Oil pump (continued), Crankshaft oil seals, Pressure relief valve – Generac Power Systems NP-40G User Manual

Page 78: Breather assembly

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 5.1- ENGINE OIL SYSTEM

Oil Pump (Continued)

INSPECTION (CONT’D):

Inspect the outer drive pins on the camshaft

Look for breakage, bending, other damage. These

are roll pins which can be removed and replaced.

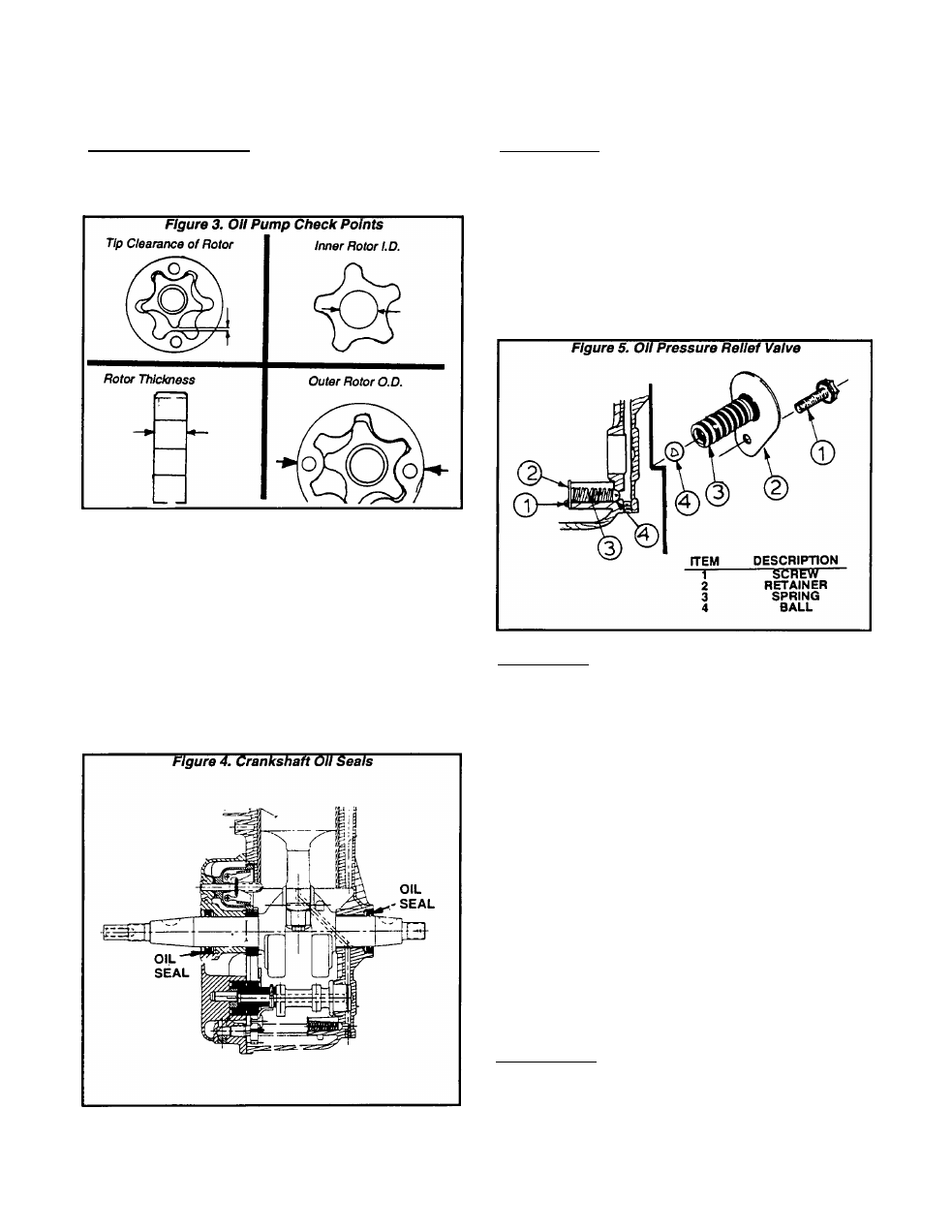

Crankshaft Oil Seals

An oil seal Is provided In the crankcase and in

the oil sump, to prevent leakage past the crankshaft

journals. See Figure 4.

A defective or leaking seal can be replaced. If the

crankshaft has been removed from the engine, old

seals can be removed by tapping out with a screw

driver or punchinq them out from inside. Oil seal

pullers are available commercially, for seal removal

with the crankshaft installed.

Always use a seal protector when Installing the

crankshaft into its crankcase bore and when In

stalling the oil sump over the crankshaft.

Pressure Relief Valve

DESCRIPTION:

A ball type pressure relief valve Is located In a

bore of the crankcase. The ball and spring are

retained in the crankcase bore by a spring retainer.

The Relief Valve serves to limit oil pressure to a

maximum value. The ball will remain against Its

seat as long as oil pressure In the crankcase oil

passage is below approximately 30 psi (29 kg/cm^).

Should oil pressure increase above that value, the

ball will be forced off Its seat to relieve excess

pressure Into the crankcase.

INSPECTION:

Remove the 8mm screw that retains the spring

RETAINER to the crankcase interior. Remove the

RETAINER, SPRING and BALL. Clean all parts In

solvent.

Inspect the BALL and RETAINER for damage,

excessive wear. Replace any damaged or worn

components. Inspect the SPRING and replace If

damaged or worn.

Apply a known test load to the SPRING, sufficient

to compress the spring to a length of 1.03 inch

(26.3mm). The amount of the test load at the stated

spring length should be as follows:

FORCE REQUIRED TO COMPRESS

RELIEF VALVE SPRING TO 1.03 INCH (26.3mm)

0.86-0.95 pounds (0.43-0.39 kg)

If the test load at the stated length is not within

limits, replace the SPRING.

Breather Assembly

DESCRIPTION:

A crankcase breather Is located In the crankcase

assembly.

Page 5.1-2