Introduction, Cycle engine theory – Generac Power Systems NP-40G User Manual

Page 34

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 2.1- GENERAL INFORMATION

Introduction

The engine used on Series NP-30G and NP-40G recre

ational vehicle AC generators Is a Generac Series GN190

or GN220, vertical shaft, single cylinder, overhead valve

type.

These engines are not equipped with a mechanical

engine governor. Instead, variable engine speeds are

controlled by a computer circuit board. The circuit board

signals a stepper motor to move the carburetor throttle

linkage.

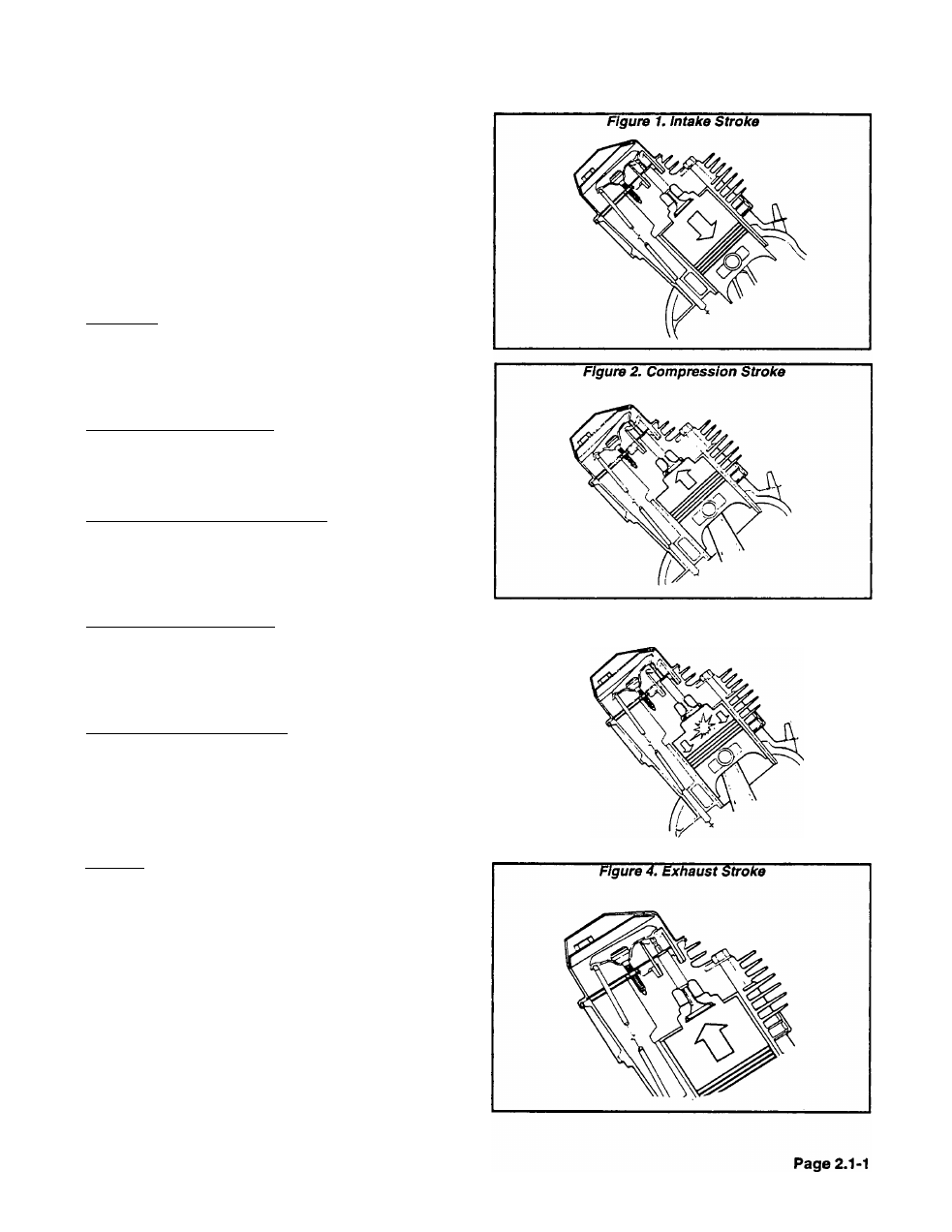

4-Cycle Engine Theory

GENERAL;

Series GN190 and GN220 engines require four (4)

strokes or cycles to complete one power cycle. This is

often called the ''4-stroke, 5-event" cycle. The 4 strokes

and 5 events that occur are (1) Intake, (2) compression,

(3) Ignition, (4) power and (5) exhaust

INTAKE STROKE (Figure 1):

The Intake valve is open. The exhaust valve Is closed.

The piston travels downward, creating a suction which

draws the air-fuel mixture from the carburetor Into the

cylinder and Just above the piston.

COMPRESSION STROKE (Figure 2):

As the piston reaches bottom dead center (BOC), the

Intake valve closes. The exhaust valve remains closed,

as well. The piston starts to move outward in the cylinder.

Since both valves are closed, the air-fuel mixture In the

cylinder Is compressed.

POWER STROKE (Figure 3);

Both valves remain closed. At some point before the

piston reached top dead center (TDC), the spark plug

fires to ignite the fuel-air mixture. The piston moves to

its top dead center position and the burning, expanding

gases of combustion force the piston downward.

EXHAUST STROKE (Figure 4):

The expanding gases of combustion force the piston

downward to its bottom dead center (BOC) position. The

exhaust valve then opens, as the piston starts its move

ment toward top dead center (TDC). Piston movement

then forces the exhaust gases out through the open

exhaust valve. The 4-stroke cycle of events then starts

over again.

TIMING;

Valve timing and Ignition timing must be precisely

controlled If the engine Is to operate properly and effi

ciently. Intake and exhaust valves must open and close

In a precise timed sequence If the four strokes are to

occur. Ignition must occur at exactly the correct piston

position, just prior to the start of the power stroke.

Timing of valve opening and closing, as well as of spark

occurence. Is given in relation to the piston position and

the degrees of crankshaft rotation.

Ignition Is timed to occur several degrees before top

dead center (TDC) of the piston, to allow time for the

air-fuel mixture to ignite and start to bum before the

piston reaches top dead center

There must be no leakage past the valves in their

closed position or compression will not develop. Like

wise, there must be no leakage past the piston-

Figure 3. Power Stroke