Test 11- test starter contactor, Test 13- check fuel supply, Test 12- test start-stop switch – Generac Power Systems NP-40G User Manual

Page 111: Test 14- check fuel filter, Test 15- check ignition spark, Test 16- check spark plug

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 7.2- ENGINE DC CONTROL SYSTEM

Test 11- Test Starter Contactor

DISCUSSION:

See "Starter Contactor" on Page 6.3-2. Replace

Starter Contactor If bad.

Test 13- Check Fuel Supply

DISCUSSION:

If the engine cranks but won’t start, don’t overlook

the obvious. The engine won’t start without fuel.

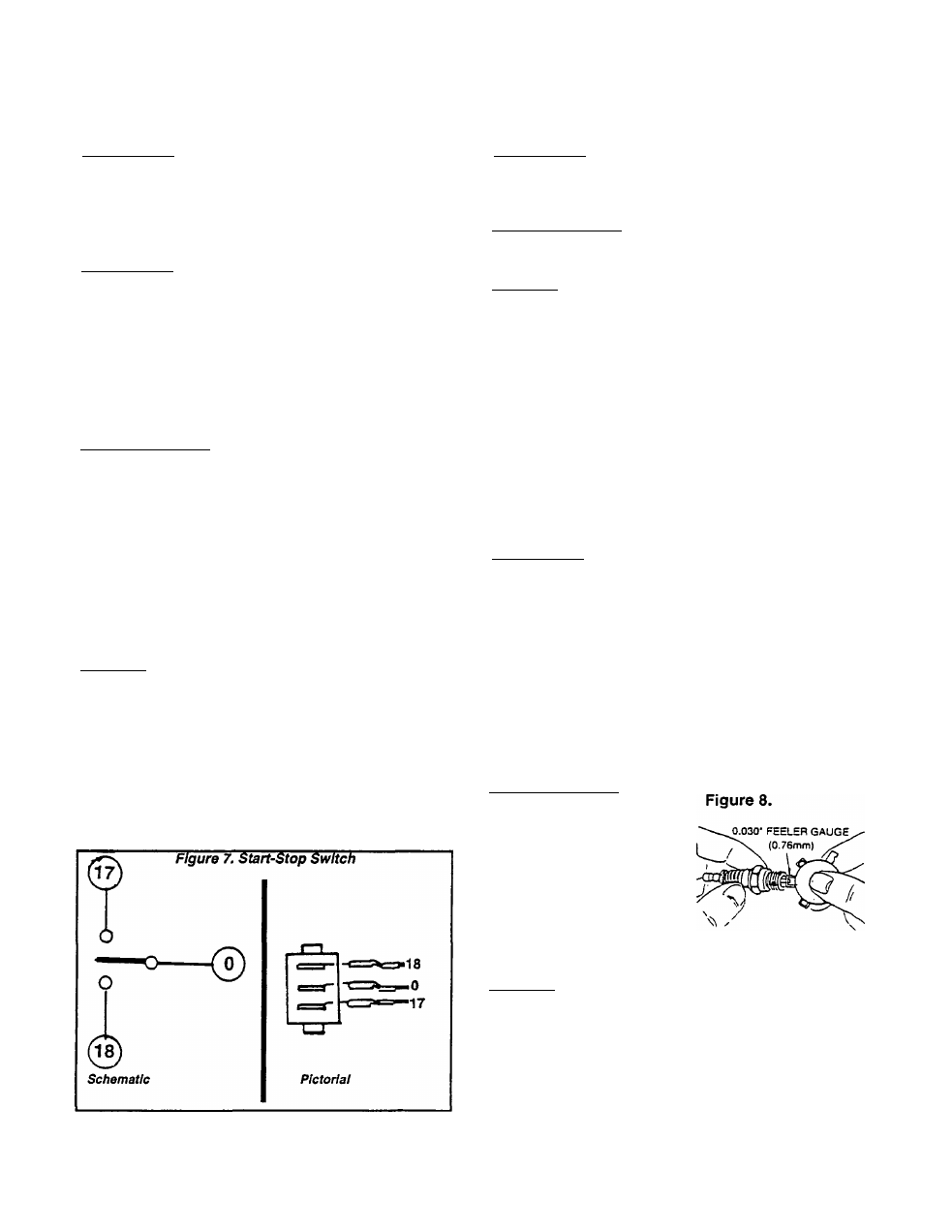

Test 12- Test Start-Stop Switch

DISCUSSION:

Engine cranking and startup are initiated when

the Start-Stop switch Is held at "START" to ground

Wire 17.

Engine shutdown is normally initiated when the

Start-Stop switch is set to "STOP" to ground Wire

18.

A defective switch can prevent normal startup or

normal shutdown.

TEST PROCEDURE:

Check fuel level.

RESULTS:

1. If fuel level is low, replenish fuel supply.

2. If fuel quantity is good, go to Test 14.

Test 14- Check Fuel Filter

Refer to Section 3.3.

TEST PROCEDURE:

1. Carefully Inspect Wire 0 (Ground) between the

Start-Stop switch and the ground terminal. Repair,

reconnect or replace the wire if necessary.

2. Disconnect Wire 17 from its terminal on the

Start-Stop switch. Connect Wire 17 to a clean frame

ground. The engine should crank.

3. Start the engine, using the Start-Stop switch or

by grounding Wire 17.

4. Stop the engine by holding the Start-Stop switch

at “STOP". If engine will not shut down with switch

at “STOP", ground Wire 18 to stop engine.

RESULTS:

1. if engine cranks when Wire 17 Is grounded, but

won’t crank with Start-Stop switch, replace the

Start-Stop switch.

2. if engine stops when Wire 18 is grounded but will

not shut down with Start-Stop switch, replace the

Switch.

3. If engine will not crank when Wire 17 is grounded,

replace the Engine Controller circuit board.

4. If engine will not stop when Wire 18 is grounded,

replace the Engine Controller circuit board.

Test 15- Check Ignition Spark

Refer to Section 6.4, "ENGINE IGNITION SYS

TEM".

Test 16- Check Spark Plug

DISCUSSION:

A badly fouled spark plug can prevent the engine

from starting. A defective spark plug may allow the

engine to be started, but rough operation or an

"engine miss" may be observed.

A commercially available spark tester can be

used to check for ignition spark. When the spark

tester is connected in series with the spark plug

and its high tension lead, the cause of an engine

miss can be narrowed down to either (a) the ignition

system, or (b) the spark plug or fuel system. Use

of the spark tester is discussed in Test 16.

TEST PROCEDURE:

Remove the spark plug.

Clean by scraping or wire

brushing and by using a

commercial solvent. DO

NOT BLAST CLEAN THE

PLUG. Set spark plug gap

to 0.030 inch (0.76mm). Re

place spark plug if badly

fouled,

if

ceramic

is

cracked, or if damaged.

RESULTS:

1. Clean and regap or replace spark plug as

necessary.

2. If spark plug is good but engine will not start,

go to Test 3.

3. If spark plug is good but engine misses or runs

rough,, go to Test 23.

Page 7.2-9