Rotor hub, Stator retaining ring, Stator assembly – Generac Power Systems NP-40G User Manual

Page 12: Stator adapter, Lower fan & flywheel, Engine, Stepper motor

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 1.2- MAJOR GENERATOR COMPONENTS

Rotor Hub

See Figure 2. The Rotor Hub Is balanced with the

Rotor and must be replaced with the Rotor as an

assembly. Part of the engine ignition system is

pressed onto the Hub and can be replaced only as

part of the Rotor and Hub assembly.

Stator Retaining Ring

The Stator Retaining Ring is made of dIe-cast

aluminum.

Four

hex

head

capscrews

with

lockwashers pass through holes in the Retaining

Ring, to retain the Stator Assembly to the Stator

Adapter (Item 7, Figure 1).

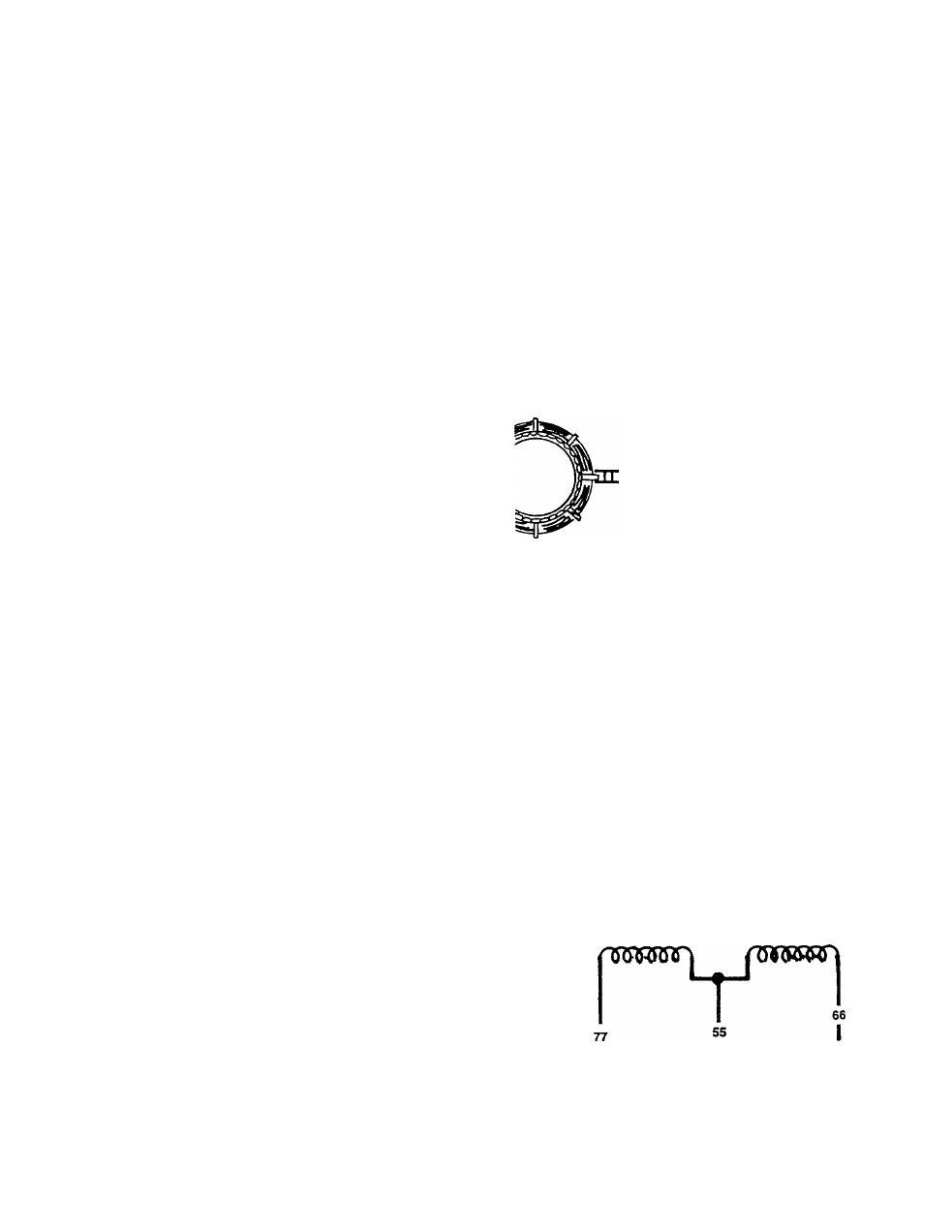

Stator Assembly

The 2-phase Stator is made up of eight (8) wind

ings, with leads brought out as shown in figure 3.

Figure 4 is a schematic representation of each sta

tor winding. Note that there are four (4) power

phase windings (Leads AC2, AC1, SI2, SI1 and 11);

a timing winding (Leads TIM1 and TIM2); a power

supply winding (Leads PS1, PS2); and a dual bat

tery charge winding (Leads 55, 66, 77).

The Stator produces a frequency of 336 to 540

Hertz, which corresponds to engine speeds

between 2520 and 4050 rpm. This means the gen

erated frequency is between six and nine times

the desired frequency of about 60 Hertz.

Stator Adapter

The Adapter Is retained to the engine by means

of four hex head capscrews. The Stator Is retained

to the Stator Adapter and Is “sandwiched'' between

the Adapter and the Stator Retaining Ring.

Lower Fan & Flywheel

The Lower Fan and Flywheel are retained to the

engine PTO shaft by means of a conical washer and

an Ml 6-1.50 hex nut. When assembling, tighten the

flywheel nut to 75 foot-pounds.

Engine

The engine is a single cyclinder, overhead valve

type manufactured by Generac Corporation. De

pending on the specific generator Model Number,

either a GN-190 or a GN-220 engine is used on

NP-30 and NP-40 RV generators.

Stepper Motor

The Stepper Motor (Figure 5, next page) consists

of a stepper motor along with a gear and cam

arrangement

which

allows

motor

movement

to

change the engine carburetor throttle setting. The

Motor Is controlled by output signals from the Com

puter Control Circuit Board, which calculates the

number of steps the stepper needs to take and

generates the required signals to the Motor. The

circuit board signals the Motor to actuate in re

sponse to changes In AC output voltage. Thus, In

response to decreasing AC output voltages, the

Motor will increase the throttle setting and engine

speed will Increase. Conversely, Increasing AC

output voltages will cause the Motor to decrease

throttle setting and engine speed will decrease.

Figure 3. Stator Pictorial View

-55 (BLACK)--------»<§)

-66 (BROWN)-

—77 (BROWN)

T1M1 (ORANGE)

PS2 (YELLOW)

—TM2 (GRAY)

H T1M1 (

-PS1 (BROWN)-

■11 (BLUE) ---------

-AC2 (YELLOW)

-AC1 (GRAY)—

-SL1 (ORANGE)—

----- SL2 (BROWN)-------------

Figure 4. Schematic- Stator Windings

POWER

PHASE 1

AC1

a

C2

AC2

b

POWER

PHASE 2

I

!

I

I

(7»CT«r|

II

è

SL2

è

POWER I

TIMING

SUPPLY I

I

PS1

PS2

C

«r

®

®

BATTERY

CHARGE

Page 1.2-2