Camshaft inspection (continued), Crankshaft inspection – Generac Power Systems NP-40G User Manual

Page 49

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 2.4- CRANKSHAFT AND CAMSHAFT

Camshaft Inspection (Continued)

The following should be measured carefully to check

for wear:

MAIN CAMSHAFT BEARING DIAMETER

(FLYWHEEL END)

DESIGN DIAMETER: 1.022-1.023 Inch (25.96-25.98mm)

WEAR LIMIT: 1.020 Inch (25.91mm) Minimum

MAIN CAMSHAFT BEARING DIAMETER

(PTO END) GN-190 ONLY

DESIGN DIAMCTER: 1.022-1.023 Inch (25.96-25.98mm)

WEAR LIMIT: 1.020 Inch (25.91mm) Minimum

MAIN CAMSHAFT BEARING DIAMETER

(PTO END) GN-220 ONLY

DESIGN DIAMETER: 1.297-1.298 Inch (32.96-32.98mm)

WEAR LIMIT: 1.295 Inch (32.89mm) Minimum

CAMSHAFT BEARING BORE IN CRANKCASE

DESIGN DIAMETER: 1.024-1.025 Inch (26.00-26.03mm)

WEAR LIMIT: 1.026 Inch (26.06mm) Maximum

CAMSHAFT BEARING BORE IN CRANKCASE COVER

DESIGN DIAMETER: 1.299-1.300 inch (33.00-33.03mm)

WEAR LIMIT: 1.302 Inch (33.06mm) Maximum

CAM LIFT

DESIGN LIFT: 0.210-0.212 Inch (5.34-5.38mm)

