Valve service (continued), Valve components installation – Generac Power Systems NP-40G User Manual

Page 40

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

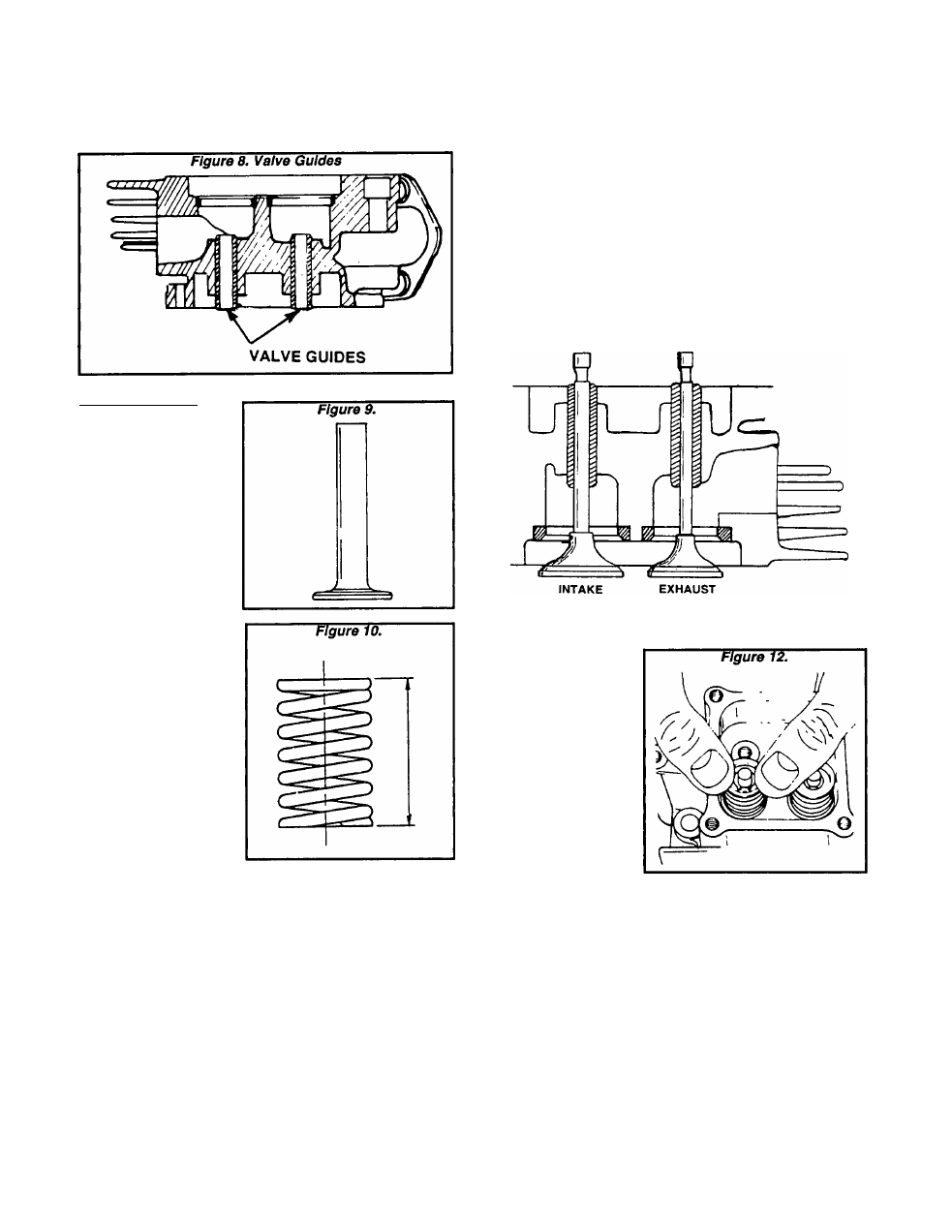

Section 2.2- VALVE TRAIN

Valve Service (Continued)

VALVE TAPPETS!

Valve tappets can be

removed during re

moval of the engine

camshaft. Intake and

exhaust valve tappets

are Identical. However,

once a wear pattern

has been established

the two tappets should

not be Interchanged.

VALVE SPRINGS:

Inspect the valve

springs. Measure the

spring free length.

Also, cneck the amount

of force required to

compress the spring to

a length of 1.39 Inch

(35.2 mm). Replace any

damaged or defective

spring.

VALVE SPRING FREE LENGTH

GN190:1.910 Inch (48.48mm)

GN220: 2.074 Inch (52.69mm)

FORCE REQUIRED TO COMPRESS SPRING

TO 1.39 INCH (35.2MM)

GN190:14.8-16.2 lbs (6.7-7.4kg)

GN220:19.8-21.8 lbs (9.0-9.9kg)

Valve Components Installation

After the valve train parts have been Inspected and (If

necessary) serviced. Install them as follows:

1. Lubricate the valve stems and the valve guides with

engine oil.

2. Install the Intake and exhaust valves through their

respective valve guides in the cylinder head.

a. The exhaust valve has the smaller head with a

diameter of 1.053 Inches (26.75mm).

b. The Intake valve has the larger head, having a

diameter of 1.171 Inches (29.75mm).

c. Valve seat sizes In the cylinder head will match their

respective head sizes.

NOTE: The exhaust valve stem Is also smaller than

that of the Intake valve.

Figure 11. Installation of Intake and Exhaust Valves

BE SURE TO LUBRICATE VALVE

GUIDES A STEMSI

3. Install the valve

spring washers, valve

springs and valve

spring retainers over

the valve guides.

a. Hold the valve

with your fingers

and

use

your

thumbs to com

press the spring.

b. When the spring

Is compressed suf

ficiently, slide the

spring

retainer

small opening over

the valve stem.

c. With the smaller

retainer opening

around the valve

stem, release the spring.

4. After both valves have been retained in the cylinder

head, position a new head gasket and Install the cylinder

head.

NOTE: The head gasket Is coated with a special

substance for better sealing. The gasket must be

free of nicks, scratches and other defects for better

sealing.

5. Install cylinder head bolts. Tighten the head bolts In

the sequence shown to the recommended tightness.

Page 2.2-3