Piston rings, Section 2,3- piston, rings, connecting rod, Piston (continued) – Generac Power Systems NP-40G User Manual

Page 45

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Piston Rings

Section 2,3- PISTON, RINGS, CONNECTING ROD

Piston (Continued)

CHECK PISTON FOR WEAR (CONT’D):

4. Check Wrist Pin for Wear:- Measure the outside diam

eter of the wrist pin. Also measure the inside diameter of

the wrist pin bore in the piston and In the connecting rod.

Also check wrist pin length. Replace any component that

is worn excessively.

GENERAL:

The following rules pertaining to piston rings must

always be complied with:

□

□

WRIST PIN OUTSIDE DIAMETER (GN190 & GN220)

DESIGN DIAMETER: 0.708-0.709 Inch (17.989-

18.000mm)

WEAR UMIT: 0.707 Inch (17.969mm) Minimum

WRIST PIN LENGTH (GN190 & GN220)

DESIGN LENGTH: 2.196-2.213 Inch (55.8-56.2mm)

WEAR LIMIT: 2.193 inch (55.7mm) Minimum

WRIST PIN BORE IN PISTON (GN190 & GN220)

DESIGN DIAMETER: 0.708-0.709 inch (18.000-

18.011mm)

WEAR LIMIT: 0.710 Inch (18.026mm) Maximum

CONNECTING ROD SMALL END I.D. (GN190 & GN220)

DESIGN DIAMETER: 0.709-0.710 inch (18.02-18.03mm)

WEAR UMIT: 0.711 inch (18.05mm) Maximum

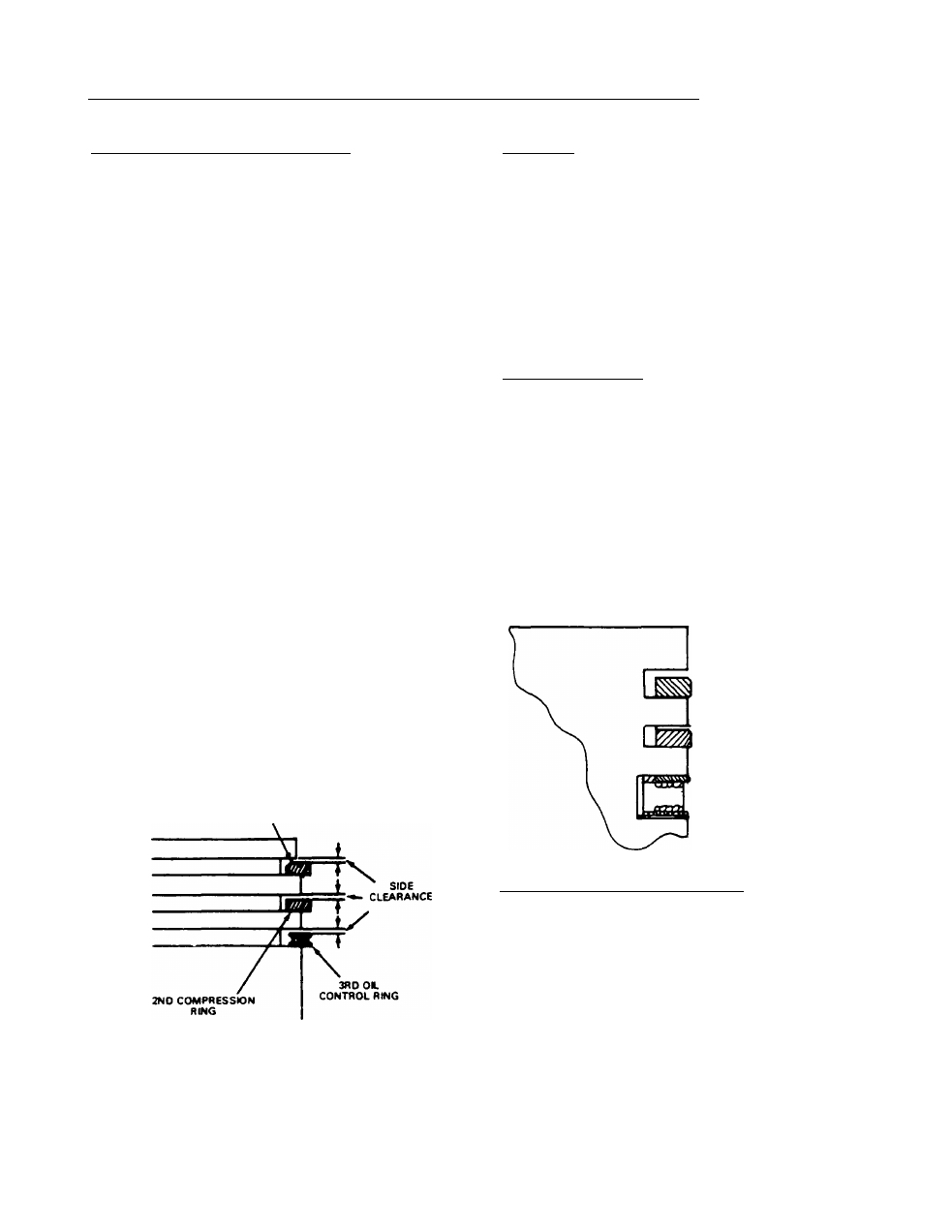

5. Ring to Groove Side Clearance:- Clean carbon from

piston ring groov js. Install new rings. Use a feeler gauge

to measure the side clearance between the rings and ring

grooves. If ring-to-groove side clearance exceeds the

stated limits, replace the piston.

RING TO GROOVE SIDE CLEARANCE (GN190 &

GN220)

0.0004-0.0014 inch (0.012-0.034mm)

Figure 6. Ring to Groove Side Clearance

1ST COMPRESSION RING

Figure 7. Ring Locations in Piston Grooves

TOP COMPRESSION RING

EITHER SIDE UP

2ND COMPRESSION RING

CHAMFER FACES UP

OIL CONTROL RING

EITHER SIDE UP

CHECKING PISTON RING END GAP:

To check piston rings end gap, proceed as follows

(see Figure 8):

1. Locate a point inside the cylinder that Is 2.75 inches

(70mm) down from top of cylinder. This Is approximately

half-way down.

2. Place the ring into the cylinder. Use the piston to push

the ring squarely into the cylinder to the proper depth.

3. Use a feeler gauge to measure the ring end gap. If end

gap is excessive, rebore the cylinder to take oversize

parts.

TOP RING END GAP (GN190

&

GN220)

DESIGN GAP: 0.005-0.016 inch (0.15-0.40mm)

WEAR LIMIT: 0.024 inch (0.60mm) Maximum

Always replace piston rings in sets.

When removing rings, use a ring expander to pre

vent breakage. Do not spread the rings too far or they

will break.

D

When installing the piston into the cylinder, use a

ring compressor. This will prevent ring brteakage

and/or cylinder damage.

n When installing new rings, deglaze the cylinder wall

with a commercially available deglazing tool.

RING DESCRIPTION:

A piston ring SET consists of (a) a top compression

ring, (b) a second compression ring, and (c) an oil ring

assembly. When installing rings, pay close attention to

the following:

G

The OIL RING is a 3-piece assembly which consists

of two oil rails and an oil spacer ring. Oil rails have

a rounded face and can be Installed with either side

_ up-

□ The second compression ring has an inside chamfer

which must face UP when installing the ring.

G

The top compression ring has a barrel-shaped face

and can be Installed with either side up.

Page 2.3-2