Genistor, Testing the battery charge circuit – Generac Power Systems NP-40G User Manual

Page 23

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 1.5- COMPONENTS TESTING

4. Connect one VOM test lead to Stator lead AC1,

the other test lead to Stator lead 77. The VOM

should read "Infinity“.

5. Connect one VOM test lead to Stator lead AC1,

the other test lead to Stator lead TIM1. The meter

should read “Infinity”.

6. Connect one test lead to Stator lead PS1, the

other to Stator lead TIM1. “Infinity" should be

Indicated.

7. Connect one test lead to Stator lead PS1, the

other to Stator lead 77. The VOM should read

"Infinity".

8. Connect one VOM test lead to Stator lead TIMI,

the other test lead to Stator lead 77. “Infinity"

should be Indicated.

Genistor

GENERAL:

The “Genistor" or "Triac Module" is the FRE

QUENCY CONVERTER for the generator. For addi

tional Information on the Genistor, refer to

"The

Genistor"

on Pages 1.2-3 and 1.2-4.

SYMPTOMS OF GENISTOR FAILURE:

If the engine shuts down but speed did not ex

ceed 4500 rpm, the following problems may exist:

1. Loss of the "Gate" connection (G1 through G4)

between the CCG circuit board and the Genistor.

2. Although the correct “Gate" signal Is received

from the CCG board, one or more switches are not

gating.

3. The Genistor is not gating properly, I.e., one or

more switches are permanently turned on.

4. Open circuit or loss of connection(s) between

Stator and Genistor (Leads AC1,

a

C2, SLI, SL2,

22).

5.

Open circuit or loss of connection between

Genistor and CCG circuit board (Leads AC1, AC2,

SL1,SL2).

TESTING THE GENISTOR:

Disconnect ail wires from the Genistor before

attempting to test it.

CAUTIONI

DO NOT attempt to test the Genistor until ALL

leads

have

been

disconnected.

The

genistor

MUST be completely disconnected from the cir

cuit If testing is accomplished with any leads

connected, alftest results are Invalid.

