Connecting wiring – Echelon LonPoint Module User Manual

Page 44

4-8

Installation and Wiring of Base Plates

Connecting Wiring

Route network, power, and input/output cabling into the electrical enclosure using

suitable conduit fittings, bushings, or wire glands. It is good practice to separate the

input/output cabling as much as possible from the network and power cabling,

especially if low level analog signals are being supervised. Once the cabling has been

brought into the electrical enclosure, leave a service loop of 6 inches (15cm) of cable

to simplify wiring the Type 1 Base Plate. Dress the cables using tie wraps or tape to

ensure that the cabling is not compressed or caught when the base plate is screwed

into place.

Strip the cable jacket and wire conductors. The base plate screw terminals will accept

26AWG (0.4mm) to 12AWG (2.2mm) wire, which should be stripped to a length of

0.32” (8mm). Although not required, it may be useful to use a soldering iron to tin the

stripped lengths of any stranded wires to prevent fraying and inadvertent contact

with adjactent terminals. The screw terminal blocks on the real panel of the Type 1

Base Plate are color coded to simplify wiring. The color coding scheme is shown in

table 4.1. The optimum tightening torque for the Type 1 Base Plate screw terminals

is 4 lbs. in. (0.5Nm) maximum. The ideal flathead screwdriver tip width is 0.125”

(3mm).

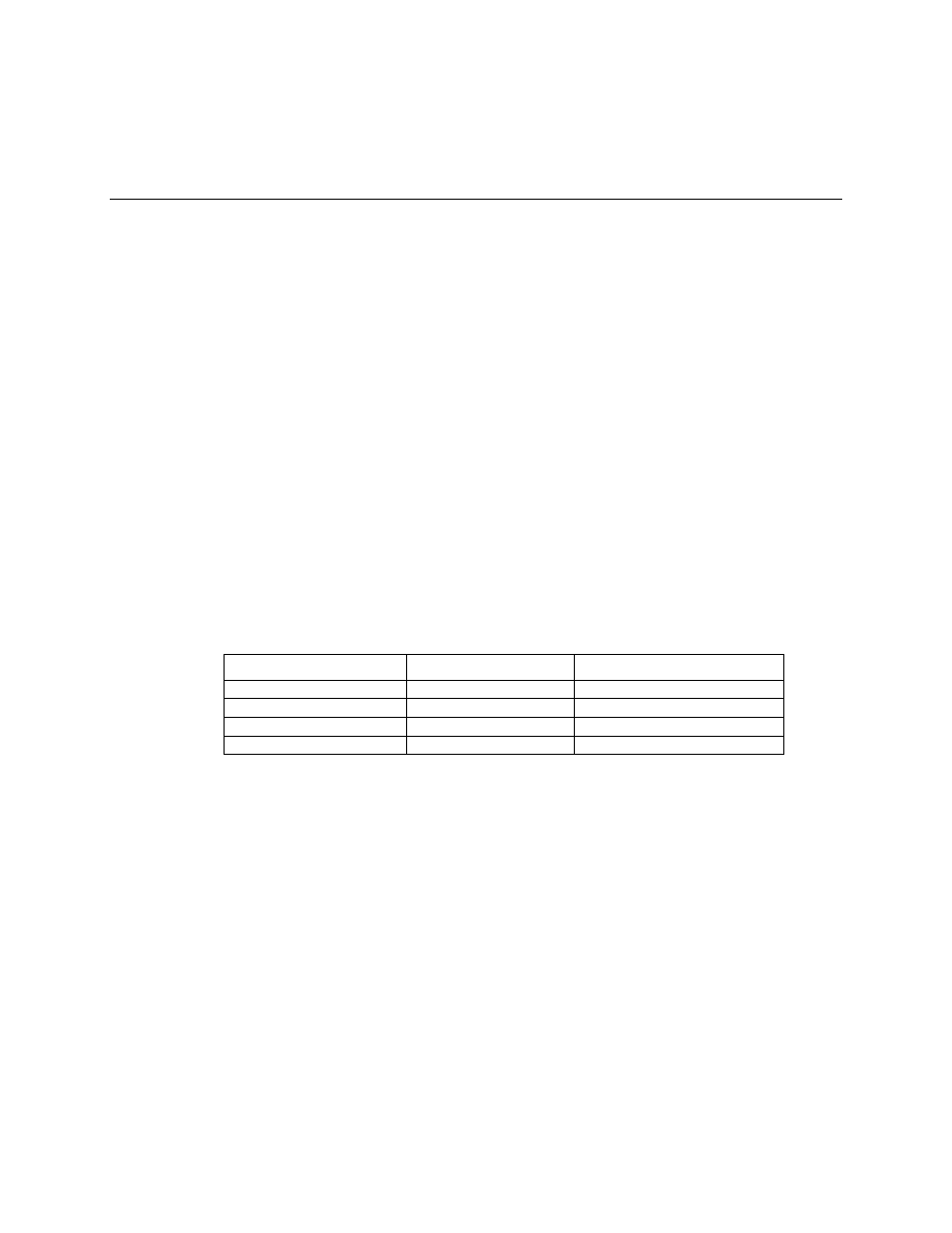

Table 4.1 Type 1 Base Plate Terminal Block Color Coding*

Terminal Number

Terminal Color

Function

1 - 4

Orange

Network

5

Orange

Cable shield, if used

6 - 9

Black

Power

10 - 18

Green

I/O

* In beta release Type 1 Base Plates, terminals 5 and 14 were

connected together but not connected to any I/O. In Type 1 Base

Plate marked 1A, terminal 5 is floating and may be used to

connect cable shield wires; terminal 14 is reserved for I/O.

Two sets of screw terminals are provided for both the power and network wiring

connections. These connections are internally jumpered on the Type 1 Base Plate

PCB to provide continuity of the network and power wiring, even if no LonPoint

module is installed, as shown figure 4.8. This feature permits the base plate wiring

to be pre-installed and the network and power circuits checked for continuity

throughout the installation, before a single LonPoint module is ever installed. This

feature also prevents network and power interruptions as a result of hot-swapping

LonPoint modules during commissioning or service operations. Finally, providing

two sets of screw terminals permits incoming and outgoing wiring to be landed at

separate screw terminals without the need to insert more than one wire in any given

screw terminal.