Valve components installation (continued), Adjusting valve clearance – Generac Power Systems NP-40G User Manual

Page 41

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 2.2- VALVE TRAIN

Valve Components Installation

(Continued)

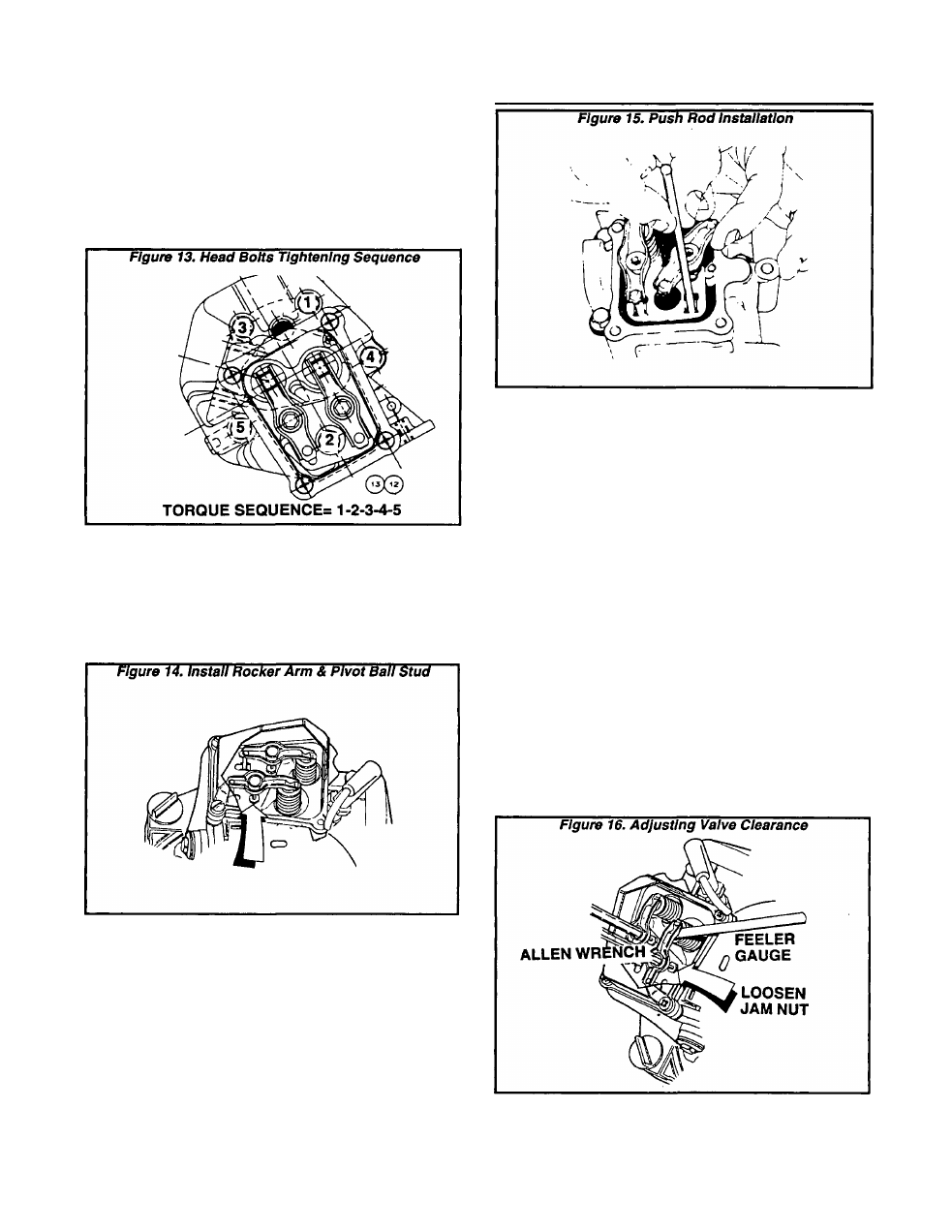

TIGHTENING TORQUE

CYLINDER HEAD

GN190: 25 foot-pounds

GN220: 29 foot-pounds

6. Place the push rod guide plate Into position on the

head. Then, Install the rocker arm and the pivot ball

stud. The rocker arm Jam nut must be on far enough to

hold the guide plate In position.

NOTE: Do NOT adjust valve clearance at this time.

This will be done later.

7. Install the push rod with either end against the tappet

a. Place the push rod between the guide plate tabs.

b. Place the rocker arm socket onto end of push rod.

c. Alignment Is correct when push rod ball rests In the

rocker arm socket.

NOTE: The pivot ball stud will be tightened when

the valve clearance Is adjusted. After valve clear

ance has been adjusted, the rocker arm cover will

be Installed.

Adjusting Valve Clearance

When adjusting valve clearance, the enolne should be

at room tenmerature and the piston shouldbe at top dead

center (TDC) of Its compression stroke (both valves

closed).

VALVE CLEARANCE

GN190 ENGINE

INTAKE VALVE: 0.001-0.003 Inch (0.03-0.07mm)

EXHAUST VALVE: 0.001-0.003 Inch (0.03-0.07mm)

VALVE CLEARANCE

GN220 ENGINE

INTAKE VALVE: 0.001-0.0022 Inch (0.03-0.056mm)

EXHAUST VALVE: 0.0018-0.003 Inch (0.046-0.07mm)

Adjust the valve clearance as follows:

1. Rotate the crankshaft until the piston Is at top dead

center (TDC) of Its compression stroke. Both valves

should be closed.

2. Loosen the rocker arm Jam nut

3. Use an alien wrench to turn the pivot ball stud while

checking the clearance between the rocker arm and the

valve stem with a feeler gauge.

Page 2.2-4