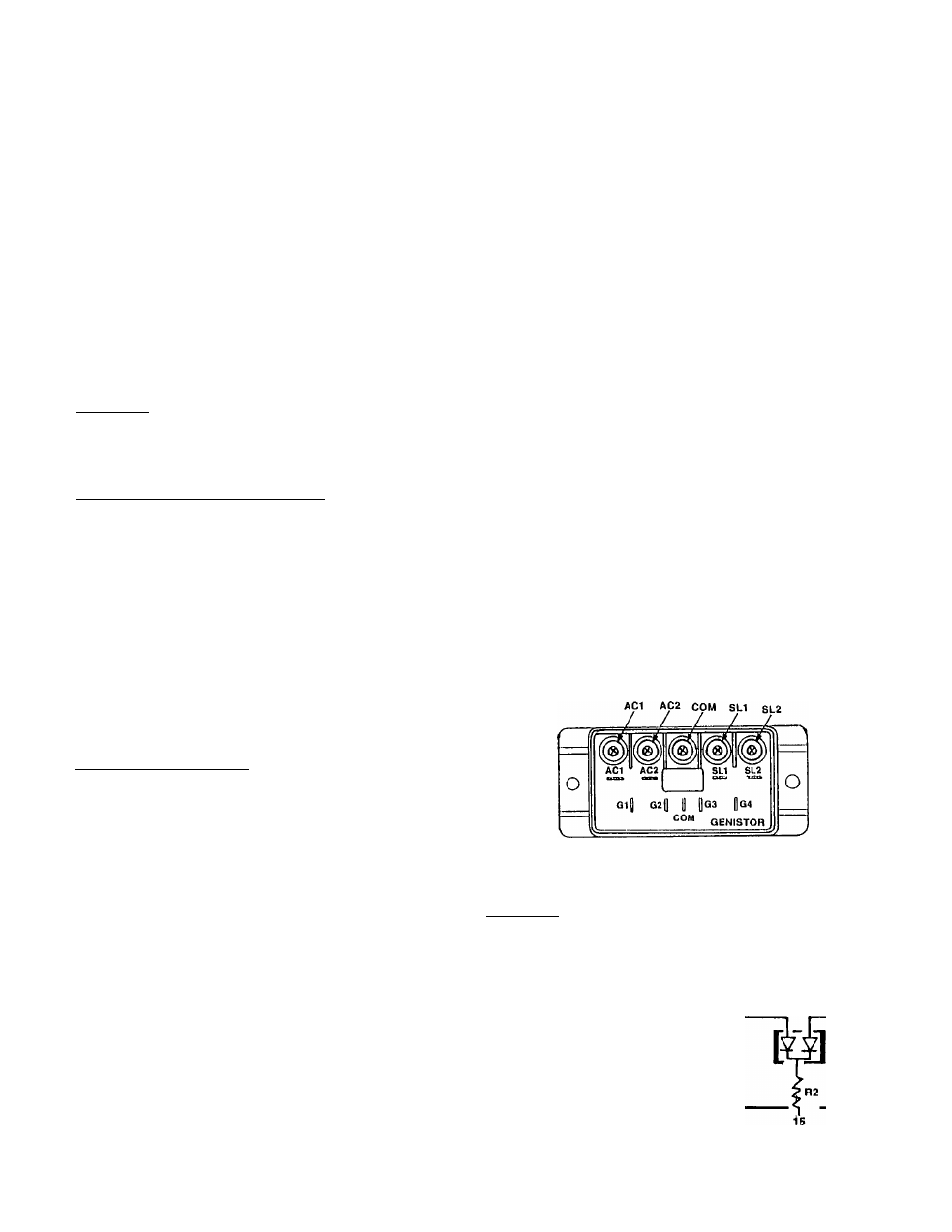

See Figure 4. To test the Genistor, proceed as

follows:

1. Set a VOM to a resistance scale that will allow a

range of about 20-60 ohms to be read. Zero the

meter.

2. Connect one VOM test leads to the "COM" termi

nal and the other test lead to Terminals G1, G2, G3

and G4 one at a time. Read the resistance as the

meter is connected to G1, to G2, to G3, and to G4.

RESISTANCE READING

"COM" to G1 s 20-60 Ohms

"COM" to G2 > 20-60 Ohms

"COM" to G3 o 20-60 Ohms

"COM" to G4 B 20-60 Ohms

3. Set the VOM to its “Rx1” scale and zero the

meter. Then connect the VOM test leads across

the “COM" terminal and the center screw. The

VOM should read “continuity”.

4. Now, connect the VOM test leads across the fol

lowing terminals and screws:

a. Across AC1 screw to AC1 terminal should

read “continuity”.

b. Across AC2 screw to AC2 terminal should

read “continuity”.

c. Across SLI screw to SLI terminal should read

“continuity”.

d. Across SL2 screw to SL2 terminal should read

“continuity”.

5. Set the VOM to its “Rxl 0,000” or “RxlK” scale

and zero the meter. Then, connect the VOM test

leads across each of the screws. There should be

no continuity between any of the screws (“infini

ty”).

NOTE: The resistance reading between any two of

the screws on the Genistor is in the neighborhood

of about 1 megohm (about 1 million amps). If the

Genistor

failed

any

of

the

proceeding

tests,

it

should be replaced.

f^lgure 4. Genistor Test Points

Testing the Battery Charge Circuit

GENERAL:

The Stator Is equipped with

dual battery charge windings.

These windings deliver an AC

output to a Battery Charge Rec

tifier (BCR) which rectifies it

É

changes It to direct current or

C). The direct current Is deliv

ered to the unit battery, to main

tain the battery in a charged

state while the unit Is running.

figure 5,

BATTERY CHARGE

WINDING

BCR

Page 1.5-3