Compression release mechanism, Installing the crankshaft, Installing the camshaft – Generac Power Systems NP-40G User Manual

Page 50

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 2.4- CRANKSHAFT AND CAMSHAFT

Compression Release Mechanism

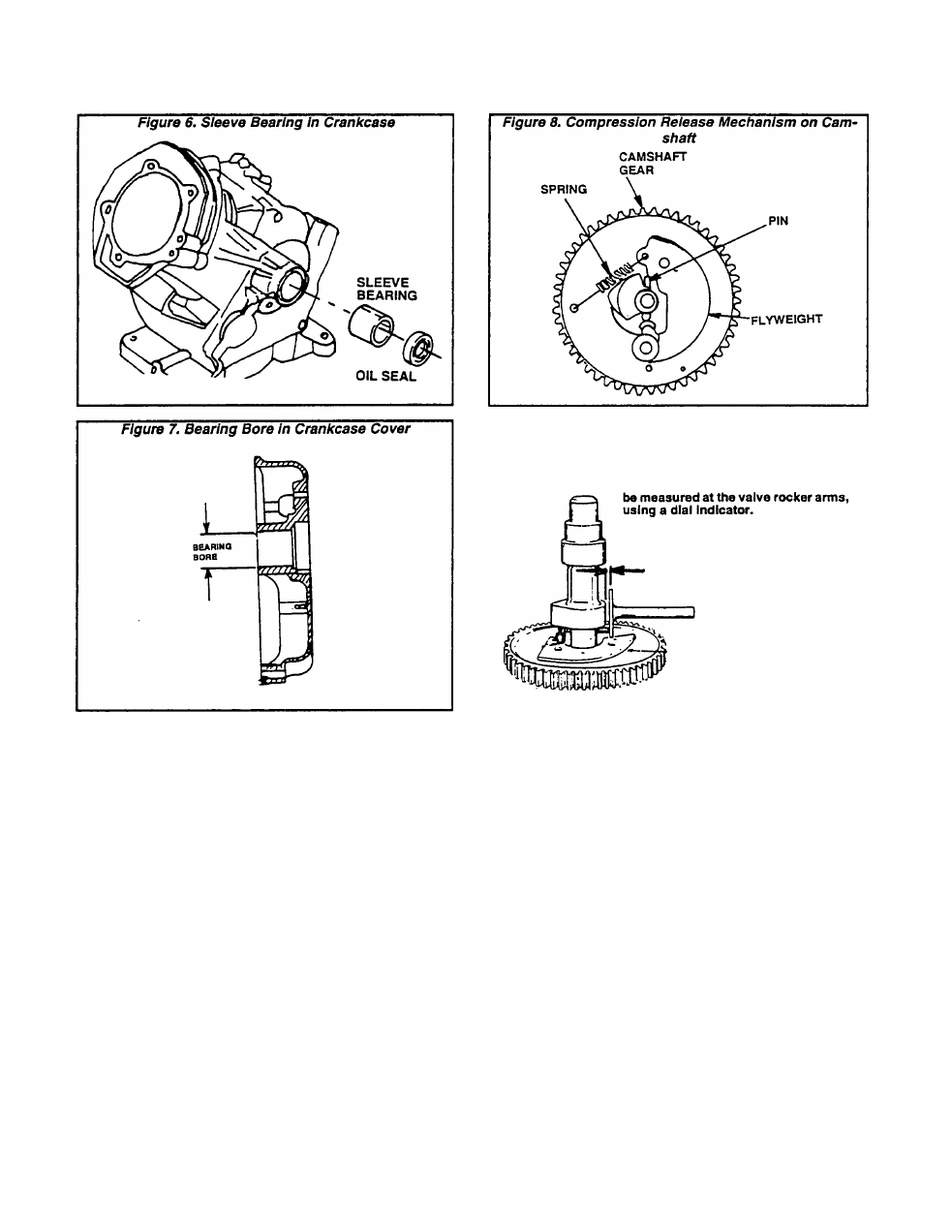

A mechanical compression release Is provided on the

camshaft. See Rgure 8. A PIN extends over the cam lobe.

This PIN pushes on the tappet, to lift the valve and relieve

compression for easier cranking. When the engine

starts, centrifugal force moves the FLYWEIGHT outward

against SPRING force. The PIN will then drop back and

allow the engine to run at full compression.

Measure the amount of compression release lift at the

tappet (Rgure 9).

COMPRESSION RELEASE LIFT FOR GN-190 ENGINE

(MEASURED AT TAPPET)

DESIGN LIFT: 0.027-0.055 Inch (0.70-1.40mm)

WEAR LIMIT: 0.023 Inch (0.60mm) Minimum

COMPRESSION RELEASE LIFT FOR GN-220 ENGINE

(MEASURED AT TAPPET)

DESIGN LIFT: 0.020-0.047 Inch (0.50-1.20mm)

WEAR LIMIT: 0.016 Inch (d.406mm) Minimum

Figure 9. Measuring Compression Release Lift

Compression relief lift can also

Installing the Crankshaft

Before Installing the crankshaft, lubricate all bearing

surfaces with engine oil. Use oil seal protectors, to pre

vent damage to seals during installation. Install the

crankshaft as follows:

1. Lubricate all bearing surfaces with engine oil.

2. Install the valve tappets.

3. Support both ends of the crankshaft and carefully

Install Into the crankcase.

4. Rotate the crankshaft until the timing mark (Figure

10) is toward the cam gear side of the crankcase.

Installing the Camshaft

Apply engine oil to the camshaft main bearing and to

bearing bore In crankcase. Carefully install the camshaft

Into the crankcase camshaft bore.

Hold the tappets out of the way during Installation.

Align timing mark on camshaft gear with timing mark on

crankshaft gear (piston will be at top dead center). See

Figure 11.

Page 2.4-3