Engine speed, Throttle linkage adjustment – Generac Power Systems NP-40G User Manual

Page 61

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 3.4- CARBURETOR

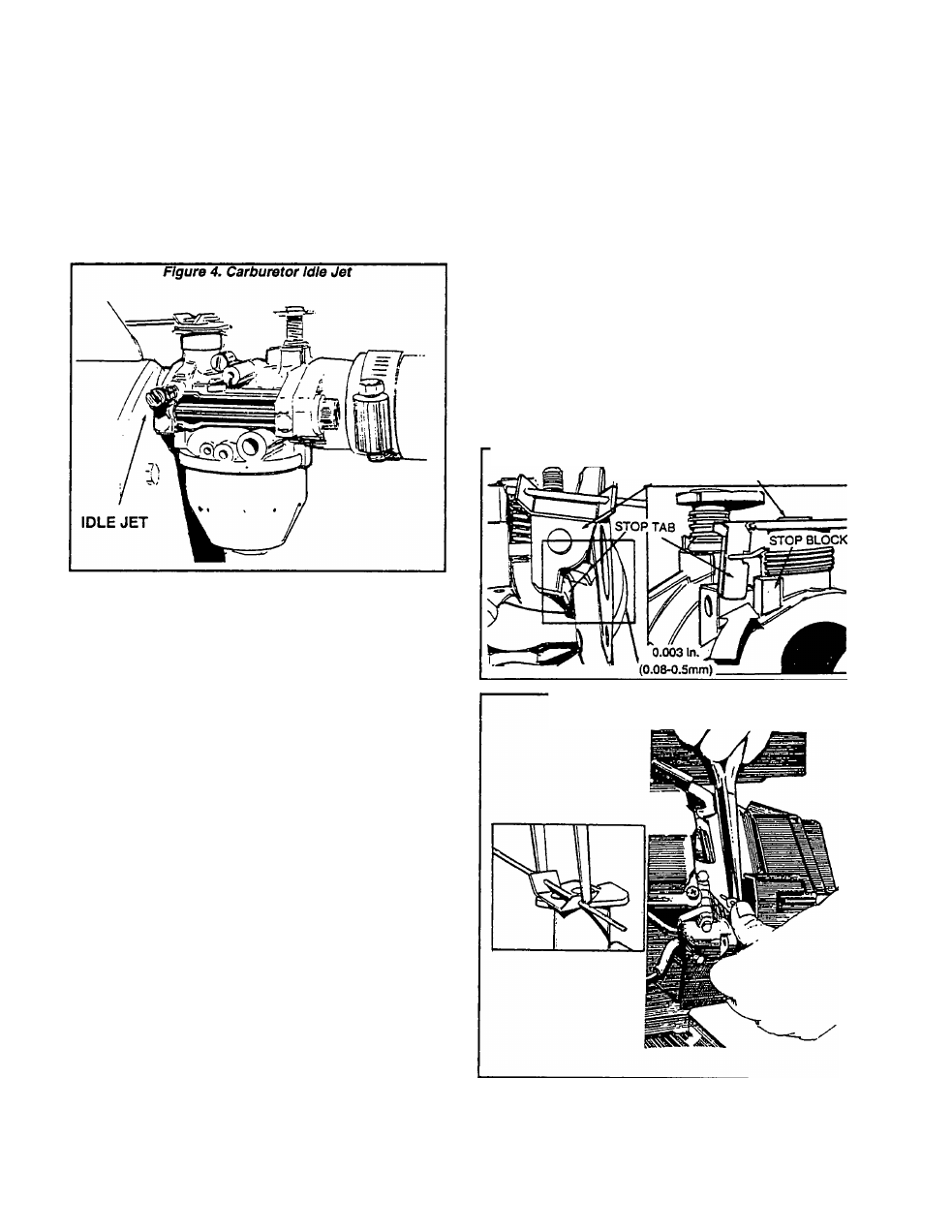

1. with enqine running at no-load, turn the IDLE JET

clockwise (leaner) until engine speed starts to decrease

or fluctuate.

2. Turn the IDLE JET counterclockwise (richer) until

engine speed starts to decrease or fluctuate or until

black smoke comes from exhaust.

3. Very SLOWLY turn the IDLE JET clockwise (leaner)

until engine speed just stabilizes or until black smoke

just stops coming from exhaust 00 NOT turn the JET

excessively lean.

Engine Speed

Engine speed is controlled by the CCG circuit

board. That circuit board signals a stepper motor

which moves the throttle linkage. Engine speed will

vary in response to changes In generator AC output

voltage.

The circuit board monitors the demand for power

and adjusts the engine speed accordingly. This

permits the engine to deliver only the power

needed.

NOTE: Do NOT attempt to accelerate the enalne

manually by grasping the throttle or throttle link

age. This win cause the system to enter a fault

condition and terminate generator AC output.

Throttle Linkage Adjustment

If necessary, the length of the linkage between

the stepper motor and the carburetor throttle lever

arm can be adjusted. This adjustment helps to

establish the proper travel relationship of the link

age. If the adjustment is not correct, the CCG board

will not be able to control the full range of engine

speed. The following conditions might occur:

G

If the throttle linkage Is set too short, the system will

not be able to provide wide open throttle or full

power conditions.

G

If the linkage Is set too long, the system will not be

able to provide closed throttle or no power condi

tions.

Use the following procedure to ensure the link

age rod is properly adjusted:

1. Start the engine and immediately shut it down. As the

engine coasts to a stop, observe from above the engine

as the carburetor throttle lever rotates counterclockwise.

2. There should be a gap of about 0.003 inch (0.08-0.5mm)

between the stop tab on the throttle lever arm and the

stop block on the carburetor casting. See Figure 5.

CAUTION!

The next step Involves bending a spring clip. Do

NOT overbend the clip or it may lose its clamping

force.

3. Use pliers to lightly compress the spring clip on the

carburetor lever arm (Figure 6). This permits the linkage

rod to slide freely through the clip. With the clip com

pressed, rotate the throttle lever in the appropriate direc

tion until there is a 0.003 Inch (0.08-0.5mm) gap.

4. Release the spring clip to lock In the adjustment

Figure 5. Set Between Stop Tab and Stop Block

THROTTLE LEVER ARM

Figure 6. Adjusting Throttle Linkage

Page 3.4-3