General information, Description, Carburetor disassembiy – Generac Power Systems NP-40G User Manual

Page 59

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

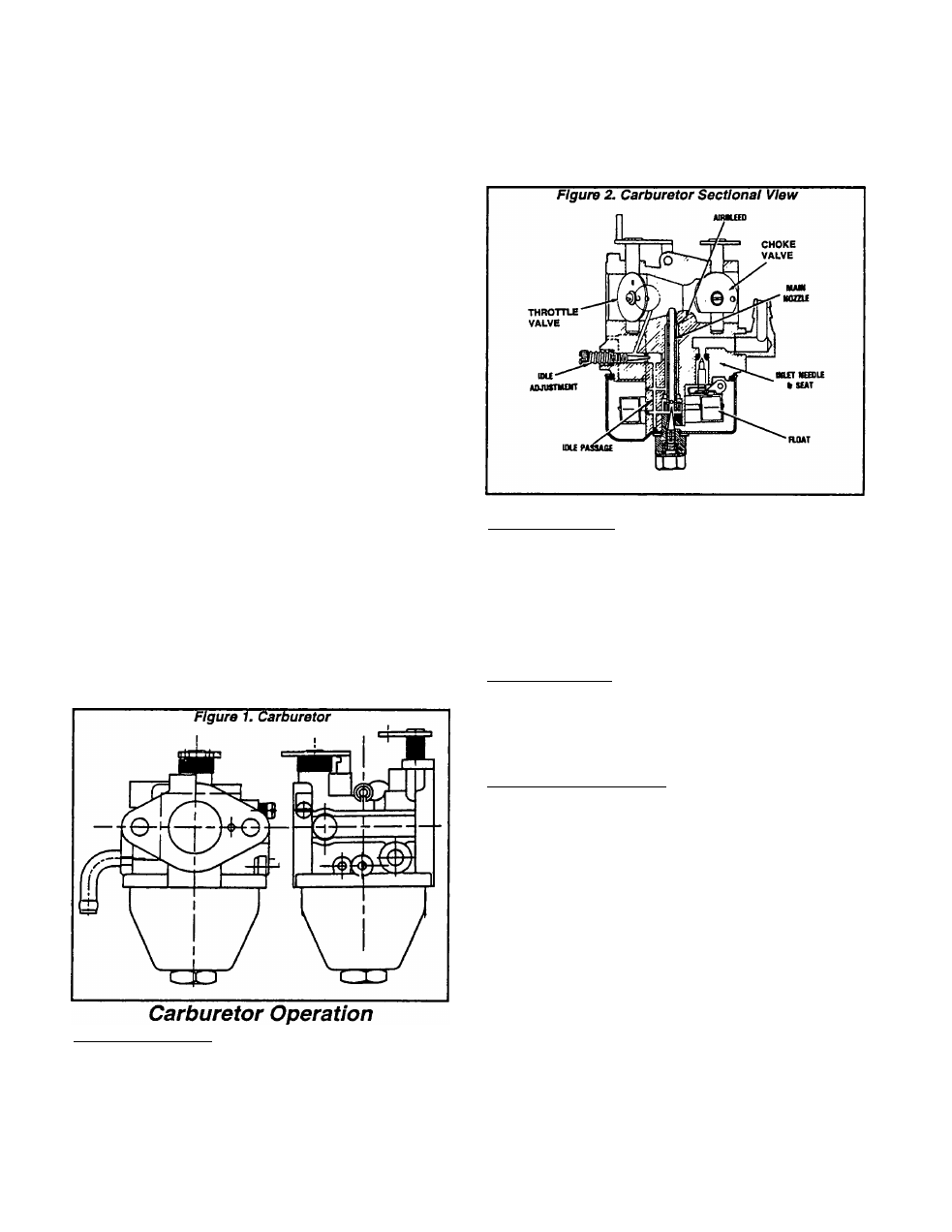

Section 3.4- CARBURETOR

General Information

Proper engine performance depends on the car-

buretion system. The use of clean, fresh gasoline

and a well-maintained air cleaner are extremely

important to proper operation, as well as engine

reliability and power.

Most causes of carburetion problems are related

to the use of stale, gummy fuel and the Ingestion

of dirt Before servicing the carburetor, be sure to

check for evidence of these conditions. Gasoline

that is left in the fuel lines for long periods can form

gum or varnish deposits that will adversely affect

carburetor operation.

NOTE:

A

commercial

fuel

stabilizer

(such

as

STABIL®) will minimize the formation of gum de

posits

durina

storage.

Add

the

stabilizer

to

the

gasoline In the fuel tank or In the storage container,

hollow

the

ratio

recommended

on

the

stabilizer

container. Run the engine for about 10 minutes

after adding stabilizer, to allow It to enter the car

buretor. "S

t

ABIL®“ I

s

a brand name fuel stabilizer

that can be purchased In most automotive repair

facilities or In lawn and garden centers.

Description

The carburetor used on GN-190 and GN-220 en

gines is a float type with fixed main jet. Carburetor

throttle position and engine speed are controlled

by an electric stepper motor. The stepper motor

moves the throttle in response to signals received

from a CCG circuit board. The circuit board senses

load voltage, establishes the correct engine speed

to obtain correct voltage and delivers an output

signal to the stepper motor. The stepper motor

adjusts the engine throttle to change engine speed

and establish correct output voltage.

FLOAT OPERATION;

A hollow plastic float maintains fuel level In the

float bowl. As fuel is used, the float moves down

ward to move an inlet needle valve off its seat.

When the needle valve moves off Its seat, fuel

can flow Into the bowl. As the fuel level rises, the

float moves upward to force the needle valve

against its seat and stop the flow into the bowl.

CHOKE POSITION:

The choke valve is closed to restrict the flow of

air Into the engine. As the engine cranks, air pres

sure in the cylinder is reduced. Since the air intake

passage is partially blocked by the choke valve,

fuel is drawn from the main nozzle and from the idle

discharge port. This creates the very rich fuel mix

ture required for starting a cold engine.

IDLE OPERATION:

The throttle valve is nearly closed to shut off the

fuel supply from all ports except the primary Idle

fuel discharge port. Engine suction then draws

fuel only from that port.

HIGH SPEED OPERATION;

The throttle valve is wide open. This allows a

large volume of air to pass through the carburetor

at a high velocity. The high velocity air flow past

the carburetor venturi results in a drop In air pres

sure at the venturi throat This reduceo air pressure

draws fuel through the main nozzle that opens into

the venturi which then mixes with the air in the air

passage.

Carburetor Disassembiy

See Figure 3, next page. The carburetor can be

disassembled as follows:

1. Remove the BOWL NUT (Item 3) and the FIBER

WASHER (Item 4). Then, remove the FLOAT BOWL

(Item 5).

2. Remove the FLOAT PIN (Item 6). Then, remove

the FLOAT (Item 7) and the INLET VALVE (Item 8).

Page 3.4-1