Section 2.3- piston, rings, connecting rod, Oversize piston & rings, Prior to removai – Generac Power Systems NP-40G User Manual

Page 44: Removai, Piston

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

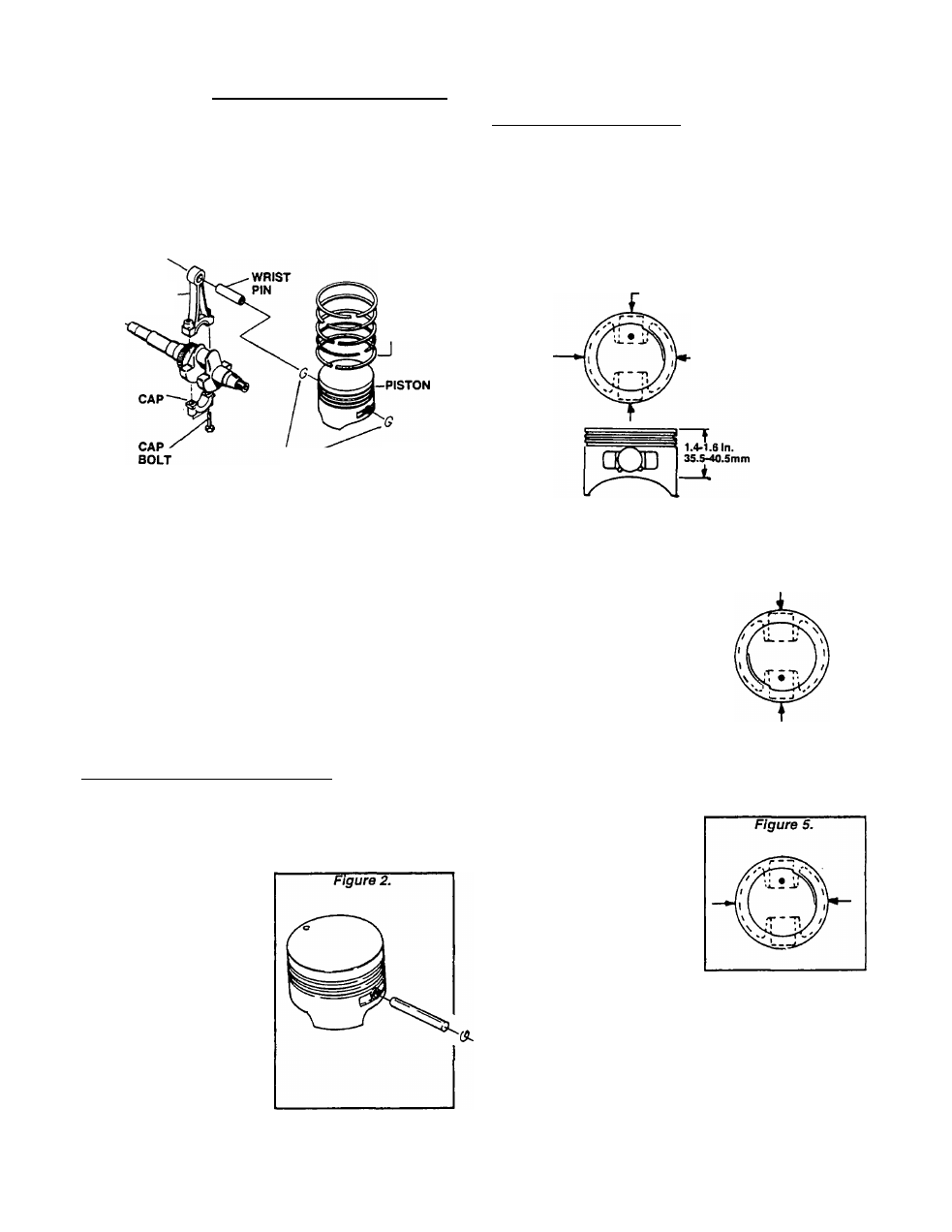

_________ Section 2.3- PISTON, RINGS, CONNECTING ROD

Oversize Piston & Rings

Worn or scored cylinders may be rebored to 0.010

(OJZSmm) or 0.020 (0.50mm) oversize. Pistons and pis

ton rings of matching oversize are

available

to fit the

rebored cylinder.

Figure 1. Piston, Rings and Connecting Rod

CONNECTING -

ROD

-RINGS

SNAP"

RING

Prior to Removai

Before removing pistons, rings and connecting rod,

clean all carbon from the cylinder bore. Carbon buildup

In the cylinder bore can cause ring breakage during

piston removal.

Removai

Remove the connecting rod CAP BOLTS and the con

necting rod CAP. Then, push the piston and connecting

rod out through top of cylinder.

Piston

REMOVE FROM CONNECTING ROD;

NOTE: An oil hole In the wrist pin area of the piston

helps distribute oil to assist In cooling. The oil hole

also provides an assist In removing the wrist pin

snap ring.

To remove the piston from

the connecting rod, proceed

as follows:

1. Move the snap ring around

until its protruding end is

aligned with the notched out

oil hole. Use needle nose pli

ers to turn the snap ring and

puil it toward you.

2. With one snap ring re

moved, slide the wrist pin

out of the piston boss. This

will separate the piston from

the connecting rod.

CHECK FOR PISTON WEAR:

The piston is slightly elliptical. It’s smaller diam

eter is in line with the wrist pin boss. It’s larger

diameter is 90° from the wrist pin boss.

NOTE: An assembly mark Is provided on the piston.

This mark should face the flywheel end of the

crankshaft (3:00 position) during reassembly.

Figure 3. Elliptical Shape of Piston

2.747-2.748 In.

69.789-69.809mm

2.753-2.754 In.

69.939-89-959tnm

To check the piston for wear, proceed as follows:

Figure 4.

1. Minor Diameter:- At a posi

tion directly in line with the

wrist pin hole, measure from

top of piston down to a dis

tance of 1.4-1.6 Inches (35.5-

40.5mm). This is the "minor"

diameter. Measure at this point

to check for wear.

PISTON MINOR DIAMETER (GN190 & GN220)

DESIGN DIAMETER: 2.747-2.748 inch (69.789-

69.809mm)

WEAR LIMIT: 2.745 Inch (69.739mm) Minimum

2. Major Diameter:- At a point

90* from the wrist pin bore,

measure down 1.4-1.6 inches

(35.5-40.5mm). This Is the

"major" diameter. Measure at

this point to check for piston

wear. Replace the piston if wear

limits are exceeded.

3. Check wrist Pin for Looseness:- A rough check for

wear in the wrist pin, wrist pin bore in the piston, or wrist

pin bore In the connecting rod is to check for looseness

or play with the piston assembled to the rod. Looseness

or play Indicates a worn wrist pin, or a worn bore in the

piston or connecting rod.

NOTE: Always apply engine oil to wrist pin and Its

bores during Installation. Wrist pin fit Is very close.

Page 2.3-1