Testing the battery charge circuit (continued), Testing the ccg circuit board – Generac Power Systems NP-40G User Manual

Page 24

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 1.5- COMPONENTS TESTING

Testing the Battery Charge Circuit

(Continued)

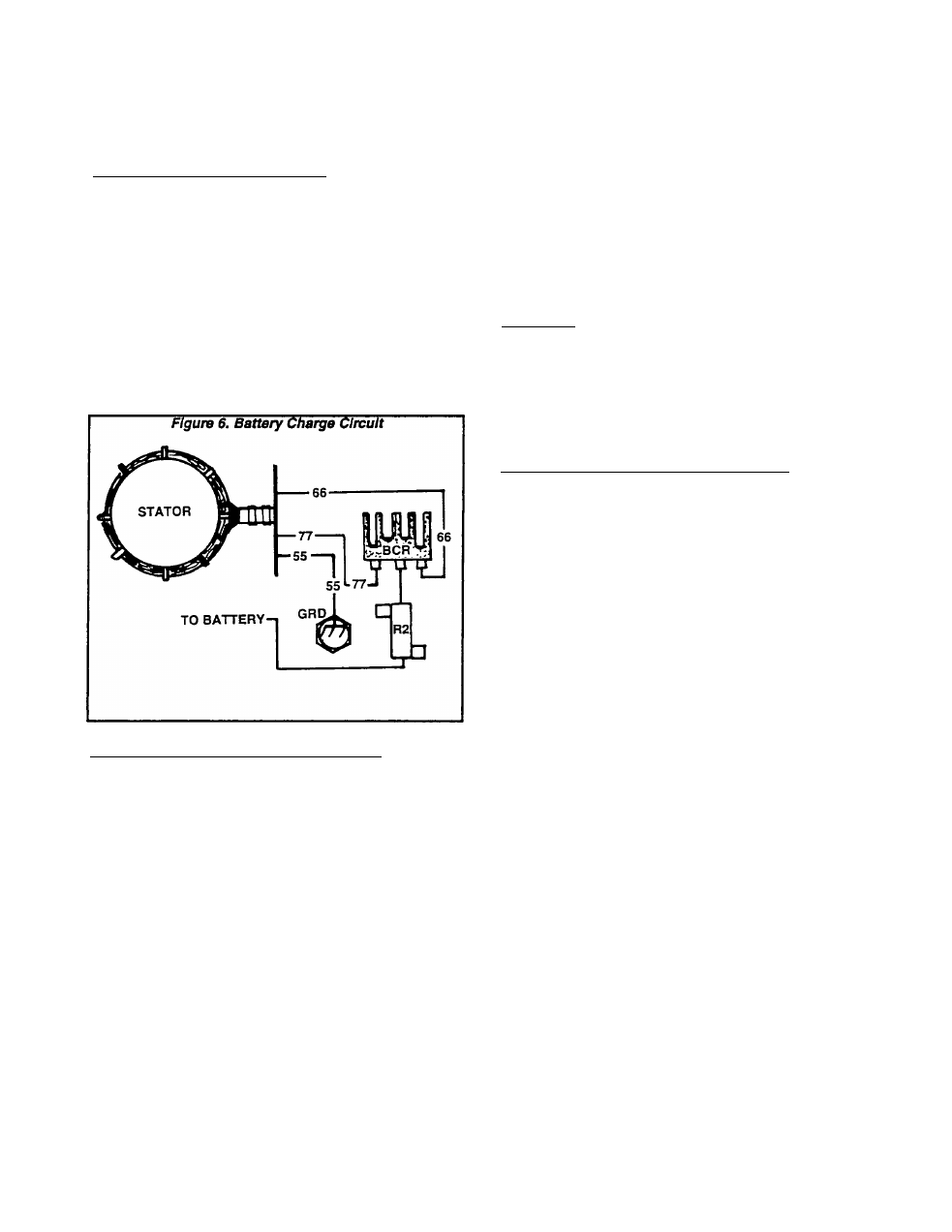

SYMPTOMS OF CIRCUIT FAILURE:

It is difficult to determine if the battery charm

circuit is operating without testing for correct volt

age. If you suspect the battwery charge circuit Is

defective,

the

following

symptoms

will

usually

point to a cause of the problem. See Figure 6.

