Battery (continued), Start-run-stop switch (sw1), Starter contactor – Generac Power Systems NP-40G User Manual

Page 89

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 6.3- ENGINE CRANKING SYSTEM

Battery (Continued)

TESTING A BATTERY (CONT’D);

If the battery State of Charge Is less than 100%,

use an automotive type battery charger to recharge

It to a 100% State of Charge.

2. Test for Condition:

a. If the difference In specific gravity between the

highest and lowest reading cell is greater than

0.050 (50 points), the battery is nearing the end

of Its userul life and should be replaced.

b. However, If the highest reading cell is less than

1.230, recharge thebattery and repeat the test.

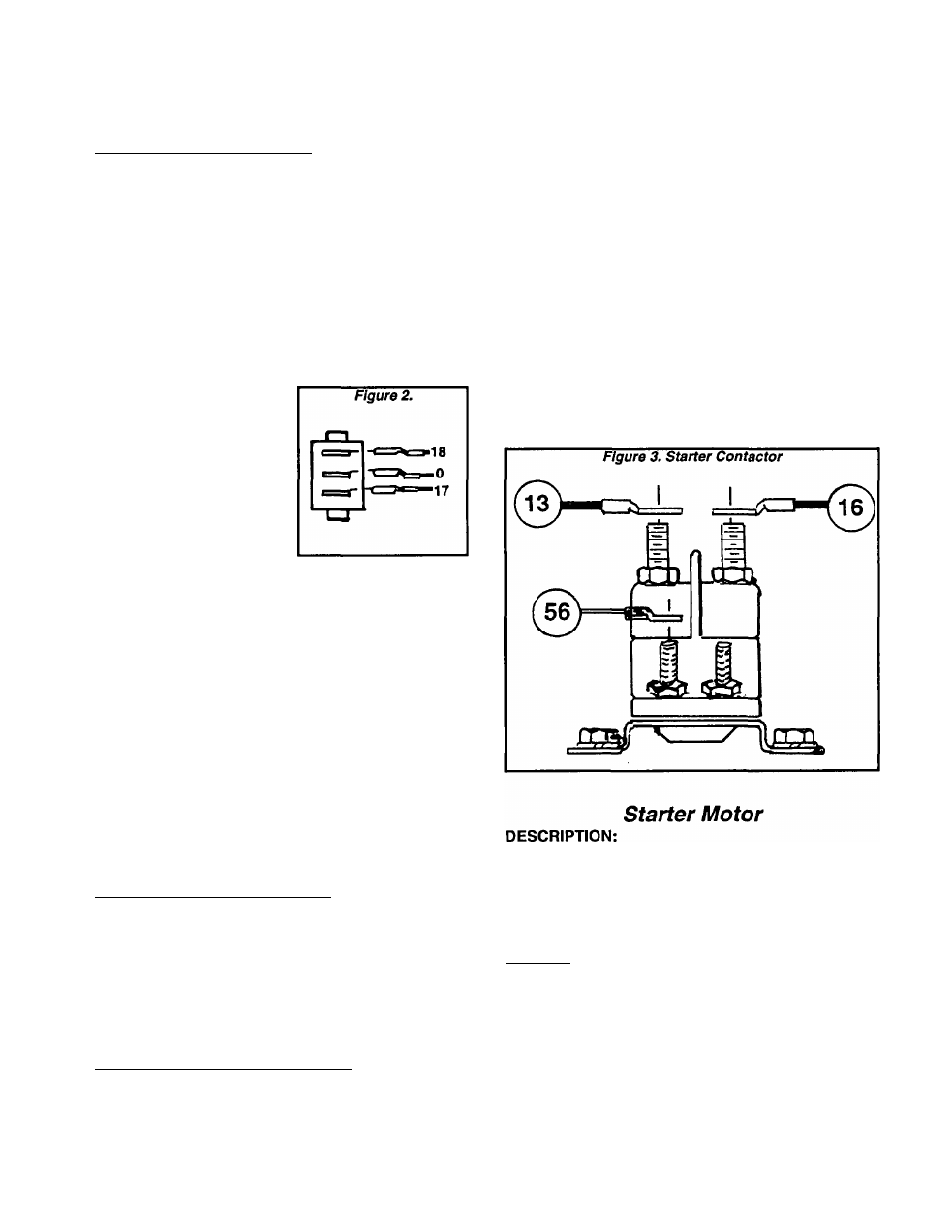

Start-Run-Stop Switch (SW1)

Wires 17 and 18 connect

to the two outer terminals

of the switch. Wire 0

(ground) connects to the

switch center terminal.

The switch can be tested

using a volt-ohm-milliam-

meter (VOM) as follows:

1. Set the VOM to Its" Rxl “ scale and zero the meter.

2. Connect the VOM test leads across the Wire 17

terminal and the center (Wire 0) terminals.

a. Hold the switch at "START" and the VOM

should indicate "continuity".

b. Hold switch at "STOP" and meter should read

"infinity".

3. Now, connect the meter test leads across the

center and Wire 18 terminals.

a. With switch at “START" VOM should Indicate

"infinity".

b. With switch at "STOP", meter should read

"continuity".

Replace the switch If It is defective.

Starter Contactor

WIRE AND CABLE CONNECTIONS:

The red (positive) battery cable connects to one

of the starter contactor’s large terminal lugs. The

unit’s 15 amp fuse also attaches to this lug, via Wire

13.

The starter motor (SM) cable (16) attaches to the

second terminal lug.

Wire 56, from the engine controller circuit board,

attaches to one of the small contactor terminals.

TESTING THE STARTER CONTACTOR:

To test the installed Starter Contactor, proceed

as follows:

1. Set a volt-ohm-milliammeter (VOM) to read bat

tery voltage (12 VDC).

2. Connect the VOM test leads across the Wire 56

terminal of the Contactor and frame ground. The

meter should Indicate "zero" volts.

3. Hold the Start-Run-Stop switch at "START" and

the VOM should read battery voltage and the Con

tactor should energize. After reading the voltage,

release the switch. If battery voltage Is NOT indi

cated, a problem exists elsewehere in the circuit

4. Connect the VOM test leads across the Wire 16

terminal lug and frame ground.

a. Hold the Start-Run-Stop switch at “START".

The Contactor should actuate and the meter

should Indicate battery voltage.

b. If battery voltage Is not Indicated, replace the

Starter Contactor.

c. If battery voltage Is Indicated but engine does

not crank, check the Starter Motor and its cable.

The Starter Motor is a 12 volts negative ground

type. It Is capable of operating on heavy duty bat

tery Input at temperatures as low as -30 F. without

any significant change in performance. Its pinion

is a 10-tooth type having a 20’ pressure angle.

TESTING:

Connect the test leads of a VOM across the

Starter Motor terminal and case. Hold the Start-

Run-Stop switch at "START". The VOM should read

battery voltage and the Starter Motor should turn.

If VOM reads 12 volts DC and the Motor does not

turn, the Motor is probably defective. Remove the

Motor and test with a 12 volts DC power source.

Replace the Starter Motor if defective.

Page 6.3-2