cASc:

Cascade control.

L.LiM:

Low limiter (high override)

control.

h.LiM:

High limiter (low override)

control.

in.Ld:

Indicator/Loader operation.

SnGL

cS.A

cS.b

cS.c

cS.d

cS.E

cS.F

Control Scheme cS.A - cS.F Input

s

Specifies connections to the cS.A -

cS.F inputs of the control scheme.

Input selections are as follows:

0:

A constant value input of 0.0.

Ai1:

The standard analog input 1

value or a constant value

previously loaded into the Ai1

register.

Ai2:

The standard analog input 2

value or a constant value

previously loaded into the Ai2

register.

Ai3:

The optional analog input 3

value or a constant value

previously loaded into the Ai3

register.

Ai4:

The optional analog input 4

value or a constant value

previously loaded into the Ai4

register.

Ai5:

A constant value previously

loaded into this register.

Ai6:

A constant value previously

loaded into this register.

Ai7:

A constant value previously

loaded into this register.

Ai8:

A constant value previously

loaded into this register.

A03:

Looped-back value from A03

register.

Fnc:

The function generator

analog output.

Ai1

Ai2

0.0

Ai7

0.0

0.0

Table 7-2. Control Scheme Parameters

(ProG Menu

→ cS Module)

Prompt

Description

Dft

PVt

Process Variable Tracking

Specifies whether the setpoint

should be forced to match the

current process variable cS.A input

when loop 1 is not in automatic

control. When PVt is set to YES, the

setpoint automatically tracks the

process variable whenever loop 1 is

in manual or forced output

operating mode (output tracking).

Process variable tracking eliminates

process bumps when switching to

automatic from manual or forced

output (output tracking) operation.

no

doFb

Digital Output Feedback

When set to YES, it enables the

valve position value from the slide

wire to be displayed in the yellow

dro. This parameter is applicable for

proportional speed floating control

output.

no

EXrF

External Reset Feedback

When set to YES, the PID reset value

comes from an external source via

the control scheme cS.E input.

When set to no, the PID reset value

is feedback from the control

scheme output.

no

PVt.2

Process Variable Tracking 2

Specifies whether the setpoint

should be forced to match the

current process variable cS.b input

when loop 2 is not in automatic

control. When PVt.2 is set to YES,

the setpoint automatically tracks

the process variable whenever loop

2 is in manual or forced output

operating mode (output tracking).

Process variable tracking eliminates

process bumps when switching to

automatic from manual or forced

output (output tracking) operation.

no

53SL6000 Instruction Manual

Section 7. Control Scheme Block

7-24