1. If no AC voltage can be measured across Stator

connections at the Battery Charge Rectifier (BCR),

an open circuit condition probably exists in Wire 66

(Brown), or Wire 77 (Brown).

2. If AC voltage is available to the Wire 66 and 77

terminals at the battery Charge Rectifier, but no

voltage or a low voltage Is measured between the

BCR’s Wire 55 terminal and ground, the Battery

Charge Rectifier (BCR) Is defective.

TESTING THE BATTERY CHARGE CIRCUIT:

Test the Battery Charge winding as follows:

1. Disconnect Wire 77 at the Battery Charge Recti

fier (BCR).

2. Disconnect Stator output Wire 66 at the Battery

Charge Rectifier (BCR).

3. Disconnect Wire 55.

4. Set a VOM to its ”Rx1" scale and zero the meter.

5. Connect the VOM test leads across Wires 77 and

55, then across Wires 66 and 55. Note the resis

tance reading in both cases. Replace Stator As

sembly, If defective.

BATTERY CHARGE WINDING RESISTANCE

ACROSS WIRES 66 TO 55 s 0.037-0.042 Ohm

ACROSS WIRES

77

TO

55

s 0.037-0.042 Ohm

6. Use a VOM to measure AC voltage at the Wires

66 and 77 terminals of the Battery Charge

Rectifier, with the unit running. If no AC voltage is

measured, an open circuit exists in the wire 66 or

77 circuit.

7. With engine running, use a VOM to check for DC

voltage between the Battery Charge Rectifiers

Wire 55 and frame ground. If AC voltage was pre

sent in step 6, but DC voltage is NOT present in

this stem, the Battery Charge Rectifier (BCR) is

d6f6CtiVG.

Testing the CCG Circuit Board

GENERAL:

It is difficult if not impossible to test the CCG

circuit board in the field. Generally, if the other

components in the AC generator system have

tested good, you may assume that any problem is

In the CCG circuit board.

NOTE: Also refer to “CCG Circuit Board" on Pages

Ï.2-4,

1^-5, and 1^-6.

SYMPTOMS OF CIRCUIT BOARD FAILURE:

1. If the engine starts, but the Stepper Motor does

not move, and engine shuts down after several

seconds, the CCG circuit board’s micro-controiler

may not be operating.

2.

A failure of the circuit board’s Stepper Motor

drive can result in the following:

a.

Engine starts, but Stepper Motor does not

move.

The

engine

accelerates

uncontrollably

and shuts down when engine speed exceeds

4500 rpm.

b.

Engine starts, but Stepper Motor does not

move. The following symptoms occur:

(1) Engine appears to operate too slowly.

(2) Engine is not able to handle the load and unit

operates at low AC output voltage.

(3) After several seconds under load, AC output

voltage is turned off (overload condition).

3. If the engine can be started, but shuts down after

several seconds, a timing detection faiiure may

have occured (Timing winding. Wires TIM1, T1M2).

4. if the engine speed and output voltage are erratic

under constant load, but the AC output does not

turn off intermittently, erratic timing detection may

have occured (Timing winding. Wires TIM1, TIM2).

NOTE:

Timing

detection

Involves

the

circuit

board’s ability to detect "zero crosslrws" of the

sine wave (see “Alternating Current", Pages 1.1-1

and 1.1-2). The CCG clrculfboard must detect both

zero VOLTAGE and zero CURRENT crossings If the

system Is to operate properly. This “zero crossing“

detector Is used to synchronize an Internal clock

on the circuit board. The frequency of the Input

waveform la measured by the circuit board and

checked against a "reference“ frequency. The

board then calculates a frequency divisor. By

counting “zero voltage crossings“, an Internal ret-

erence output polarity Is generated. The Genistor

switch with the maximum potential In the direction

of the Internal reference Is gated.

Page 1.5-4