Test 22-test automatic choke, Test 23- check carburetion, Test 24- check engine – Generac Power Systems NP-40G User Manual

Page 113

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

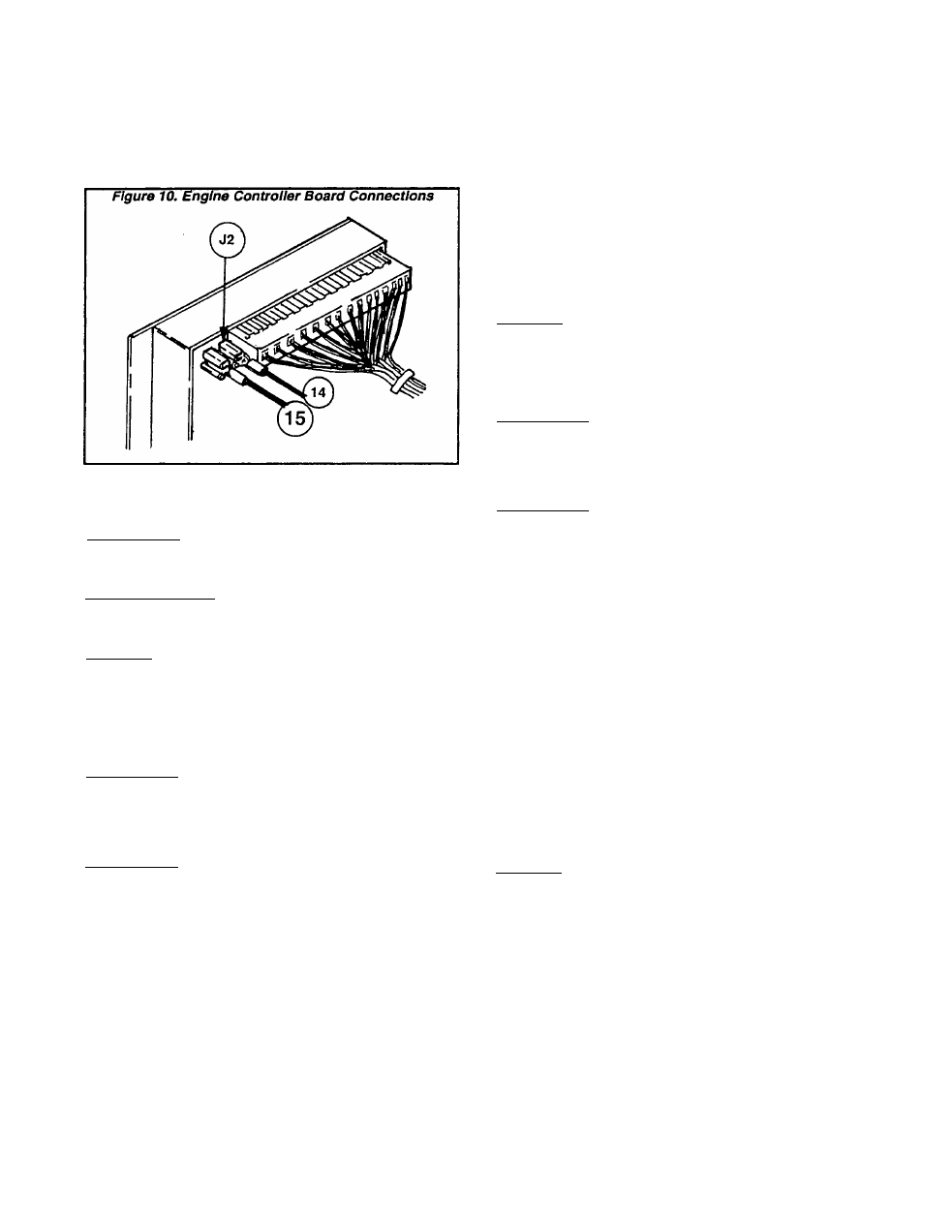

Section 7.2- ENGINE DC CONTROL SYSTEM

3.

If there is no DC output from the circuit board

to Wire 14, replace the Engine Controller circuit

board.

Test 22-Test Automatic Choke

DtSCUSSION:

Refer to Section 3.5, "AUTOMATIC CHOKE“.

TEST PROCEDURE:

See Section 3.5.

RESULTS:

1. Adjust or repair choke system as necessary.

2. If choke is good, go to Test 23.

Test 23- Check Carburetion

DISCUSSION:

If the engine won’t start or if it starts hard and

runs rough, one possible cause of the problem is

carburetion.

PROCEDURE:

Before making a carburetion check, make sure

the fuel tank has an ample supply of clean fresh

gasoline (gasoline fuel systems) or gaseous fuel.

The Installer may have Installed a gas or gasoline

shutoff valve in the fuel supply system. Make sure

all shutoff valves are open.

Adjust the carburetor as outlined on Page 3.4-2.

Make sure the automatic choke is working properly

and that the choke closes completely.

If the engine will not start, remove the spark plug

and Inspect it. If the plug is WET, look for the

following:

□ Overchoking.

□ Water in fuel.

□ Excessively rich fuel mixture.

□ Intake valve stuck open.

If the spark plug is DRY, look for the following:

□ Carburetor gasket(s) leaking.

□ Fuel line plugged or shutoff valve not opening.

□ Intake valve stuck closed.

□ Inoperative fuel pump.

□ Clogged fuel filter.

RESULTS:

Adjust or repair carburetor or fuel system as

necessary.

Test 24- Check Engine

DISCUSSION:

An engine that will not start or one that starts

hard and runs rough may be caused by a failure In

the engine’s mechanical system.

PROCEDURE:

The first step In checking for an engine problem

Is to perform a compression check. To check en

gine compression, proceed as follows:

1. Remove the spark plug.

2. Insert an automotive type compression gauge

into the spark plug hole.

3. Crank the engine until there Is no further In

crease in pressure. The highest reading obtained

Is the engine’s compression pressure.

ENGINE COMPRESSION PRESSURE

NOMINAL PRESSURE:- 60 psi

MINIMUM ALLOWABLE:- 55 psi

NOTE: Full compression pressure cannot be ob

tained at cranking speeds, due to the action of a

compression release mechanism.

RESULTS:

If compression is poor, look for one or more of

the following possible causes:

1. Loose cylinder head bolts.

2. Failed cylinder head gasket.

3. Burned valves or valve seals.

4. Insufficient valve clearance.

5. Warped cylinder head.

6. Warped valve stem.

7. Worn or broken piston ring(s).

8. Worn or damaged cylinder bore.

9. Broken connecting rod.

Page 7.2-11