WEAR LIMIT: 0.206 Inch (5.24mm) Minimum

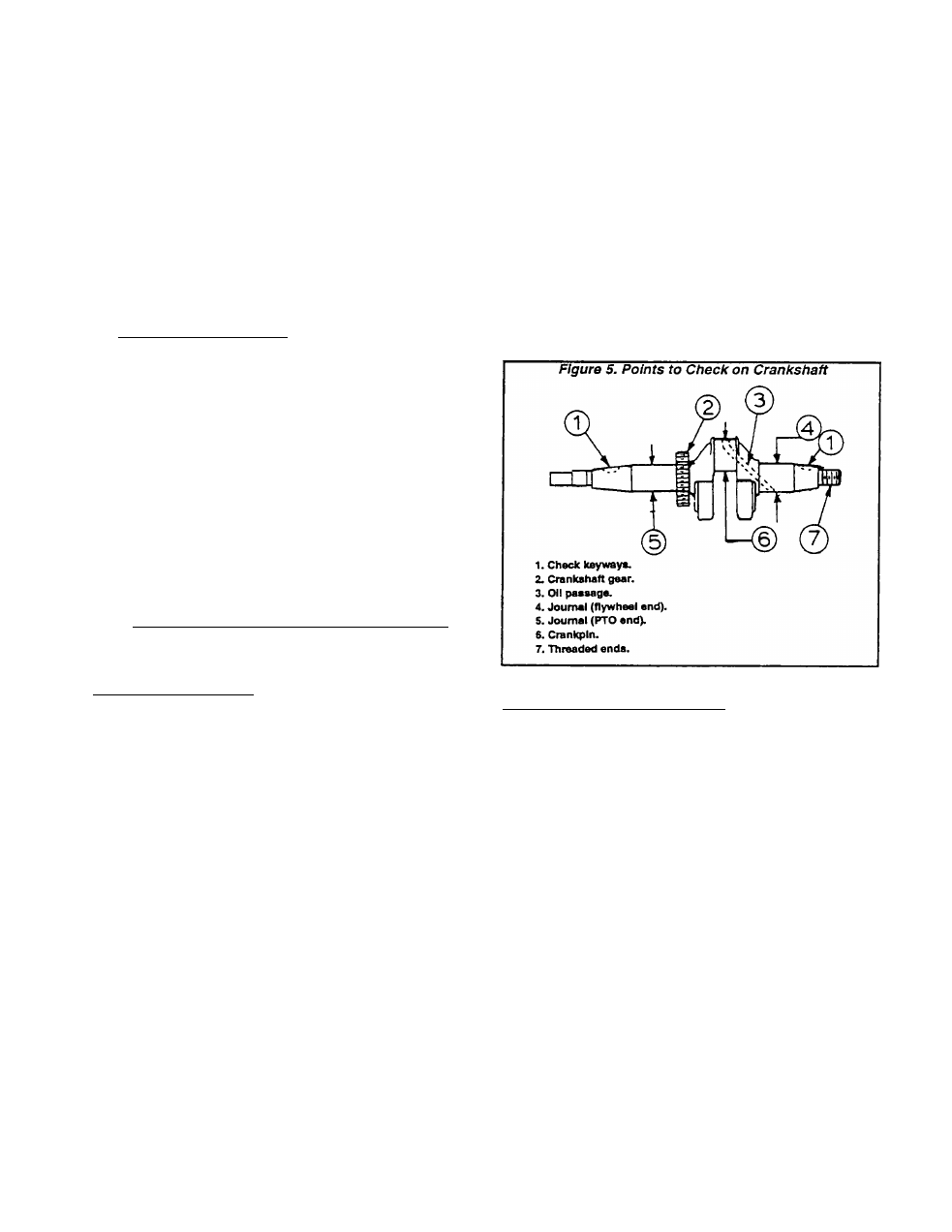

Crankshaft Inspection:

CRANKSHAFT PROPER:

Use a commercial solvent to clean the crankshaft.

After cleaning, Inspect the crankshaft as follows:

□ Inspect keyways in crankshaft, make sure they are

not worn or spread. Remove burrs from edges of

keyway, to prevent scratching the bearing.

D

Inspect timing gear teeth for chipping or cracking. If

the timing gear Is damaged, the crankshaft assembly

must be replaced.

G

Inspect the crankpin for damage, nicks, scratches,

etc. Small nicks and scratches may be polished out

using fine emery cloth. ALL EMERY RESIDUE MUST

BE REMOVED. Use a solvent (such as kerosene) to

remove emery residue.

D Carefully measure the outside diameter (O.D.) of the

crankpin, crankshaft journal at flywheel end, and

crankshaft journal at PTO end. Replace the crank

shaft if it is worn smaller than the stated limits.

NOTE: DO NOT regrInd the crankpin to any smaller

diameter. Undersize connecting rods are NOT

available for the GN-190 or GN-220 engines.

G

Inspect oil passage. Use a length of wire to make

sure it Is open. Inspect threaded ends of crankshaft.

CRANKPIN OUTSIDE DIAMETER

DESIGN DIAMETER: 1.180-1.181 INCH (29.99-30.01 MM)

WEAR LIMIT: 1.179 inch (29.96mm) Minimum

CRANKSHAFT BEARING JOURNAL (FLYWHEEL END)

DESIGN DIAMETER: 1.102-1.103 Inch (28.000-

28.012mm)

WEAR LIMIT: 1.100 inch (27.95mm) Minimum

CRANKSHAFT BEARING JOURNAL (PTO END)

DESIGN DIAMETER: 1.102-1.103 inch (28.000-

28.012mm)

WEAR LIMIT: 1.186 inch (27.95mm) Minimum

CRANKSHAFT SLEEVE BEARING:

A sleeve bearing (Figure 6) Is pressed into the crank

shaft bore of the crankcase. A bearing is NOT provided

for the crankshaft bore in the crankcase cover.

Inspect the sleeve bearing In the crankcase for dam

age. Measure the inside diameter (I.D.) of the sleeve

bearing. Replace any sleeve bearing that Is worn exces

sively. Press out the old bearing, press a new bearing

into place.

CRANKSHAFT SLEEVE BEARING

DESIGN DIAMETER: 1.104-1.106 inch (28.044-

28.099mm)

WEAR LIMIT: 1.107 inch (28.129mm) Maximum

Check the crankshaft bearing bore in the crankcase

cover. If limits are exceeded, replace the crankcase

cover.

CRANKSHAFT BEARING BORE IN CRANKCASE

COVER

DESIGN DIAMETER: 1.104-1.105 inch (28.040-

28.065mm)

WEAR LIMIT: 1.106 inch (28.092mm) Maximum

Page 2.4-2