Oil sump, Oil filter support – Generac Power Systems NP-40G User Manual

Page 79

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 5.1- ENGINE OIL SYSTEM

The breather serves to maintain a partial vacuum

In the engine crankcase, to prevent oil from being

forced past oil seals, gaskets or rings.

See Figure 6. A reed type breather valve permits

excess pressure to be vented out of the crankcase

and to atmosphere through a breather tube. A

breather retainer limits the movement of the

breather valve. Two small oil return holes In the

breather cup allow condensed oil vapors to drain

back to the crankcase. A "steel wool" type breather

separator separates the breather cup from the

breather cover and breather tube opening.

Figure 6, Breather Assembly

TO AIR

CLEANER

BASE

BREATHER

VALVE

BREATHER

BAFFLE CUP

— M6 BOLT

- BREATHER

COVER

GASKET

INSPECTION:

Remove the breather hose. Inspect It for cracks,

damage, hardening. Replace, If necessary.

Clean the breather cover and breather cup In

commercial solvent. Check that the two small drain

holes In the breahtre cup are open; open with a

length of wire. If necessary.

Inspect the rivets that retain the reed type

breather valve, make sure they are tight. Also

check that the valve seats flat on the breather cup

around the entire surface of the valve.

Oil Sump

DESCRIPTION:

The die cast aluminum oil sump Is retained to the

crankcase with six (6) flanged head bolts. Install a

new gasket between the oil sump and crankcase

each time the oil sump Is removed.

Bores are provided In the oil sump for fa) oil

pump rotors and camshaft, (b) crankshaft, (c) gov

ernor gear assembly, (d) oil pickup. Cored oil pas

sages are provided from the pickup to the pump

and from the pump to the crankshaft bore.

INSPECTION:

Clean the oil sump and blow dry with com

pressed air. Use compressed air to blow out all oil

passages. Inspect the sump for cracks, damaae,

etc. Check the following bores In the oil sump Tor

wear:

CRANKSHAFT BEARING BORE DIAMETER

GN-190 ENGINE

DESIGN DIAMETER: 1.103-1.105 Inch (28.030-

28.058mm)

WEAR LIMIT:

1.106 Inch (28.088mm) Maximum

CRANKSHAFT BEARING BORE DIAMETER

GN-220 ENGINE

DESIGN DIAMETER: 1.104-1.105 Inch (28.040-

28.065mm)

WEAR LIMIT: 1.106 Inch (28.092mm) Maximum

CAMSHAFT BEARING BORE DIAMETER

GN-190 & GN-220 ENGINE

DESIGN DIAMETER: 1.299-1.300 Inch (33.00-33.03mm)

WEAR LIMIT: 1.302 Inch (33.06mm) Maximum

OIL PUMP INNER ROTOR SHAFT DIAMETER

GN-190 & GN-220 ENGINE

DESIGN DIAMETER: 0.353-0.354 Inch (8.969-8.987mm)

WEAR LIMIT: 0.352 Inch (8.949mm) Minimum

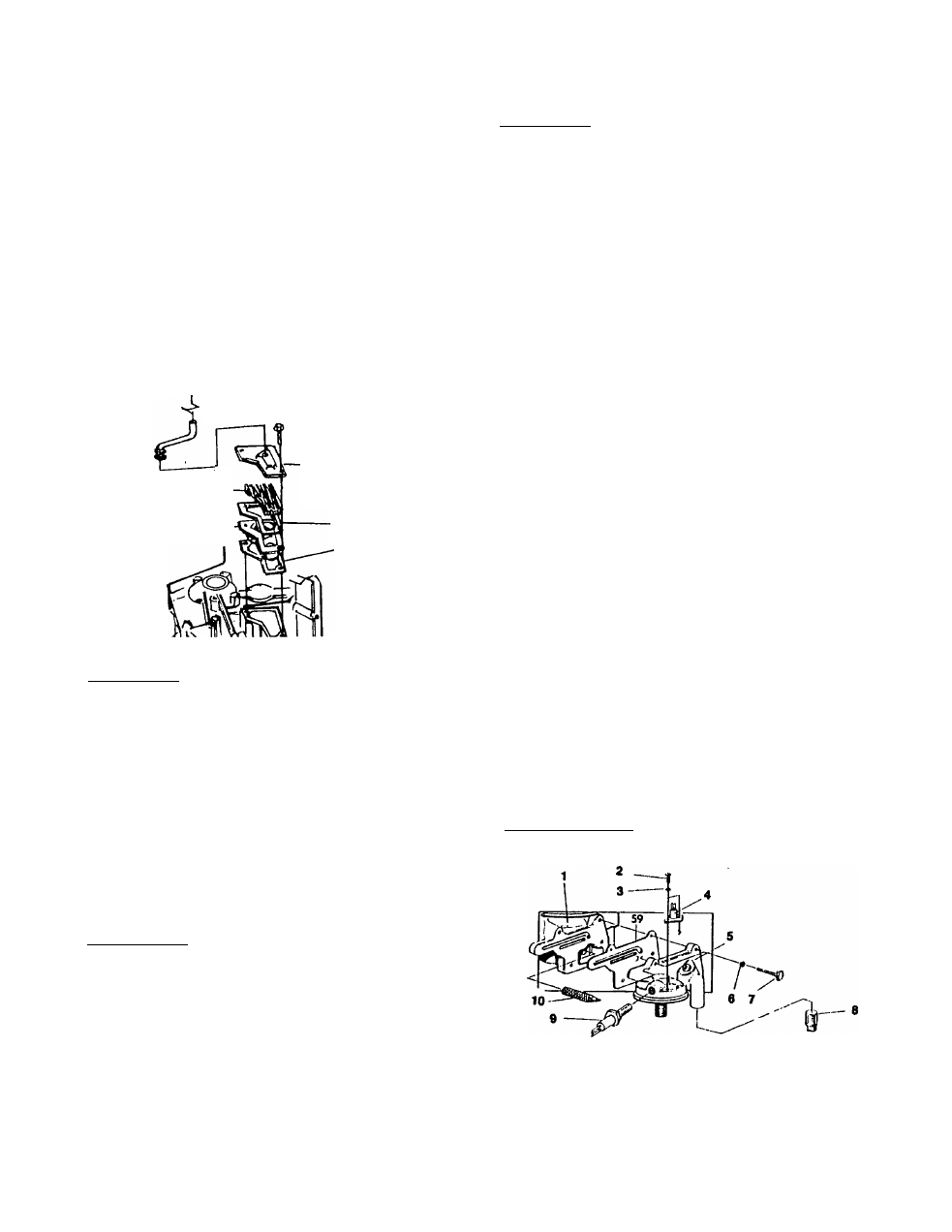

Oil Filter Support

An oil filter support and its gasket are retained to

the oil sump by four (4) M6-1.00 bolt.

A threaded bore Is provided In the support for a

low oil pressure switch. This switch will protect the

engine against damaging low oil pressure by shut

ting the engine down automatically If oil pressure

should drop below a pre-set low limit.

A high oil temperature switch Is retained to the

support by two (2) MS screwqs and lockwashers.

This thermal sensor will protect the engine against

damaging high temperature conditions through au-

tomatlc shutdown.__________________________

Figure 7. Oil Filter Support

1. Oil Sump 5. Filter Support

2 MS Scraw 6. Lockwasher

3. Lockwasher 7. Screw

4. Oil Temp. Switch

8. Pipe Plug

9. Olf Press. Switch

10.011 Pickup

Screen

Page 5.1-3