Connecting rod, Assembly and installation, Cylinder service – Generac Power Systems NP-40G User Manual

Page 46

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 2.3- PISTON, RINGS, CONNECTING ROD

SECOND RING END GAP )GN190 & GN220)

DESIGN GAP: 0.006-0.016 Inch (0.15-0.40mm)

WEAR LIMIT: 0.024 Inch (0.60mm) Maximum

OIL RING END GAP (GN190 & GN220)

DESIGN GAP: 0.015-0.055 Inch (0.38-1.40mm)

WEAR LIMIT: 0.062 Inch (1.60mm) Maximum

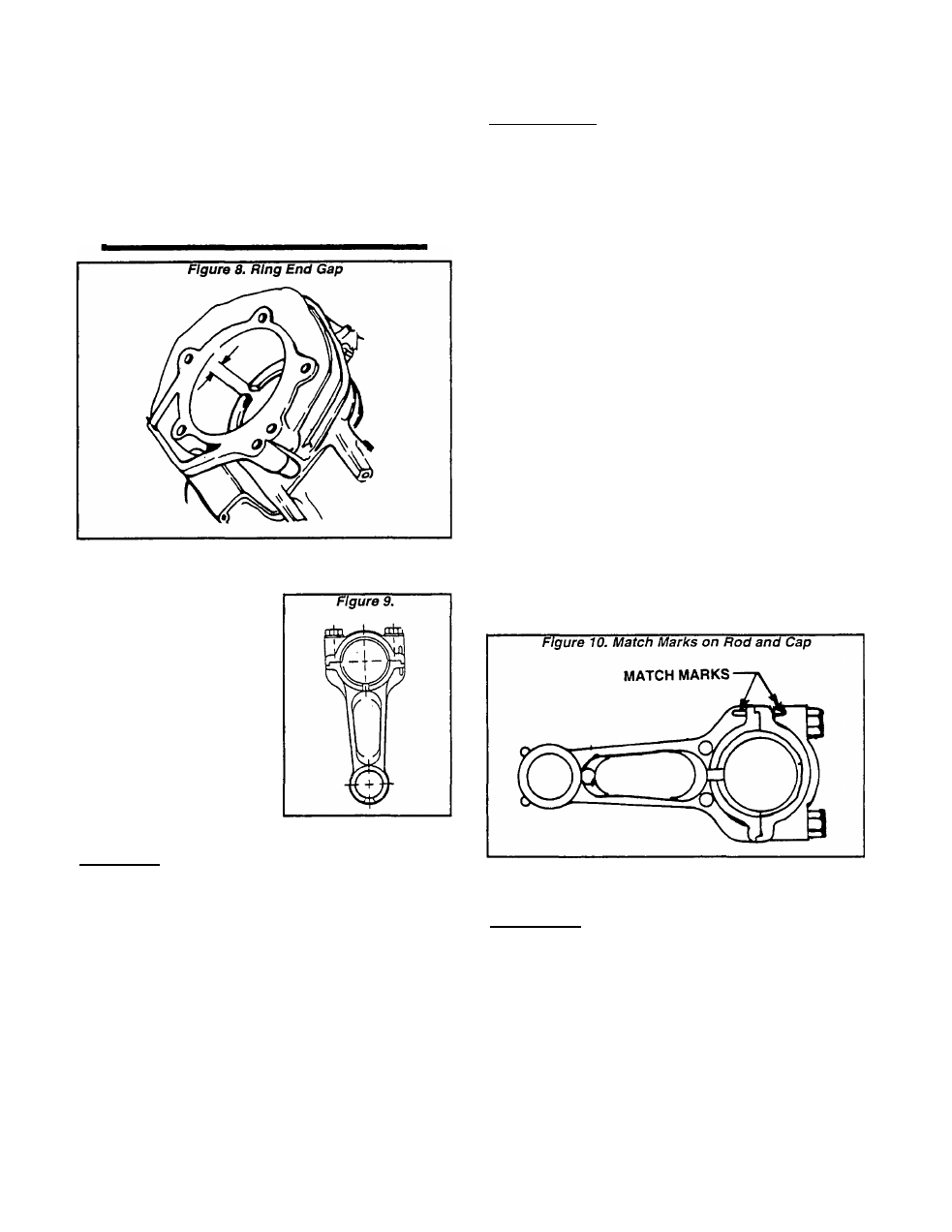

Connecting Rod

Tha connecting rod Is man

ufactured of die cast alumi

num. Alignment marks are

provided on the rod and on the

connecting rod cap. Be sure to

align these marks when as

sembling the rod to the crank

shaft. Connecting rod bolts

are of the "washerless" type.

The connecting rod and the

connecting rod cap are a

matched set and must be re

placed as a matched set

Assembly and Installation

ASSEMBLY:

Use a ring expander when Installing rings Into the

piston ring grooves. Install the OIL RING ASSEMBLY

first. Then, Install the second compression ring with its

Inside chamfer facing up. Finally, install the top com

pression ring.

When assembling the piston, connecting rod and wrist

pin, the assembly marks on the piston must be toward

the flywheel side of the engine.

Coat the wrist pin, wrist pin bore In piston, and wrist

pin bore in the rod with engine oil. Install one snap ring

Into the piston’s wrist pin bore. Then, assemble the

piston to the rod. Slide the wrist pin through one piston

bore, through the rod bore, and through the second

piston bore until It contacts the snap ring. Then, Install

the second snap ring into the piston bore.

INSTALLATION:

Coat the cylinder walls with engine oil, as well as the

crank throw, connecting rod bearing and connecting rod

cap bearing. Then, Install the rod and piston assembly

as follows:

1. Use a ring compressor to compress the rings Into the

piston ring grooves. MAKE SURE ALL RINGS ARE

FULLY COMPRESSED INTO THEIR GROOVES.

2. Guide the connecting rod Into the cylinder, with as

sembly mark on piston toward the flywheel side of en

gine.

3. When the ring compressor contacts top of cylinder,

use a wood hammer handle to gently tap the piston down

into the cylinder.

4. Check that the connecting rod’s large diameter bear

ing is coated with oil, as well as the crank throw and the

connecting rod cap.

5. Guide the large end of the connecting rod onto the

crankshaft Install the connecting rod cap. The match

mark on the cap must be aligned with an Identical mark

on the rod (Figure 10).

6. Install the corinecting rod cap bolts and tighten to the

proper torque.

TIGHTENING TORQUE

CONNECTING ROD CAP BOLTS (GN190 & GN220)

10 foot-pounds (1.36 N-m)

NOTE: The connecting rod can be Installed In either

direction. That Is, the cap marks on the rod and cap

may face toward the Installer or away from the

Installer. The only requirement Is that the assembly

mark on top of piston be toward the flywheel side

of engine.

Cylinder Service

INSPECTION:

Check the cylinder for dirty, broken or cracked fins.

Also look for worn or scored bearings, or a scored

cylinder wall. Check the cylinder head mounting surface

for warpage. If the head is warped, it must be replaced.

If the cylinder bore Is worn (as evidenced by excessive

ring end gap), the cylinder should be replaced or rebored

to 0.010 or 0.020 (0.25 or 0.50mm) oversize.

After reboring the cylinder to a specific oversize, In

stall an Identically oversize piston along with identically

oversized rings.

Page 2.3-3