Introduction to oil system, Oil flow, Oil pickup screen – Generac Power Systems NP-40G User Manual

Page 77: Oil pump

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 5.1- ENGINE OIL SYSTEM

Introduction to Oil System

The engine oil system serves to (a) reduce fric

tion between parts, (b) cool the engine, and (c)

establish a slightly negative pressure In the crank

case to prevent oil leakage. Major components that

will be discussed in this section Include the follow

ing:

□ Oil PIckupScreen.

□ Oil Pump.

□ Crankshaft OH Seals.

□ Pressure Relief Valve.

□ Breather Assembly.

□ Oil Sump.

n Oil Filter Support Assembly.

Oil Flow

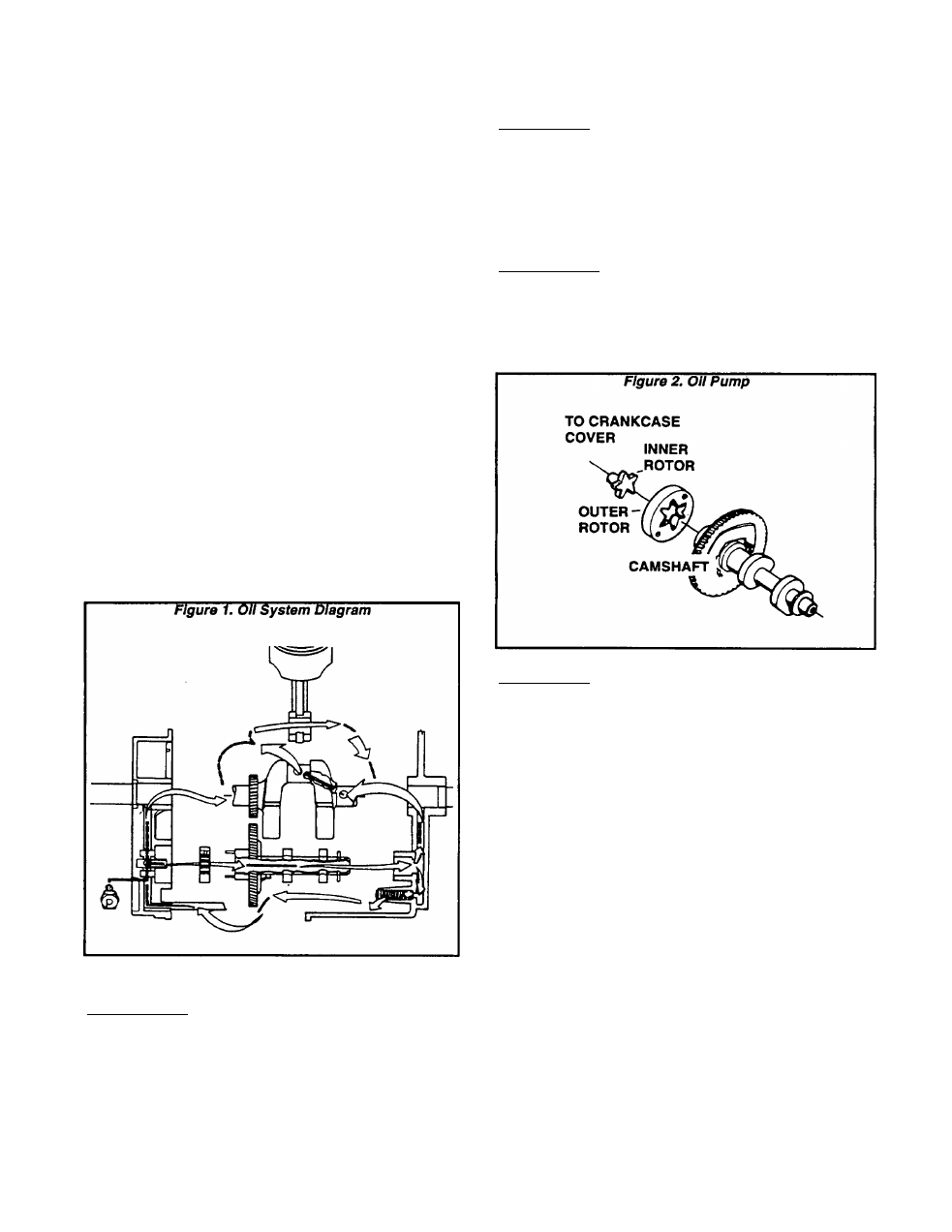

See Figure 1. The oil pump draws oil from the oil

sump through an oil pickup screen and delivers It

to the areas requiring lubrication as follows:

1. Through a cored channel In the oil sump to the crank

case Journal at one end of the crankshaft

2. Through the hollow camshaft to the camshaft bearing.

3. Through a cored passage In the crankcase to the

crankshaft Journal.

4. Through the crankshaft to the crankpin and connect

ing rod bearing.

Oil Pickup Screen

DESCRIPTION:

The oil pickup screen consists of a cylindrical

screen which Is open at one end only. The screen’s

open end fits over a tubular protrusion In the oil

sump. Just behind the oil filter support. Also see

"

Oil Filter Support Assembly".

INSPECTION:

To gain access to the screen, remove the oil filter

support and its gasket. Pull the screen off Its

tubular protrusion. Clean the screen In solvent,

then Inspect for damage. Replace the screen If

necessary.

Oil Pump

DESCRIPTION:

The oil pump Is of the trochoid type. Its Inner

rotor rotates on a shaft provided In the camshaft

bore of the oil sump. The outer rotor Is Installed

over two drive pins on the end of the camshaft and

Is driven by camshaft rotation.

INSPECTION:

See Figure 3. Inspect the Inner and outer rotors

of the pump for damage and wear. Use a feeler

gauge to check tip clearance of the rotor (measured

on the shaft in the oil sump). Check the bore Inner

diameter and the thickness of the Inner rotor. If

wear limits are exceeded, replace the appropriate

part(s).

PUMP TIP CLEARANCE

(MEASURED ON SHAFT IN OIL SUMP)

DESIGN CLEARANCE: 0.0000-0.0010 Inch

(0.000-0.025mm)

WEAR LIMIT: 0.004 Inch (0.105mm) Maximum

INNER PUMP ROTOR BORE

DESIGN BORE: 0.354-0.355 Inch (9.000-9.019mm)

WEAR LIMIT: 0.357 Inch (9.034mm) Maximum

INNER ROTOR THICKNESS

DESIGN THICKNESS: 0.312-0.315 Inch (7.95-8.00mm)

WEAR LIMIT: 0.311 Inch (7.90mm) Minimum

Replace any part that is damaged or worn exces

sively. The shaft on which the inner rotor rotates

is NOT repiaceabie (oil sump must be replaced).

Page 5.1-1