Introduction – Generac Power Systems NP-40G User Manual

Page 88

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

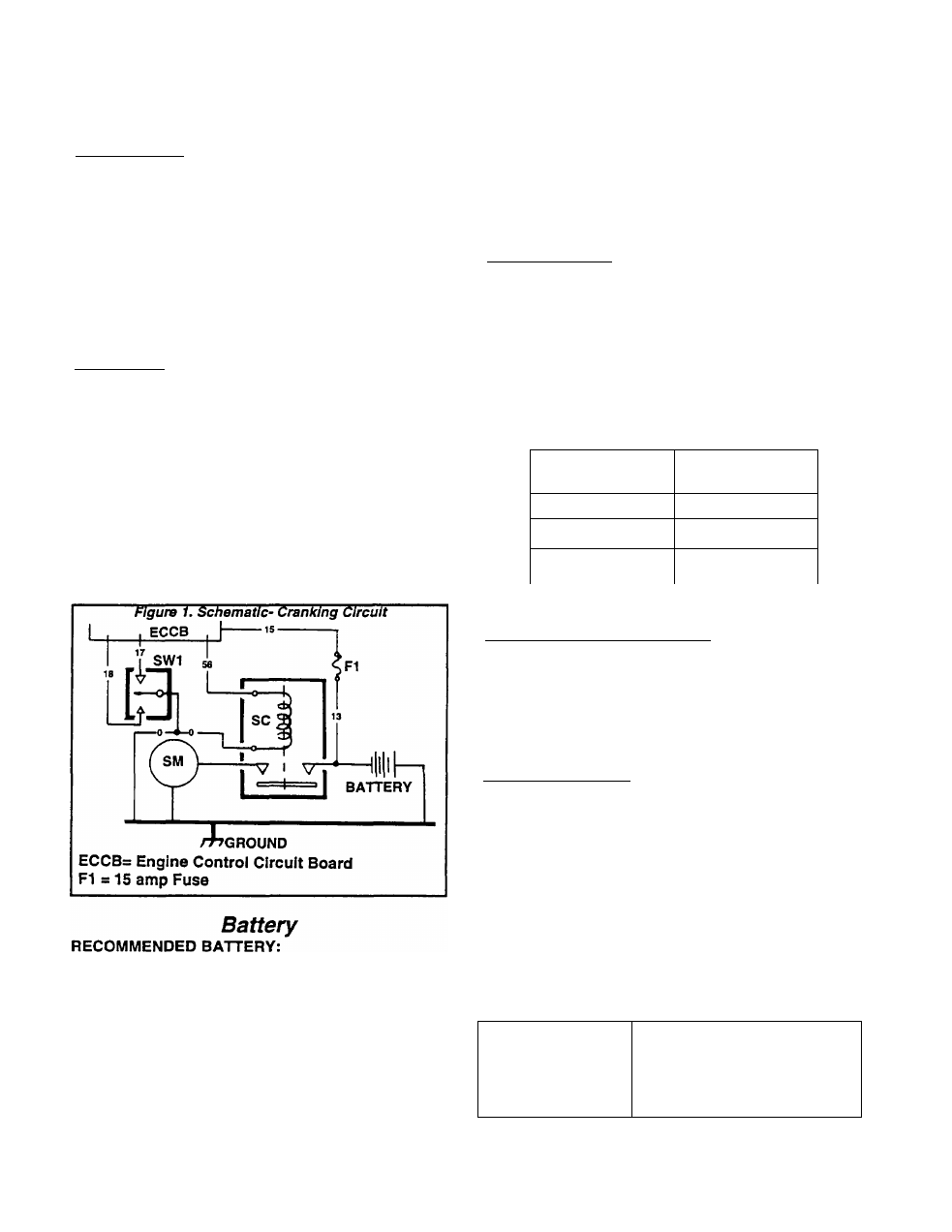

Section 6.3- ENGINE CRANKING SYSTEM

Introduction

COMPONENTS:

The enqine cranking wstem Is shown schemat

ically in Figure 1, below. The system consists of the

following components:

n A 12 volts Battery.

□ A Start-Run-Stop Switch (SW1).

□ A Starter Contactor (SC),

n A Starter Motor (SM).

□ Engine Controller Circuit Board.

□ Interconnecting wires.

OPERATION:

1. Holding the Start-Run-Stop switch (SW1) at

"START* connects Wire 17 from the Engine Con

troller board to frame ground.

a. Engine Controller board action energizes a

crank relay on the board.

b. Closure of the crank relay’s contacts delivers

12 VDC to Wire 56 and to a Starter Contactor (SC).

The Starter Contactor (SC) energizes and its con

tacts close.

2. Closure of the the Starter Contractor (SC) con

tacts delivers battery voltage to the Starter Motor

(SM). The Motor energizes and the engine is

cranked.

The battery is generally supplied by the cus

tomer. Recommended is a battery that meets the

following requirements:

□ Use a 12 VDC automotive type storage battery.

□ For prevailing ambient temperatures above 32*

F. (0* C.), use a battery rated at 70 amp-hours

and capable of delivering 360 cold-cranking

amperes.

□ For prevailing ambient temperatures below 32*

F. (0* C.), use a battery rated 95 amp-hours and

capable of delivering 450 cold-cranking am

peres.

BATTERY CABLES:

Battery cables should be as short as possible

and of adequate diameter. Cables that are too long

or too small in diameter can result In voltage drop.

The voltage drop between battery terminals and the

connection point at generator should not exceed

0.121 volts per 100 amperes of cranking current.

The cables should be carefully selected based on

(a) cable length and (b) prevailing ambient temper

atures. Generally, the longer the cable and the

colder the ambient temperature, the larger the re

quired cable size. The following chart applies:

CABLE LENGTH

Feet (Meters)

CABLE SIZE

0 to 10(0 to 3)

2*

11 to 15(3.4-4.5

0

16 to 20 (4.5 to 6)

000

For warm weather use No. 2 cable up to 20 feet

BATTERY CABLE CONNECTIONS:

1. Connect the cable from the large Starter Contac

tor (SC) lug to the battery post Indicated by a

POSITIVE, POS or (+).

*2:'Connect the cable from Its FRAME GROUND

connection to the battery post indicated by a NEG

ATIVE, NEG or (-).

TESTING A BATTERY:

The best method of testing a battery Is with an

automotive type battery hydrometer. Some “Main

tenance Free" batteries cannot be tested with a

hydrometer.

Most batteries can be tested for both STATE OF

CHARGE and CONDITION as follows:

1. Test for State of Charge:-

a. Follow the hydrometer manufacturer's instruc

tions carefully. Test the specific gravity of the

fluid in all battery cells.

b. If the hydrometer does not have a "Percentage

of Charge" scale, compare the readings obtained

with the following:

SPECIRC GRAVITY

PERCENTAGE OF CHARGE

1.260

100%

1.230

75%

1.200

50%

1.170

25%

Page 6.3-1