Generac Power Systems NP-40G User Manual

Page 94

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

________________ Section 6.4- ENGINE IGNITION SYSTEM

TESTING FOR SPARK:

To test the Ignition system, a suitable spark tes

ter may be used. Such spark testers are commer

cially available. Test the system as follows:

1. Disconnect the high tension lead from the spark

plug.

2. Attach the spark plug

high tension lead to the

spark tester terminal.

3. Connect the spark tester

clamp to the engine cylin

der head.

4. Crank the engine rapidly.

Engine must be turning at

350 rpm or more. If spark

Jumps the tester gap, you

may assume the ignition

system is operating satis

factorily.

If sparking across the tester gap does-NOT

occur, go to XHECK POWER SUPPLY".

CHECKING ENGINE MISS:

To determine if an engine miss is Ignition related,

connect the spark tester In series with the spark

plug’s high tension lead and the spark plug. Then,

start the engine. If spark jumps the tester gap at

regular intervals but the engine miss continues, the

problem is In the spark plug or in the fuel system.

CHECK POWER SUPPLY:

When the engine is being cranked, battery volt

age should be available from the Engine Controller

circuit board to a 4-termlnal connector via Wire 14.

From the 4-termlnal connector, battery voltage

should be available to the Ignition Module via Wire

14 (RED wire). And battery voltage should be avail

able from the Ignition Module to the Ignition Sensor

via a RED wire. If this 12 VDC power supply is not

available, the ignition system will not function. To

check the power supply, proceed as follows using

a volt-ohm-milliammeter (VOM):

1. Gain access to the control panel interior.

2. In the panel, locate the 3-pin connector that

Interconnects the Ignition Module and the ignition

Sensor.

3. Press down on the connector lock tang and

disconnect the two connector halves.

NOTE: A single large black lead carries the three

leads from the Ignition Sensor to the 3-pln MALE

connector. The three leads from the Ignition Mod

ule (brown, green and red) attach to the 3-pln FE

MALE connector.

4. Set the VOM to a scale

that will allow battery volt

age to be read (about 12

volts DC).

5. Connect the meter test

leads across the center FE

MALE pin (RED wire) and

frame ground.

6. Hold the Start-Run-Stop

switch at "START". The

meter should read battery

voltage.

If battery voltage Is NOT indicated, go to Step 7.

If battery voltage IS Indicated, go to "CHECK IGNI

TION SENSOR^..

7. Now locate the 4-termi

nal connector in the panel.

Connect the VOM test

leads across the terminal

and frame ground. Crank

the engine and the VOM

should read battery volt

age.

a. If battery voltage is

indicated now but was

NOT Indicated In Step 6,

test Wire 14 (RED) be

tween the 4-terminal

connector and the Igni

tion Module. If wire is

bad, repair or replace as necessary.

b. If battery voltage Is NOT Indicated In Step 7,

test Wire 14 between the 4-terminal connector

and the Engine Controller circuit board. Repair

or replace as necessary.

CHECK IGNITION SENSOR:

1. In the 3-pln connector plug half from the Ignition

Module, locate FEMALE Pin 1 to which the BROWN

wire connects.

2. Connect a jumper wire from FEMALE Pin 1

(BROWN wire) to frame ground.

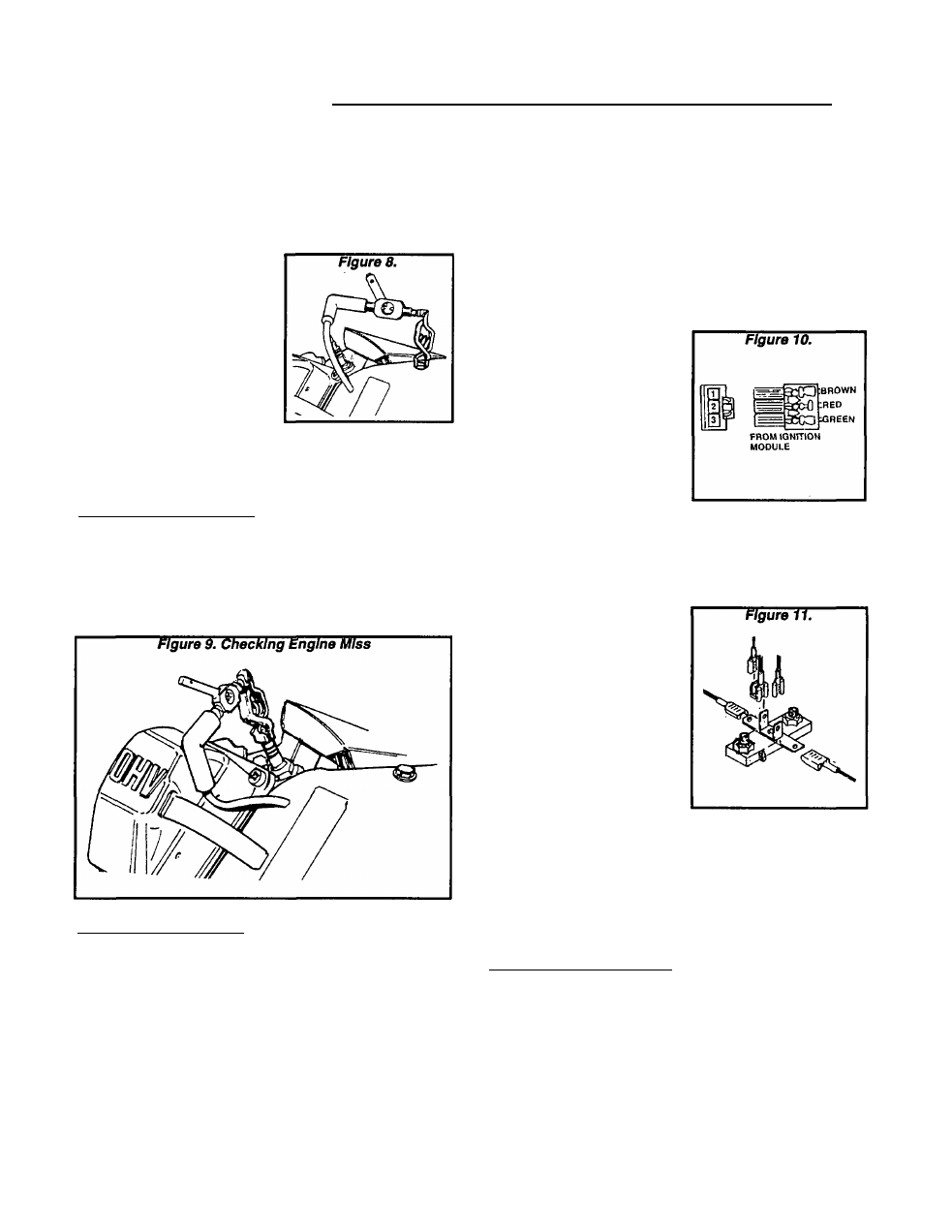

3. Connect the Spark Plug high tension lead to a

spark tester (Figure 8) and the spark tester clamp

to ground.

Page 6.4-3