Carburetor disassembly (continued), Cleaning and inspection, Adjustment – Generac Power Systems NP-40G User Manual

Page 60: Carburetor disassembly (contin ued)

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

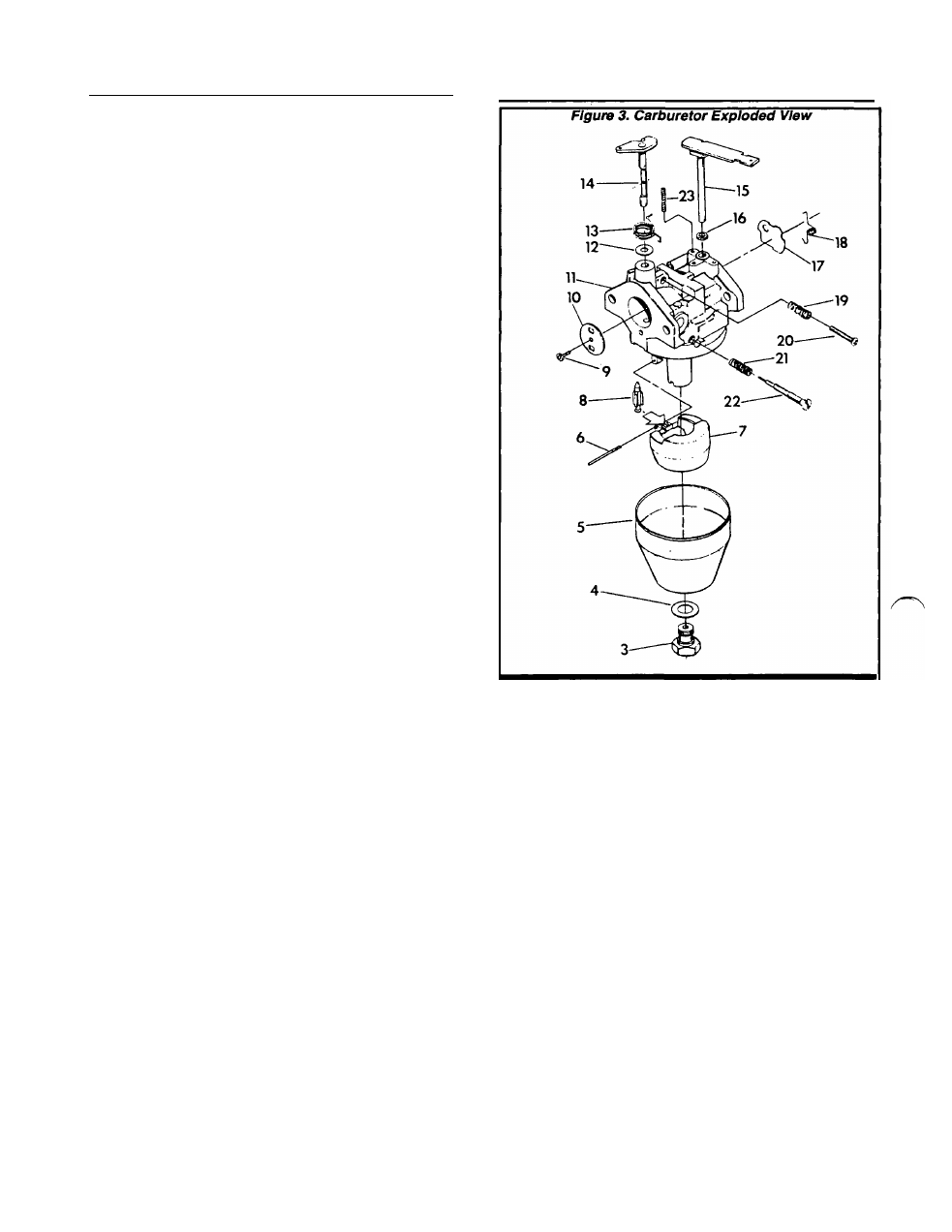

Carburetor Disassembly (Contin

ued)

3. Remove the IDLE MIXTURE SCREW (Item 22) with

SPRING (Item 21).

4. Remove thie IDLE SPEED SCREW (Item 20) with

SPRING (Item 19).

5. Rotate the THROTTLE VALVE (Item 10) to Its closed

?

osltlon and remove the SCREW (Item 9). Remove the

HROTTLE VALVE.

6. Remove the THROTTLE SHAFT (Item 14), along with

the THROTTLE SHAFT SPRING (Item 13) and the THROT

TLE SHAFT SEAL (Item 12).

7. Remove the CHOKE VALVE SPRING RETAINER (Item

18). Remove the CHOKE VALVE (Item 17). Remove the

CHOKE SHAFT (Item 15) and the SHAFT SEAL (Item 16).

Section 3.4- CARBURETOR

Cleaning and Inspection

1. Separate all non-metallic parts.

2. Clean metallic parts In a solvent or a commercial

cleaner. Soak the parts no longer than about 30 minutes.

3. Inspect throttle lever and plate. Replace If worn or

damaged.

4. Inspect the Idle mixture screw. Check the point as well

as Its seating surface for damage. Replace the screw, If

damaged.

5. The float bowl must be free of dirt and corrosion. Use

a new float bowl gasket when assembling the bowl.

6. Check the float for damage. Replace, if damaged. The

float setting is fixed and non-adjustable.

7. The carburetor body contains a main Jet tube that Is

pressed In to a fixed depth. Do NOT attempt to remove

this tube. Tube movement will adversely affect carbu

retor metering characteristics.

8. After soaking In solvent, blow out all passages with

compressed air.

Adjustment

The carburetor is equipped only with an idle jet

adjustment. This jet controls the fuel-air mixture

from light to no-load conditions. The carburetor’s

high speed jet is FIXED and NON-ADJUSTABLE.

If the engine is operated at a significantly differ

ent altitude than the factory (900 feet above sea

levei). It may become necessaiy to readjust the idle

jet. The fuel-air mixture must be set LEANER for

high altitudes. If the unit is moved back to a lower

altitude, return the jet to a richer setting.

CAUTIONI

Do NOT adjust the fuel-air mixture excessively

lean. An excessively lean mixture can result in

engine damage.

See Figure 4, next page. Turn the IDLE JET In

ward (clockwise) until it just contacts its seat. DO

NOT FORCE. Then, turn the IDLE JET outward

(counterclockwise) 1-1/8 turns. This initial adjust

ment should allow the engine to be started and

warmed up.

3. Bowl Nut

4. Fiber Washer

5. Float Bowl

6. Float Pin

7. Float

8. Infet Valve

9. Screw

10. Throttle Valve

11. Body

12. Throttle Shaft Seal

13. Throttle Shaft Spring

14. Throttle Shaft

15. Choke Shaft

16. Choke Shaft Seal

17. Choke Valve

18. Choke Valve Spring Retainer

19. Idle Speed Screw Spring

20. Idle Speed Screw

21. Idle Mixture Screw Spring

22. Idle Mixture Screw.

NOTE: Item 20 used

only on Serial No.’s

1354194-1354198 and

1361541-1361600. On

other units. Idle Speed

Screw has been rem

oved.

After the initial adjustment, start the engine and

let it warm up for about five (5) minutes. If the

engine runs rough or if exhaust smoke is black,

proceed as follows:

Page 3.4-2

Revised- 02/07/95